Commissioning and operation – SPP Pumps Instream User Manual

Page 6

Manual No/Rev

W23-001E / 8

Operators Instructions for

Instream Centrifugal Pumps

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 6 of 16

to prevent foreign matter from being drawn

into the pump. A screen or basket strainer

may also be required to hold back larger

items. These should be sized to maintain the

flow through them to below 0.6 m/s.

The suction pipe work must be flushed clean

to ensure that site debris is not drawn into the

pump when it is commissioned.

4.6

Discharge Pipework

The bore of the discharge pipe should be

sized to ensure a flow velocity of 2.5 to 3 m/s

is not exceeded. This is usually one size larger

than the discharge branch. Pipework should

be as short and straight as possible to reduce

friction head loss.

A non-return valve is usually fitted to prevent

the pump from excessive back pressure and

reverse rotation and a discharge valve is

usually fitted to regulate the flow and allow for

inspection and maintenance on the pump.

The suction and discharge pipework must be

independently supported and positioned such

that no excessive forces and moments are

exerted on the pump flanges.

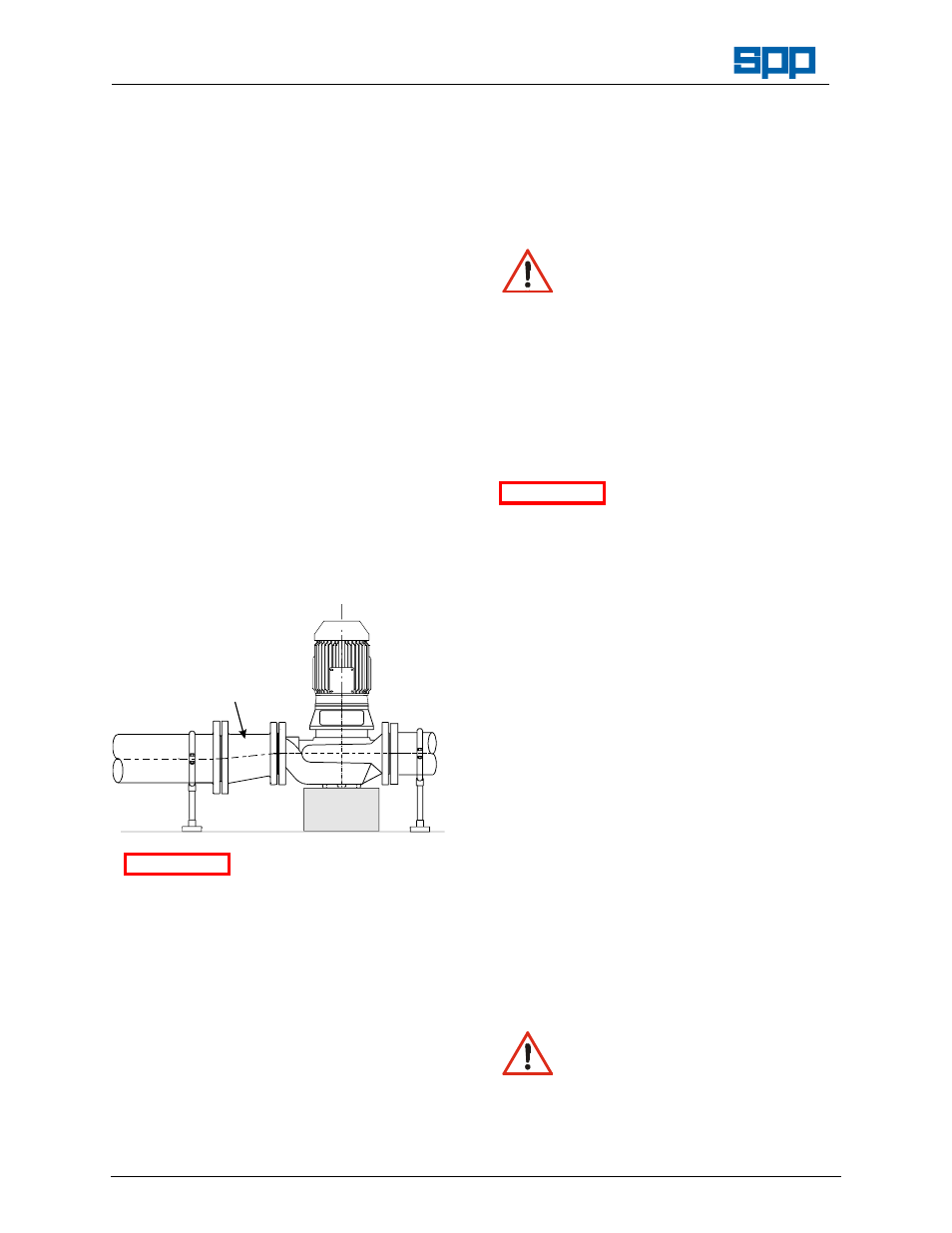

Preferred Pipework

INSTPIP1.WMF

Eccentric Reducer

Failure to support suction

and

delivery

pipework

may result in distortion of the pump casing,

with the possibility of early pump failure.

4.7

Foundations

The pump must be secured to substantial

foundations to minimise vibrations. After the

pump has run for about 200 hours, the

foundation bolt should be checked for

tightness.

The pump must be secured to substantial

foundations to minimise vibrations. After the

pump has run for about 200 hours, the

foundation bolt should be checked for

tightness.

5. Commissioning and Operation

5.1

Commissioning Checks

These checks must be done after first

installation and after pump maintenance that

required removal of the rotating assembly.

Abrasion and Entrapment Hazard

Do NOT touch any moving or

rotating parts. Guards are provided

to prevent access to these parts, where they

have been removed for maintenance they

MUST be replaced before operating the

equipment.

Check that the rotating assembly is free to

rotate by hand before connecting the power

supply. Also check that the piping system has

been properly connected with all joints

tightened and instrumentation is in position.

Check that the pump is

primed.

Pumps

should

never be run dry as the pumped liquid acts as

a lubricant for the close running fits

surrounding the impeller and damage will be

incurred.

Prime the pump using an ejector, exhauster or

vacuum pump. If a foot valve is used in the

suction line the pump may be primed by

venting and filling the casing with liquid. Open

the air release valve to bleed any air trapped

in the sea housing, as the seal must be

lubricated and dry running may contribute to

premature seal failure.

Connect the electrical supply to the pump unit.

Momentarily switch on motor and check

direction of rotation. This should be such that

the pump assembly turns clockwise when

viewed on the driven end. For three phase

electric motors, if direction of rotation is

incorrect, disconnect the supply and change

over two of three supply wires.

5.2

Starting Procedure

BEFORE AN INSTREAM PUMP IS STARTED

ALWAYS ENSURE THAT THE SUMP IS FILLED

TO THE CORRECT LEVEL WITH LIQUID, AND

THAT

ANY

LEVEL

CONTROLS

ARE

FUNCTIONING CORRECTLY.

Abrasion and Entrapment Hazard

Do NOT touch any moving or

rotating parts. Guards are provided

to prevent access to these parts, where they

have been removed for maintenance they

MUST be replaced before operating the

equipment.

ATTENTION

ATTENTION