SPP Pumps Instream User Manual

Page 10

Manual No/Rev

W23-001E / 8

Operators Instructions for

Instream Centrifugal Pumps

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 10 of 16

2.

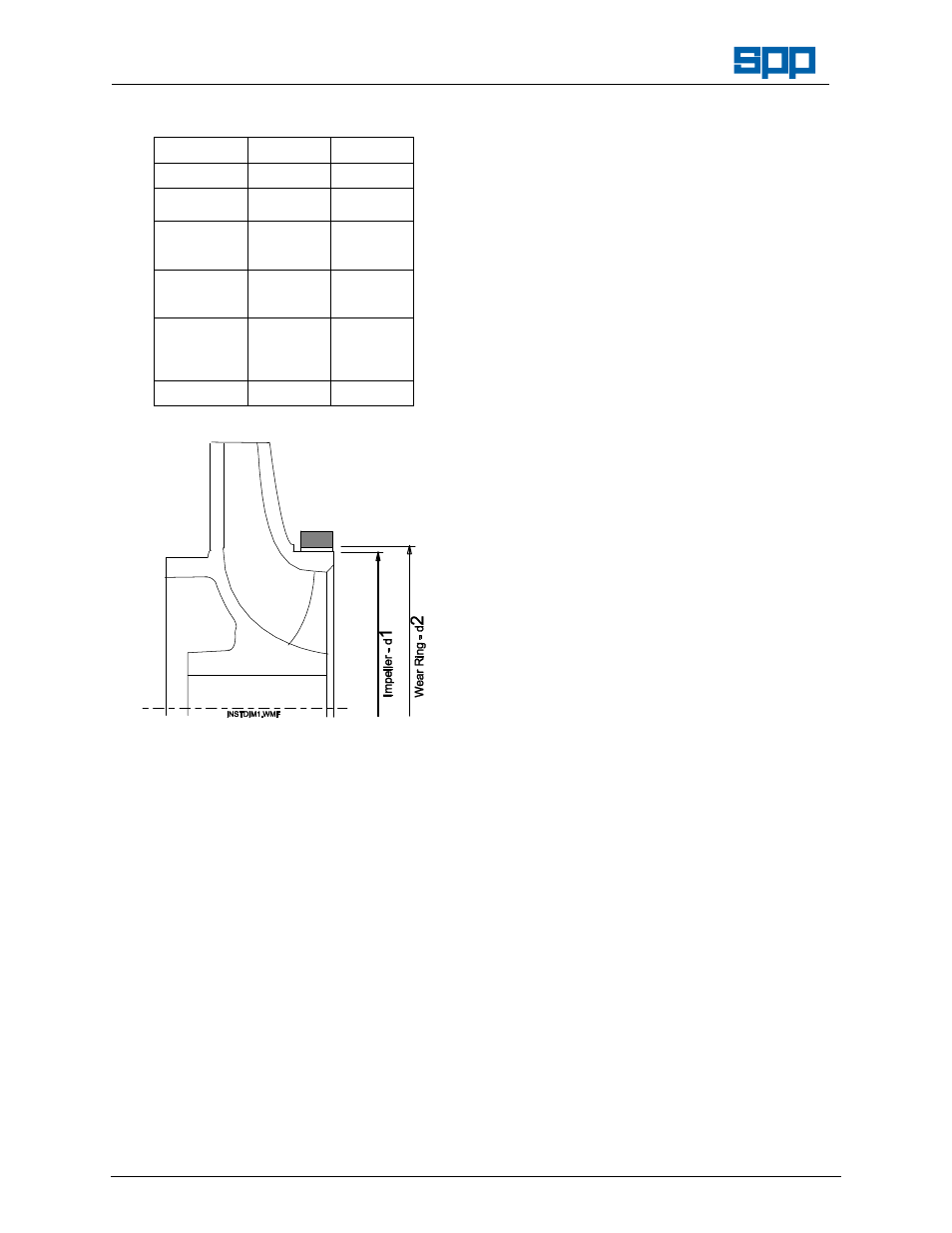

Wear Ring Diameters.

Pump Size

Dia. 1

Dia. 2

Tolerance

- 0.1mm

F8

40/13

40/16

69.7

70

50/13

50/16

50/20

79.7

80

65/13

65/16

65/20

94.7

75

80/13

80/16

80/20

80/26

114.7

115

100/16

129.6

130

6.3.4 Reassembly

1.

Ensure that all parts to be fitted are clean and

free from burrs, with screw threads and

abutting faces clear and free from damage.

2.

Lubricate the outer surface of the stationery

element of the mechanical seal (43.3) with

soapy water or silicone grease (not oil),

ensure that it is square to its housing in the

casing cover (16.1) and push home by hand,

taking care not to apply excessive force or to

damage the sealing surface. Check that it has

been seated fully and that the sealing surface

is clean and undamaged.

3.

Refit the casing cover (16.1) to the support

frame (34.4). for bolted covers only, fit the

retaining

nuts

(92.02), tightening them

uniformly and in diagonally opposed pairs

sequence.

4.

Fit the rotating element of the mechanical seal

(43.3) thus:

Lubricate the inner and outer surfaces of the

sleeve lightly with silicone grease. Locate

spring and spring holder of mechanical seal

over shaft sleeve (52.3).

Slide seal face assembly along sleeve (52.3)

up to the spring.

Slide shaft sleeve (52.3) over shaft (21.1),

larger bore first, ensuring that mechanical seal

faces are clean, free from damage and square

and that gasket (40.01) is correctly seated.

Ensure that the rotating seal face is floating

against the spring before re-fitting the impeller.

5.

Locate impeller key (94.01) into shaft key way.

Relocate impeller (23.0) on shaft (21.1). Refit

impeller lockwasher (93.0) and screw on

impeller nut (92.2) and carefully tighten.

6.

Ensure impeller rotates freely by hand. If not

investigate and rectify. Relocate casing cover

(16.1) into casing (10.2), using casing studs

(90.2), ensuring that gasket (40.0) is seated

correctly.

Fit nuts (92.0) and tighten uniformly in

diagonally opposed pairs sequence.

Fit and tighten the motor mounting bolts.

Reconnect supply, ensuring correct pump

rotation