1 integrated yield method – FEC AFC1200 User Manual

Page 11

)(& ,QF

6.1.3 Yield Control Method (U.S.A. PATENT No. 4,894,767)

In Yield Control method, fastening is performed based upon attaining a desired permanent

elongation or bolt stretch. Fastening can be performed in from 1 to 4 incremental steps that

will successively secure the fastener to a specified torque or angle value before attaining the

final permanent elongation or bolt stretch. Incremental fastening steps should not be

performed if they will occur after Yield Control is initiated. Yield Control commences when

CROSSOVER RATE 2 (TORQUE or ANGLE) or CROSSOVER AREA (TORQUE or ANGLE)

is reached or exceeded. The Yield Control method is used primarily when greater control of

clamp load is required (connecting rods, main bearing caps, and cylinder heads, for

example).

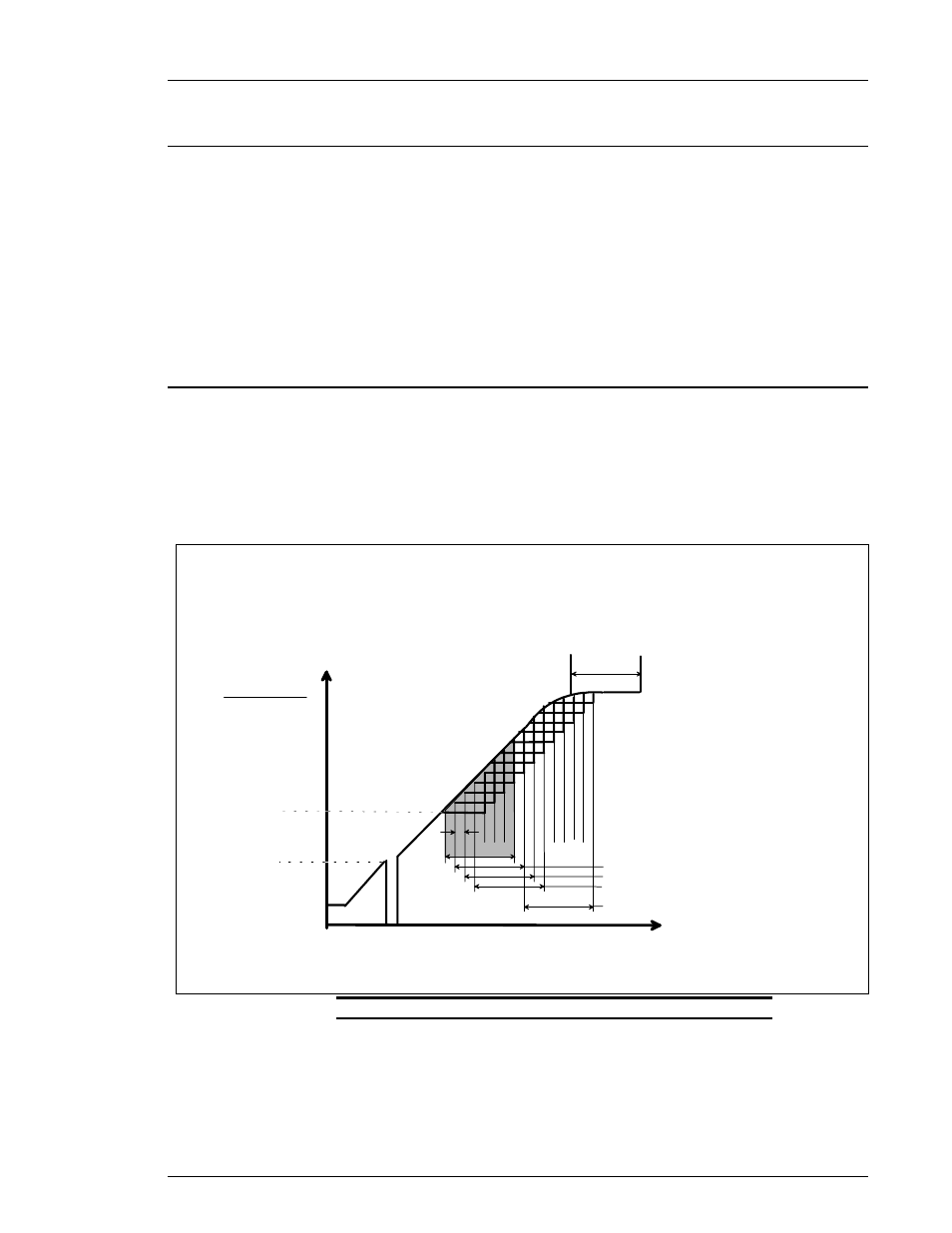

6.1.3.1 Integrated Yield Method

The integrated yield method will be the primary controlling method for fasteners that have a

clearly definable yield point. This type of fastener will exhibit a torque rate equal to

approximately zero (0) after the yield point has been detected. This rate will remain relatively

constant for the period specified by the elongation angle (ANGLE), at which point the fastener

will have attained the proper bolt stretch (LENGTH).

FIG. 6-1-3-1 Yield Control Function for Integrated Yield Method

Chapter 6: Fastening Instructions

Page 6-11

T1

T8

T7

T6

T5

T4

T3

T2

1

o

ANGLE

AFTER 1

AFTER 2

AFTER 3

AFTER 8

o

o

o

o

EVERY ONE DEGREE,

NEW TORQUE DATA IS

ADDED INTO THE EQUATION

AND THE OLDEST TORQUE

DATA IS OMITTED.

CROSSOVER

RATE 2

TORQUE / ANGLE

TORQUE / ANGLE

SCREW PITCH

LENGTH

ANGLE

YIELD RATE

CONSTANT

TORQUE

<

FOR PERIOD EQUAL TO THE

ELONGATION ANGLE (ANGLE)

ACTUAL AVERAGE TORQUE RATE YIELD RATE

(ANGLE)

1ST

PRESET ITEMS