Maintenance & service instructions – SPP Pumps Auto Prime Q Series - QI200 User Manual

Page 10

Manual No/Rev

W72-008E / 9

Operators Instructions for

AUTOPRIME Q Range Pump Unit

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 10 of 18

7. MAINTENANCE & SERVICE INSTRUCTIONS

.

These instructions are for trained pump

service engineers.

Where instructions in this section are

followed by (LH) or (RH) this indicates either

the left hand or right hand side of the unit

looking from the pump (towbar) end

7.1 Preparation for Maintenance

Electric Shock & Accidental Starting

Hazard ISOLATE the equipment from any

mains

supply

connected

before

any

maintenance work is done.

For diesel engine driven pumps disconnect

the negative battery lead to prevent

inadvertent starting.

To avoid the possibility of maintenance

personnel inhaling dangerous fumes or

vapours.

It

is

recommended

that

maintenance work be carried out away from

the pump location by removal of the pump

unit to a suitable maintenance area.

No special tools are required for dismantling

and re-assembling, however, it is important

to ensure the suitable lifting equipment is

available and that the work is carried out in a

clean area.

7.2 Pump Bearings

The pump shaft runs on three bearings: a

roller bearing on the impeller end of the shaft

and a pair of angular contact bearings on the

drive end of the shaft. These bearings are

grease lubricated.

BRGHSGA

DRIVE END

GREASE

NIPPLE

PUMP END

GREASE

NIPPLE

Grease is applied through two grease

nipples, one for the roller bearing and one for

the pair of angular contact bearings located

on the left side of the bearing bracket. Do

not over grease. Ten strokes (15 grams) of a

hand held grease gun at the specified

intervals are sufficient.

7.3 Mechanical Seals

The mechanical seals are cooled and

lubricated by oil. The oil reservoir is mounted

on top of the non-return valve cover. The

system oil capacity is approximately two

litres. The bottle should be filled to the MAX

mark when the unit is cold.

Only use oil of the correct grade

(see Technical Data section).

7.4 Fuel Filler Gauge

Located in neck of fuel filler. Inspect for

debris. Remove and clean if necessary.

7.5 Coalescer Maintenance

Daily, check the oil level in the coalescer

sump. If the level has risen, check for water

contamination, drain off any water present

and top-up the oil to the level between the

marks on the dipstick. Water is removed by

means of the drain tap fitted to the side of

the coalescer sump.

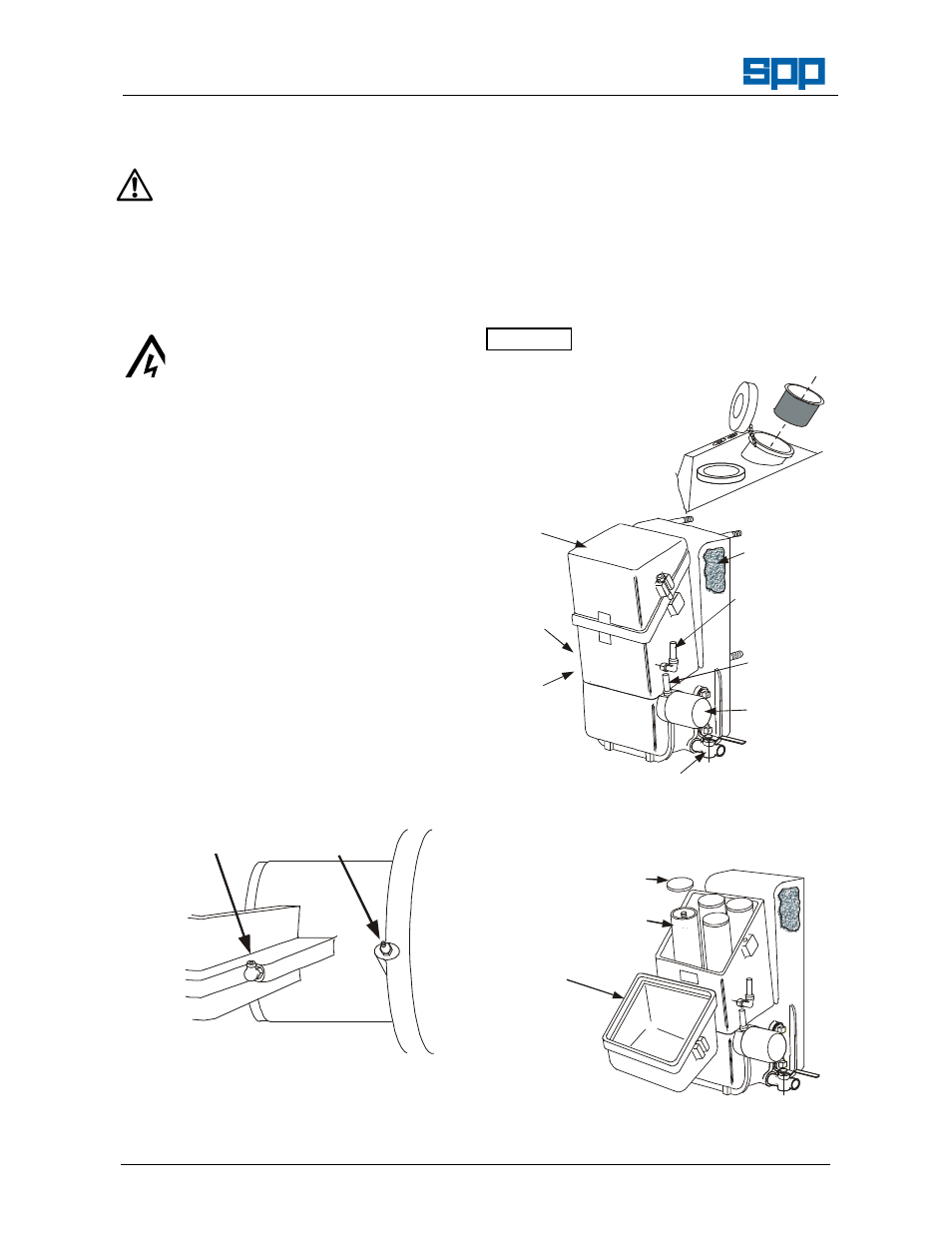

7.6 Coalescer Filter Element Replacement

Coalescer filter elements must be replaced

after the first 500 hours or one month of

operation of a new vacuum pump, after

which they need to be replaced only when

the

inside

surface

becomes

heavily

discoloured i.e. black or dark brown. These

elements cannot be cleaned, new elements

must be fitted when required thus:

NEWC

OAS3

REMOVE THE COALESCER LID

UNSCREW THE

ELEMENT CAPS

LIFT ELEMENTS

AND REPLACE

REPLACE THE

COALESCER

LID

Ensure that the seals at the top and bottom

of each filter element are fitted correctly.

ATTENTION

FU

EL

FI

LT

ER

NEWC

OAS1

OIL FILLER

& DIP STICK

EXHAUST

PORT

(FAR SIDE)

COALESCER

LID

WATER DRAIN TAP

FILTER

MESH

OIL

SCAVENGE

PIPE

OIL

FEED

PIPE

OIL

FILTER