General description, Assembly and installation, Trapped air unsupported pipe – SPP Pumps Instream User Manual

Page 5

Operators Instructions for

Instream Centrifugal Pumps

Manual No/Rev

W23-001E / 8

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 5 of 16

3. General Description

The SPP Pumps Ltd range of Instream Pumps

are centrifugal pumps that comply with Pump

Standard DIN24255.

The mechanical assembly comprises an

electric motor fitted with an extended shaft to

carry a double shrouded type impeller. This is

connected by a support frame to an in line

volute casing fitted with wear ring(s). The

motor, frame, shaft and impeller assembly can

be withdrawn from the volute for maintenance

without disconnection of pipe work.

The in line suction and discharge branches

are the same size. The pump must be

mounted with the motor shaft vertical and

above the pump. A mounting position is

provided on the volute casing for attachment

to suitable foundations.

The shaft is sealed with a standard

mechanical seal.

Nameplate details are shown on the back

cover, full pump specification can be supplied

on a data sheet, if requested.

Note

(1) - Head specified is the Duty Head generated by the

pump only.

(2) -Suction pressure must be included when assessing the

Maximum Working Pressure.

For details of the motor supplied, refer to the

manufacturer's instructions in Appendix I.

4. Assembly and Installation

Shearing Hazard

Do NOT place fingers or hands etc.

into the suction or discharge pipe

outlets and do NOT touch the

impeller, if rotated this may cause severe

injury. To prevent ingress of any objects,

retain the protection covers or packaging in

place

until

removal

is

necessary

for

installation.

4.1

Initial Inspection for Damage

During transport and storage, accidental

damage to the pump may have occurred.

When the pump is to be installed, or in the

event of a handling accident, carefully check

that no damage has been sustained by the

pump before installation and commissioning.

4.2

Preparation for Mounting

Before installation, check that the pump

mounting location is suitable for accepting the

pump. Refer to Section 8, for details of pump

installation dimensions or to a certified

General

Arrangement

Drawing

when

available.

4.3

Pump Preparation

Abrasion & Entrapment Hazard

Do NOT touch any moving or rotating

parts. Guards are provided to prevent

access to these parts, where they have been

removed for maintenance they MUST be

replaced before operating the equipment.

Remove packaging but leave the flange

covers in place, check that impeller rotates

freely by hand by turning the shaft.

4.4

Pump Installation

Instream pumps are to be mounted on

substantial

rigid foundations to reduce

vibrations. A bolt hole is provided within a

circular foot for fixing to a baseplate or

framework.

4.5

Suction Pipework

The run of suction pipework must be such that

air can NOT become trapped where it would

be sucked into the pump on starting. The bore

of suction pipe is recommended to be one or

two sizes larger than the pump suction branch

and reducers if used must be eccentric to

eliminate the possibility of an air pocket being

formed.

Bends in the suction pipeline should be as

large as possible, the pipe made as short and

as straight as possible and all joints must be

fully air tight. If fitting a foot valve, it should

have a free area of one and a half times the

area of the suction pipe.

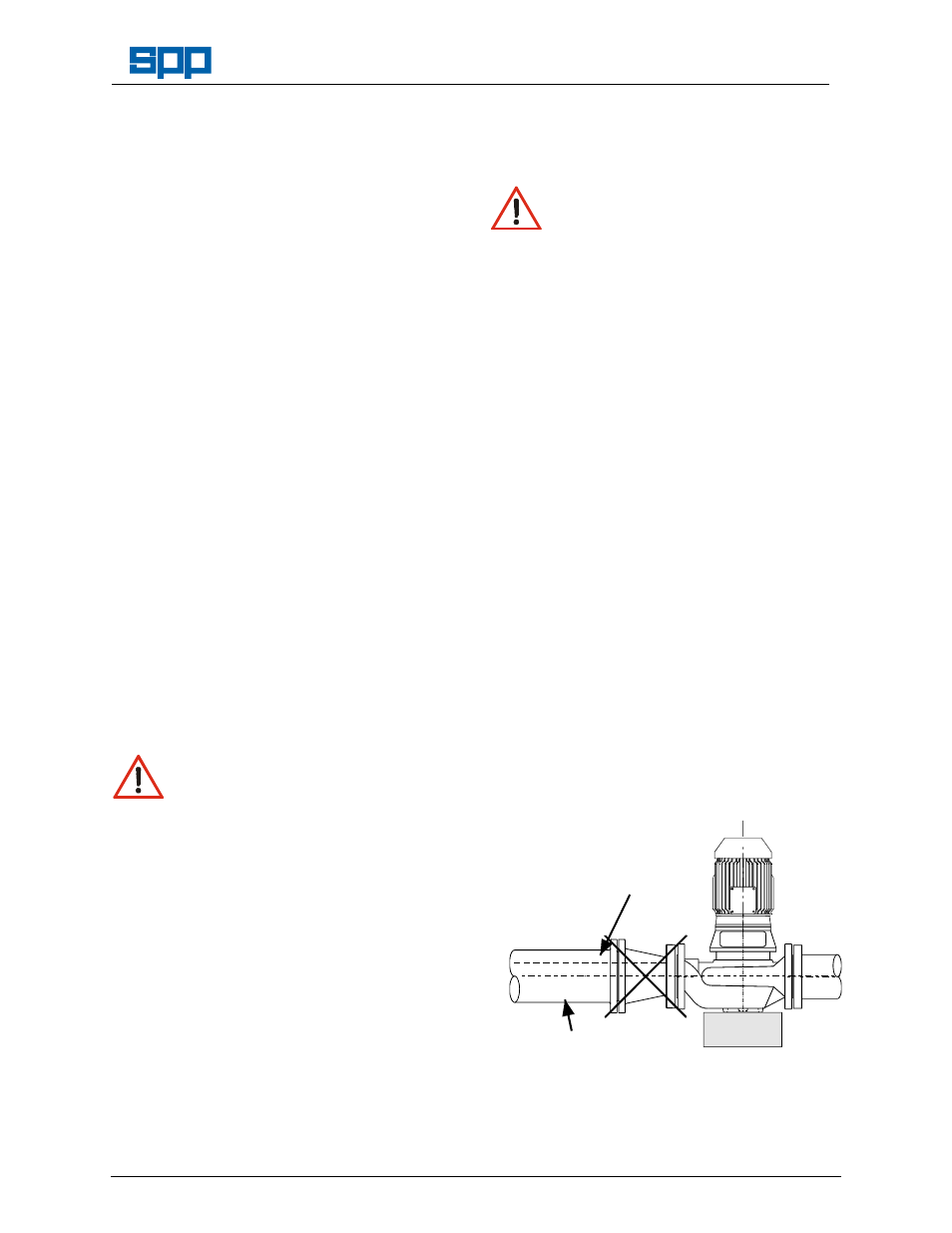

Unacceptable Suction Pipework

Trapped Air

Unsupported Pipe

INSTSUC1.WMF

Where pumping water at temperatures above

70°C, care must be taken to ensure that

enough pressure is available at the impeller

entry to prevent vaporisation.

An appropriate fine strainer is recommended