Gearbox & axle assembly – Earthway C22HDS Stainless Steel Professional 50lb/23kg Broadcast Spreader User Manual

Page 2

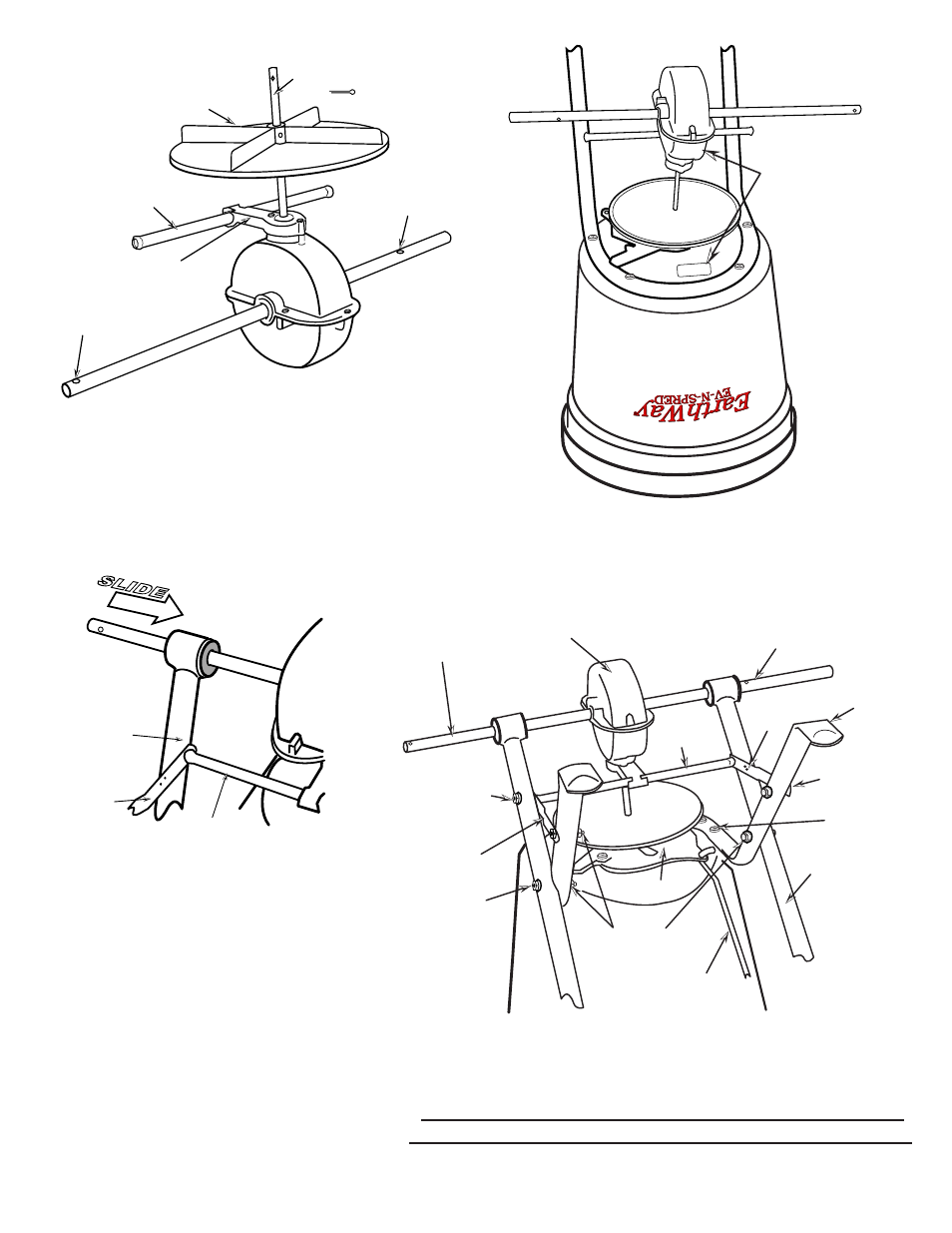

3. Install impeller onto pinion shaft. Insert 1/8” x 1¼” cotter pin

through impeller then through pinion shaft. Use hole nearest gear box.

Spread cotter pin to prevent from falling out. Next, install the Cross

Brace through the Gearbox Brace Support as shown above.

FRON

T

Pinion

Shaft

⅛ x 1¼”

Cotter Pin (#36105)

DRIVE WHEEL

HOLE

COAST WHEEL

HOLE

Impeller

Cross Brace

Gearbox & Axle Assembly

Gearbox Brace

Gearbox

FRONT

FRONT

FR

ON

T

4. Install Gearbox by inserting the pinion shaft into hole in center of

hoppers bottom. The word “FRONT” on the gearbox must point to

FRONT of the hopper.

SLIDE

Gearbox

Axle Assembly

Lower Handle

Frame Brace

Cross Brace

Gearbox & Axle Assembly

DRIVE WHEEL SIDE

COAST WHEEL SIDE

Frame brace

¼-20 x 1½”

Hex Head Bolt

and cupped washer

Step 5B

Step 5C

¼-20 x 2¼”

Hex Head Bolt

and cupped washer

Step 5A

¼-20 Lock nut

and cupped washer

Impeller

Cross Brace

Dimples

Frame

Lower Handle

Pivot Rod

Shut-Off

#14 x 1½”

Flat Head Screw

¼-20 x 1½”

Hex Head Bolt

5. Install Lower Handles onto Axle to both sides as

shown above.

A. Now insert 2¼” bolt through second hole in lower

handle and through first hole in frame and secure with

locknut.

DO NOT TIGHTEN YET.

B. Now insert 1½” bolt through first hole in lower

handle, then through frame brace, and finally into the

threaded connector in the Cross Brace. [NOTE: Dimples

on frame braces must be facing toward gearbox as

shown.]

C. Next insert 1½” bolt through other end of frame brace

and through second hole in frame install locknut.

DO NOT TIGHTEN YET.

PAGE 2

NOW GO BACK AND TIGHTEN ALL NUTS AND BOLTS

STARTING WITH FIRST STEP. DO NOT OVER TIGHTEN.

~~N

otice

cupped

washer

locatioNs

~~