General information and safety instructions – SPP Pumps Unistream User Manual

Page 3

Operators Instructions for

Unistream Centrifugal Pumps

Manual No/Rev

W21-002E / 10

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 3 of 24

CONTENTS

Section ........................................................ Page

1

General Information & Safety

Instructions ............................................ 3

2

Transport Handling and Storage ........... 4

3

General Description ............................... 5

4

Assembly and Installation ...................... 5

5

Commissioning and Operation .............. 7

6

Maintenance and Service ...................... 9

7

Faults and Remedial Action ................. 14

8

Pump Details: ...................................... 14

8.1 Pump Dimensions & Weights ........... 15

8.2 Pump Sections and Parts Lists ......... 15

8.3 Pump Connections ........................... 20

9

Additional Information .......................... 22

10

Bolt Torque Recommendations ........... 23

11

Spares and Service ............................. 24

Manufacturers Information:

(Where applicable)

Seal & Seal System .......................... Appendix I

Coupling .......................................... Appendix II

Electric Motor .................................. Appendix III

Introduction

This manual gives the safety, installation, operation

and maintenance instructions for pumps in the SPP

Pumps UNISTREAM range of horizontal, end

suction, centrifugal pumps for general and

industrial use

Pumps may be identified by the SPP Pumps code

typically in the form 'KP04E' or by the Equivalent

Standard pump code typically in the form '40/26'.

This manual applies to the following pump types:

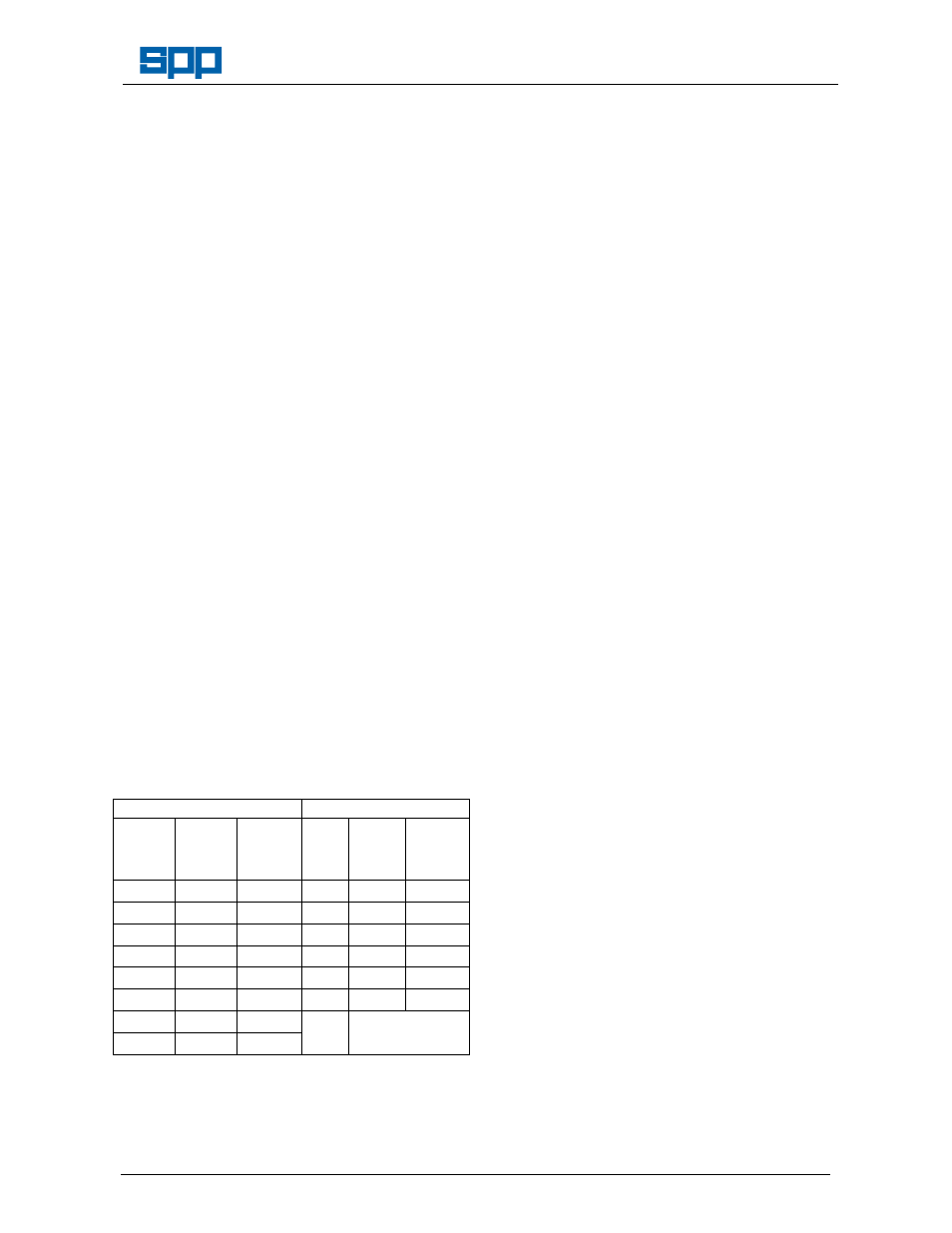

Pump Size Code

Type Suffix Letter

SIZE

Code

Delivery

Branch

Dia.

mm.

Standard

Size

Code

TYPE

Suffix

Nominal

Impeller

Dia.

mm.

Standard

Size

Suffix

KP03

32

32/**

B

125

**/13

KP04

40

40/**

C

160

**/16

KP05

50

50/**

D

200

**/20

KP06

65

65/**

E

250

**/26

KP08

80

80/**

F

315

**/32

KP10

100

100/**

G

400

**/40

KP12

125

125/**

V X Y These pumps are.

KP15

150

150/**

& Z

non-standard

Use this table to convert the pump type code into

the equivalent standard code to obtain information

for your pump from the manual. Note, for pump

types AV03N, KP08V & Y, KP10X & Y, KP12X & Z,

& KP15Y, please refer to separate manuals W21-

003E and W21-004E

1. General Information and Safety

Instructions

The products supplied by SPP Pumps Ltd. have

been designed with safety in mind. Where hazards

cannot be eliminated, the risk has been minimised

by the use of guards and other design features.

Some hazards cannot be guarded against and the

instructions below MUST BE COMPLIED WITH for

safe operation. These instructions cannot cover all

circumstances; YOU are responsible for using safe

working practices at all times.

1.1

SPP Pumps Ltd. products are designed for

installation in designated areas, which are to

be kept clean and free of obstructions that

may restrict safe access to the controls and

maintenance access points.

A pump nameplate is fitted to each unit and

must not be removed. Loss of this plate

could make identification impossible. This

in turn could affect safety and cause difficulty

in obtaining spare parts. Should accidental

loss or damage occur, contact SPP Pumps

Ltd. immediately.

1.2

Access to the equipment should be

restricted to the personnel responsible for

installation, operation and maintenance and

they must be trained, adequately qualified

and supplied with the appropriate tools for

their respective tasks.

1.3

SPP Pumps Ltd. requires that all personnel

that are responsible for installation, operation

or maintenance of the equipment, have

access to and study the product instruction

manual BEFORE any work is done and that

they will comply with all local and industry

based safety instructions and regulations.

1.4

Ear defenders should be worn where the

specified equipment noise level exceeds

locally defined safe levels. Safety glasses or

goggles should be worn where working with

pressurised

systems

and

hazardous

substances.

Other

personal

protection

equipment must be worn where local rules

apply.

1.5

Do NOT wear loose or frayed clothing or

jewellery that could catch on the controls or

become trapped in the equipment.

1.6

Check and confirm that the manual is the

relevant copy by comparing the serial

number on the identification plate with that

on the manual.