SPP Pumps Unistream User Manual

Page 10

Manual No/Rev

W21-002E / 10

Operators Instructions for

Unistream Centrifugal Pumps

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 10 of 24

drained down.

Hazardous Materials

Wear a suitable mask or respirator

when working with Packing and

Gasket components that contain

fibrous material, as these can be hazardous

when the fibrous dust is inhaled. Be

cautious, if other supplier's components

have been substituted for genuine SPP

Pumps Ltd parts, these may then contain

hazardous materials.

Hazardous Gases, Mists, Sprays

and Leaks

Be aware of the hazards relating to

the pumped fluid, especially the danger from

inhalation of noxious and toxic gases, skin

and eye contact or penetration. Obtain and

understand

the

hazardous

substance

(COSHH) data sheets relating to the

pumped fluid and note the recommended

emergency and first aid procedures.

BEFORE ATTEMPTING ANY MAINTENANCE ON

A PUMP, PARTICULARLY IF IT HAS BEEN

HANDLING ANY FORM OF HAZARDOUS

LIQUID, ENSURE THAT THE UNIT IS SAFE TO

WORK ON. THE PUMP MUST BE FLUSHED

THOROUGHLY WITH A SUITABLE CLEANSER

TO PURGE AWAY ANY OF THE PRODUCT

LEFT IN THE PUMP COMPONENTS. THIS

SHOULD BE CARRIED OUT BY THE PLANT

OPERATOR

AND

A

CERTIFICATE

OF

CLEANLINESS OBTAINED BEFORE STARTING

WORK. TO AVOID ANY RISK TO HEALTH IT IS

ALSO ADVISABLE TO WEAR PROTECTIVE

CLOTHING AS RECOMMENDED BY THE SITE

SAFETY

OFFICER,

ESPECIALLY

WHEN

REMOVING OLD PACKING THAT MAY BE

CONTAMINATED.

6.2 Preparation for Maintenance

Electric Shock & Accidental

Starting Hazard

ISOLATE the equipment before

any maintenance work is done.

Switch off the mains supply, remove fuses,

apply lockouts where applicable and affix

suitable isolation warning signs to prevent

inadvertent re-connection.

In order to avoid the possibility of

maintenance personnel inhaling dangerous

fumes or vapours. It is recommended that

maintenance work be carried out away from

the pump location by removal of the bearing

housing and shaft assembly to a suitable

maintenance area.

No special tools are required for dismantling

and re-assembling, however, it is important

to ensure the suitable lifting equipment is

available and that the work is carried out in a

clean area.

6.3 Re-packing the Stuffing Box

Where a soft packed gland is fitted, it will be

necessary to replace the packing periodically

when the gland can no longer be tightened

to reduce leakage to the normal level, or if

the gland suffers from overheating.

6.3.1 Removal and Preparation

Close the suction & discharge valves and

release pressure from the casing.

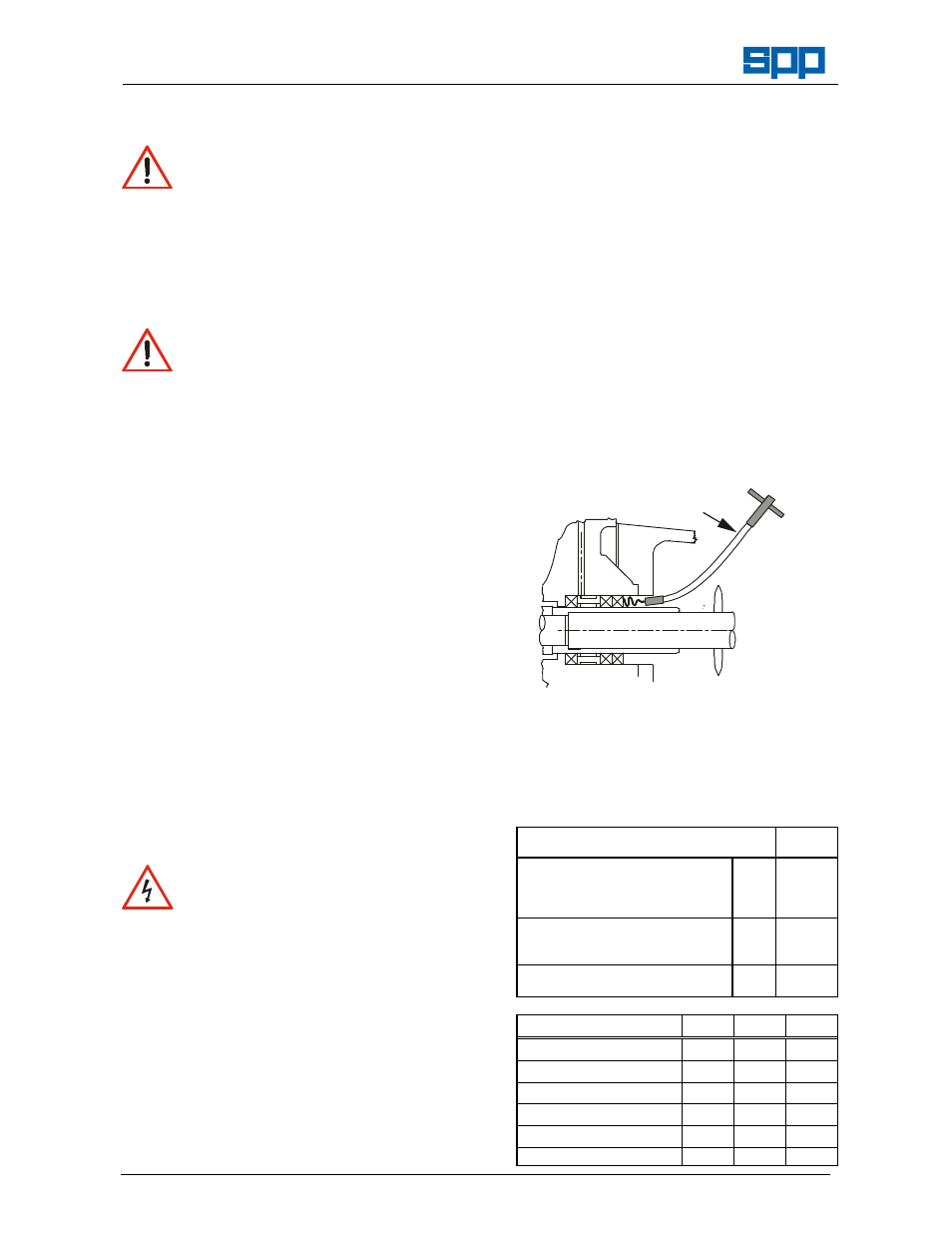

Remove the gland (45.2), use an extractor

tool to remove packing rings and remove the

lantern ring without damaging the sleeve or

stuffing box bore.

PACKREM1.CDR

PACKING REMOVAL TOOL

Clean the sleeve and bore of the stuffing box

with a clean oily cloth, also clean the lantern

ring.

6.3.2 Packing Preparation

Packing Ring Dimensions (mm)

Pump Size

Shaft

Unit

32/13

32/16

32/20

32/26

40/13

40/16

40/20

40/26

50/13

50/16

50/20

50/26

65/13

65/16

65/20

80/16

25

65/26

65/32

80/20

80/26

80/32

100/20

100/261

00/32

125/26

35

100/40

125/32

125/40

150/32

15040

45

Packing Ring Dimensions (mm)

Shaft Unit

25

35

45

Sleeve Dia. (Minus 0.1mm)

32

40

55

Box Dia. (Plus 0.1mm)

48

60

75

Length of Box

50

63

63

Cross Section of Packing

8 x 8

10 x 10 10 x 10

Length per Ring

125

156

203

Number Required with

4

4

4