Faults and remedial action – SPP Pumps Instream User Manual

Page 11

Operators Instructions for

Instream Centrifugal Pumps

Manual No/Rev

W23-001E / 8

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 11 of 16

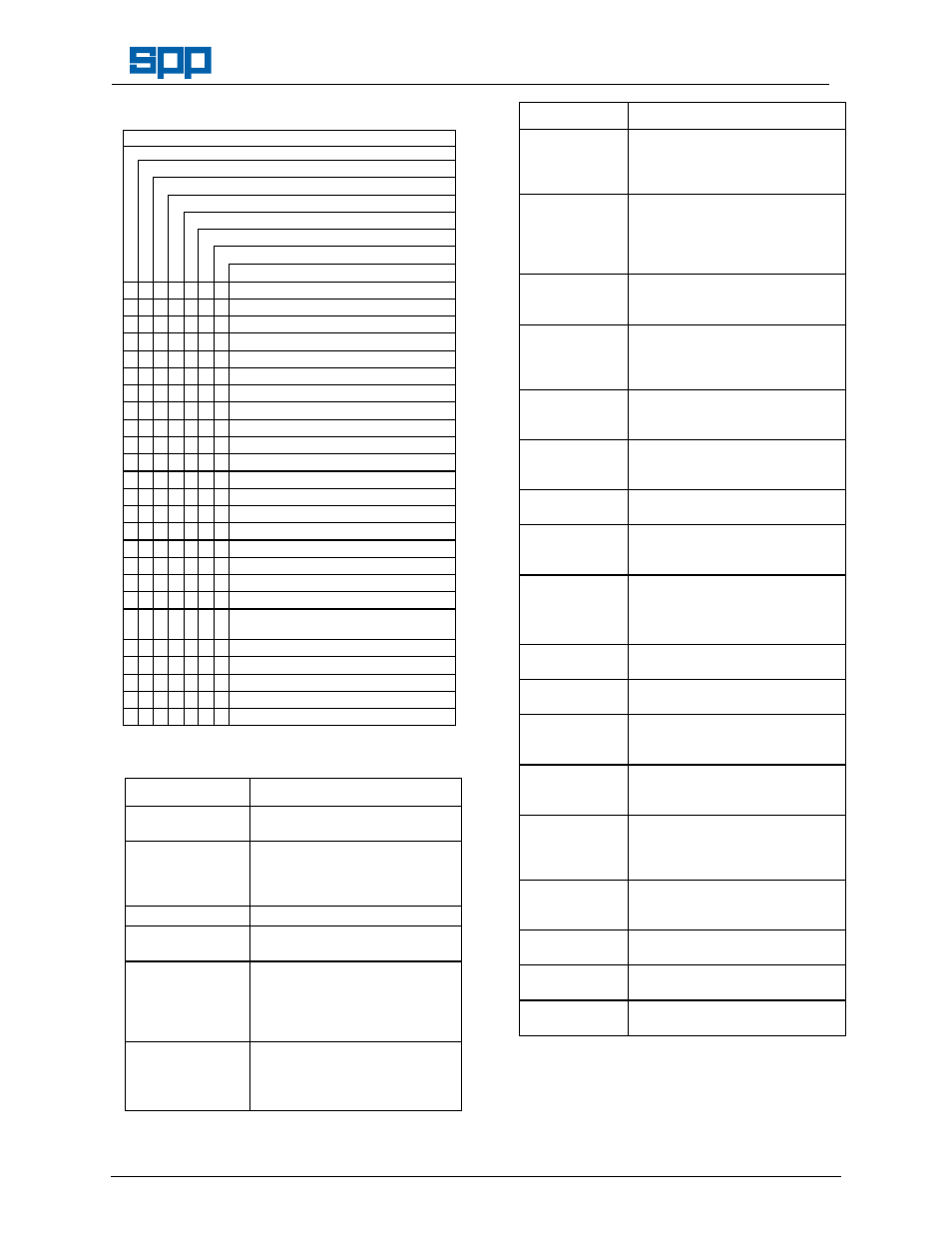

7. Faults and Remedial Action

POTENTIAL FAULT OR DEFECT:

No liquid delivered.

Insufficient liquid delivered.

Liquid delivered at low pressure.

Loss of liquid after starting.

Excessive vibration.

Motor runs hotter than normal.

Excessive noise from pump cavitation.

PROBABLE CAUSES

Pump not primed.

Speed too low.

Speed too high.

Air leak in suction pipework.

Air leak in mechanical seal.

Air or gas in liquid.

Discharge head too high (above rating).

Suction lift too high.

Not enough head for hot liquid.

Inlet pipe not submerged enough.

Viscosity of liquid greater than rating

Liquid density higher than rating.

Insufficient nett inlet head.

Impeller plugged up or blocked.

Wrong direction of rotation.

Excessive wear ring clearance.

Damaged impeller.

Rotor binding.

Defects in motor.

Voltage and/or frequency lower than

rating.

Foundation not rigid.

Misalignment of pump and driver.

Rotor out of balance.

Shaft bent.

Impeller too small.

For remedial action refer to the following tables:

CAUSE

REMEDIAL ACTION

Pump not primed.

Fill pump and suction pipe

completely with fluid.

Speed too low.

Check that the motor is correctly

connected and receiving the full

supply voltage also confirm that

the supply frequency is correct.

Speed too high.

Check the motor voltage.

Air leak in suction

pipework

Check each flange for suction

draught, rectify as necessary.

Air leak in

mechanical seal.

Check all joints, plugs and

flushing lines, if fitted. Note that

prolonged running with air in the

mechanical seal will result in

damage and failure of the seal.

Air or gas in liquid. It may be possible to increase the

pump performance to provide

adequate pumping.

CAUSE

REMEDIAL ACTION

Discharge head

too high (above

rating).

Check that valves are fully open

and for pipe friction losses. An

increase in pipe diameter may

reduce the discharge pressure.

Suction lift too

high.

Check for obstruction of pump inlet

and for inlet pipe friction losses.

Measure the static lift, if above

rating, raise the liquid level or

lower the pump.

Not enough

head for hot

liquid.

Reduce the positive suction head

by raising the liquid level.

Inlet pipe not

submerged

enough.

If the pump inlet cannot be

lowered, provide a baffle to

smother the inlet vortex and

prevent air entering with the liquid.

Liquid density

higher than

rating.

Refer to SPP Pumps Ltd. for

guidance to increase the size or

power of the motor or engine.

Insufficient nett

inlet head.

Increase the positive suction head

by lowering the pump or raising

the liquid level.

Impeller

blocked.

Dismantle pump and clean the

impeller.

Wrong direction

of rotation.

Check driver rotation with the

direction arrow on the pump

casing.

Excessive wear

ring clearance.

Replace the wear rings when the

clearance exceeds the maximum

tolerances.

Damaged

impeller.

Replace if damaged or vanes are

eroded.

Rotor binding.

Check for shaft run out, and

replace if necessary.

Defects in

motor.

Ensure that motor is adequately

ventilated. Refer to manufacturers

instructions.

Voltage and/or

frequency lower

than rating.

If voltage and frequency are lower

than the motor rating, arrange for

provision of correct supply.

Foundation not

rigid.

Ensure that the foundation bolts

are tight; check that foundations

match SPP Pumps Ltd.

Recommendations.

Misalignment of

pump and

driver.

Check shaft run-out and replace if

necessary.

Rotor out of

balance.

Check impeller for damage,

replace as necessary.

Shaft bent.

Check shaft run-out and replace if

needed.

Impeller too

small.

Refer to SPP Pumps Ltd. for

options to fit a larger impeller.