Maintenance and service – SPP Pumps Unistream User Manual

Page 9

Operators Instructions for

Unistream Centrifugal Pumps

Manual No/Rev

W21-002E / 10

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 9 of 24

signal can still be heard with ear defenders

worn.

Hazardous Gases, Mists, Sprays

and Leaks

Be aware of the hazards relating to

the pumped fluid, especially the danger from

inhalation of noxious and toxic gases, skin

and eye contact or penetration. Obtain and

understand

the

hazardous

substance

(COSHH) data sheets relating to the

pumped fluid and note the recommended

emergency and first aid procedures.

Periodic Checks:

a) Stuffing Box:

Check that there is sufficient leakage to

lubricate and cool the packing, between 30

and 120 drops per minute is required. Check

also that the drain pipes are clear of

obstruction.

b) Bearings:

Check the bearing temperatures do not

exceed 70°C as an increase may indicate

the early stages of bearing trouble.

c) Noise:

Listen for any unusual noise or an increase

in normal sound level.

This may result from:

i)

Loose fasteners for guards and other

equipment.

ii)

Worn coupling.

iii) Air trapped in the pump i.e. the pump

was not fully primed.

iv) Cavitation caused by air in the liquid

from leaks in the suction pipework.

v)

Small solids in the liquid.

NOTE - At certain installations or at certain

operation points on the pump curve, the

noise level 70dB (or the actual pump

specified noise level) can be exceeded.

d) Alignment:

Alignment should be checked after the first

run and after any maintenance requiring

removal or disconnection of the coupling.

For detailed instructions, refer to Section 4.5

- Shaft Alignment

e) Suction Gauge Reading:

If this is higher than normal, investigate and

check that valves in the suction pipework are

fully open or that the suction lift may have

increased.

f) Discharge Gauge Reading:

If this is lower than normal, check for a leak

in the associated pipework or that a valve in

the delivery line has been opened when

normally it is partially closed.

5.3 Stopping Procedure

Stop the motor then fully close the discharge

valve.

6. Maintenance and Service

6.1 General Introduction

SPP Pumps Ltd Unistream pumps will

provide many years of trouble free service

when maintained in accordance with these

instructions. In the event of failure of the

pump it is recommended that SPP Pumps

Ltd. Service Department is called to

investigate and carry out repairs. The

following instructions are given to cover the

main elements of strip and rebuild but do

NOT include instructions for work that MUST

be done by an SPP Pumps Ltd. Service

Engineer.

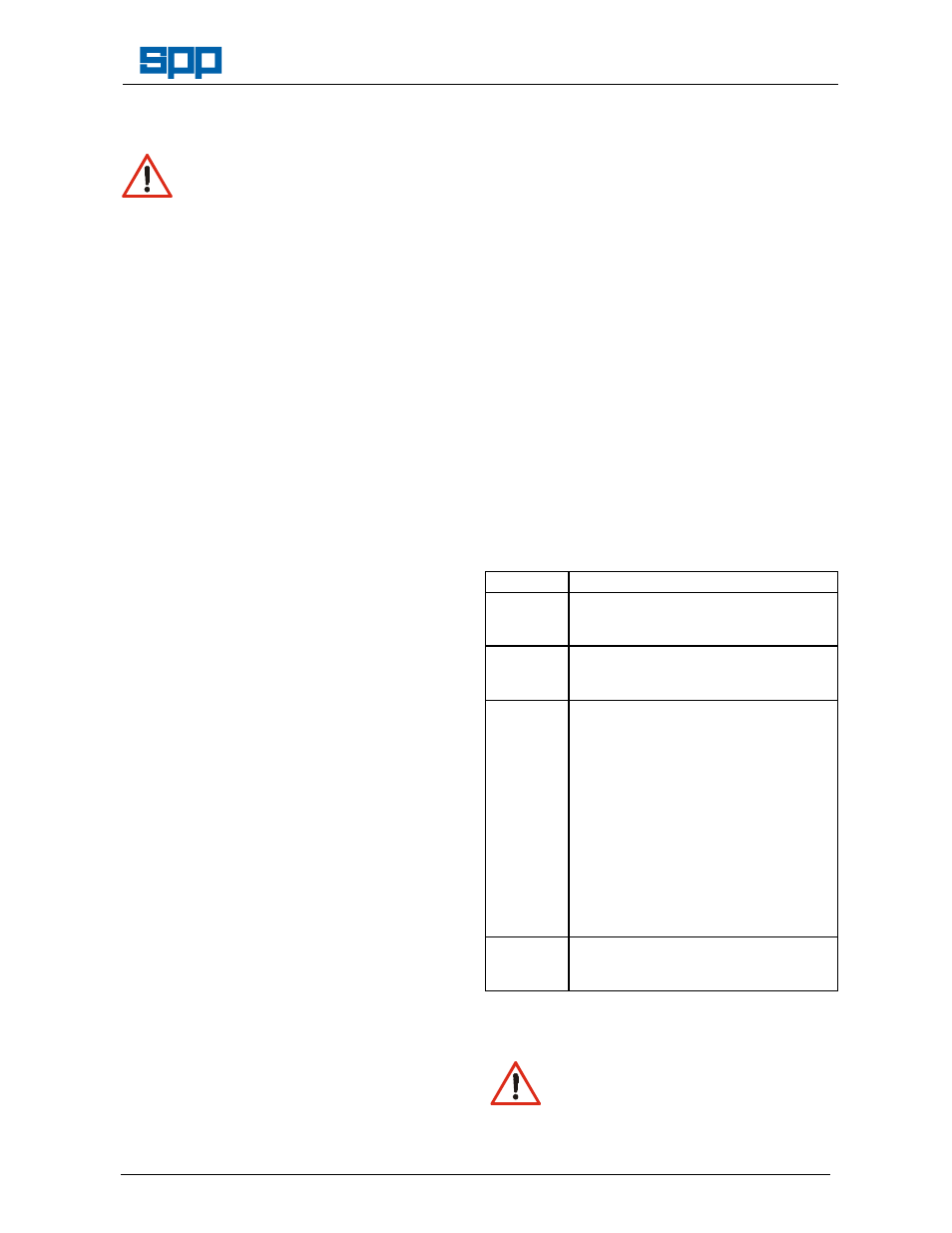

Recommended Maintenance Schedule

Period:

Maintenance Required:

Weekly

Carry out periodic checks as shown in

Section 5.3 and take corrective action

as shown in Section 7.

After First

200 Hours

Running

Replace the Lubricating Oil as shown in

Section 6.4.

Half Yearly

or After

5000

Hours

Running

Replace the Lubricating Oil as shown in

Section 6.4.

Check the alignment of pump and motor

and adjust, as shown in Section 4.5.

Check and tighten all holding down bolts

if found loose, refer to Section 9 for

recommended bolt tightening torques.

For soft packed pumps, check the gland

adjustment remaining and replace

packing if necessary. At the same time,

check the sleeve for scoring and replace

if necessary.

Check the coupling for wear as per

manufacturers instructions.

Each Year Assess the performance of the pump

against the duty specifications and take

corrective action as shown in Section 7

The following hazards may arise during

maintenance work:

Fluid Pressure Jet Hazards

Check and ensure that the pump

operates at below the Maximum

Working Pressure specified in the manual or

on the pump nameplate and before

maintenance, ensure that the pump is