FEC AFC1200 User Manual

Page 17

)(& ,QF

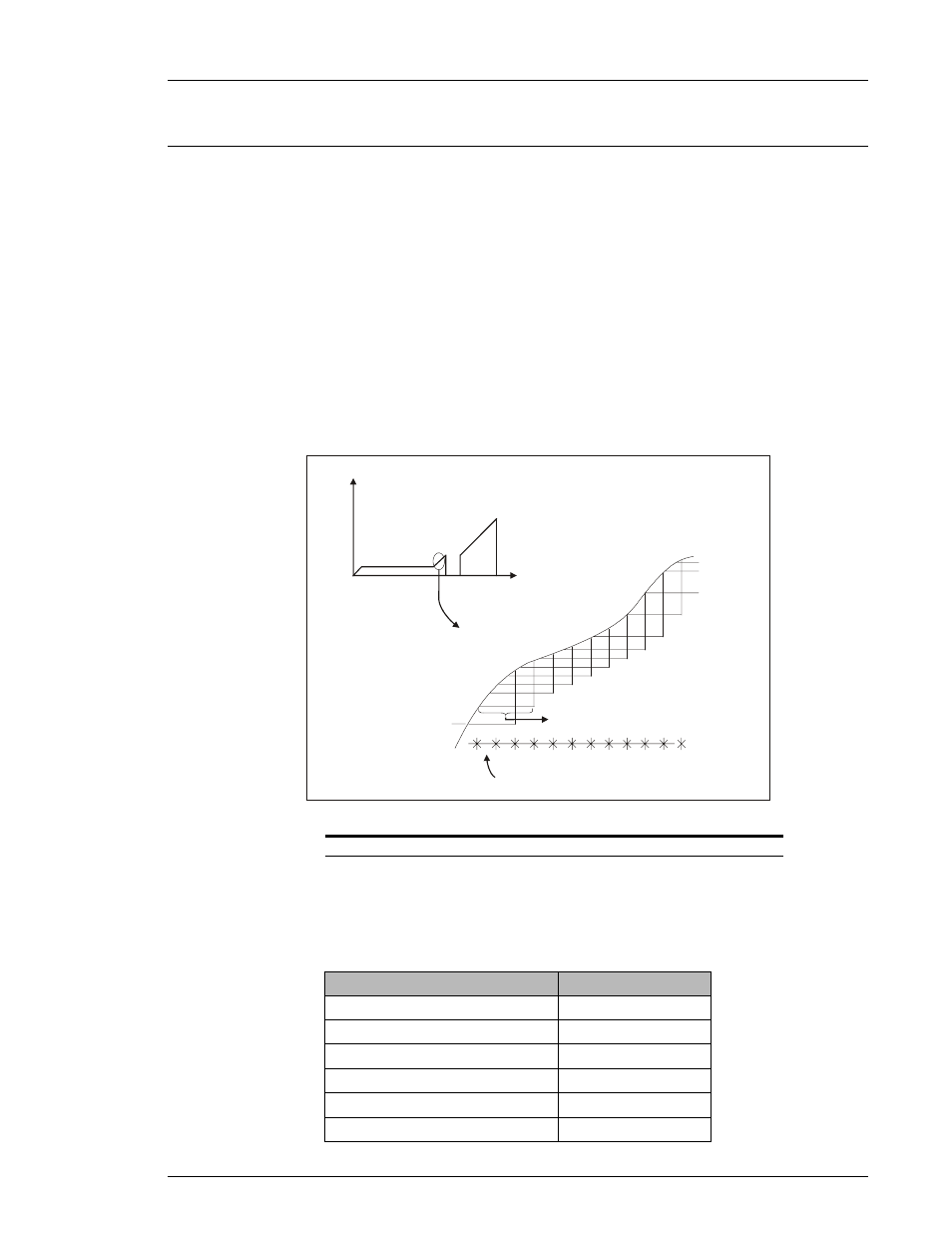

6.2.4 Integrated Torque Rate Method

The AFC1200 System is capable of performing three (3) independent torque rate calculations

using two (2) different procedures for calculating the rate value. The second of these

procedures is the Integrated method. The Incremental Torque Rate Method is enabled

whenever a value (3 ~ 199 odd number) is entered for the INCREMENT ANGLE on the SET

PARAMETER (FASTENING) screen. This method continuously calculates the torque rate for

the period specified by the INCREMENT ANGLE. Each one degree, the actual torque rate is

compared with the preset high and low torque rate values. The calculation is performed until

the end of the stage is reached or until a failure occurs, whichever occurs first. Each

Incremental Torque Rate is calculated by dividing the change in torque during the specific

period (INCREMENT ANGLE) by the INCREMENT ANGLE.

Example:

Deg

5 Deg

Nm

= 0.50

2.5 Nm

MAGNIFIED

FASTENING TQ CURVE

TQ

THRESHOLD 1 TORQUE

INCREMENT ANGLE

1 DEGREE

FIG. 6-2-4a Integrated Torque Rate Method Incremental Sampling

If no judgment is desired for any or all stages, the high and low limit values should be deleted

from the PARAMETER SET screen by first selecting the item, then depressing the DEL key

on the keyboard. Upon completion of the fastening process, the System will output the highest

and lowest incremental torque rate value measured during each stage. These values will be

output as 1st, 2nd and 3rd RATE HIGH and LOW.

3rd Rate High

Maximum 3rd Torque Rate

3rd Rate Low

Minimum 3rd Torque Rate

2nd Rate High

Maximum 2nd Torque rate

2nd Rate Low

Minimum 2nd Torque Rate

1st Rate High

Maximum 1st Torque Rate

1st Rate Low

Minimum 1st Torque Rate

NAME AS OUTPUT

DATA

Chapter 6: Fastening Instructions

Page 6-17