Commissioning and operation – SPP Pumps Auto Prime - High Flow Range XF300 & 400 User Manual

Page 8

Manual No/Rev

W77-009E / 2

Operators Instructions for

XF300 & XF400 Range Centrifugal Pumps

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 8 of 23

clean to ensure that site debris is not drawn

into the pump when it is commissioned.

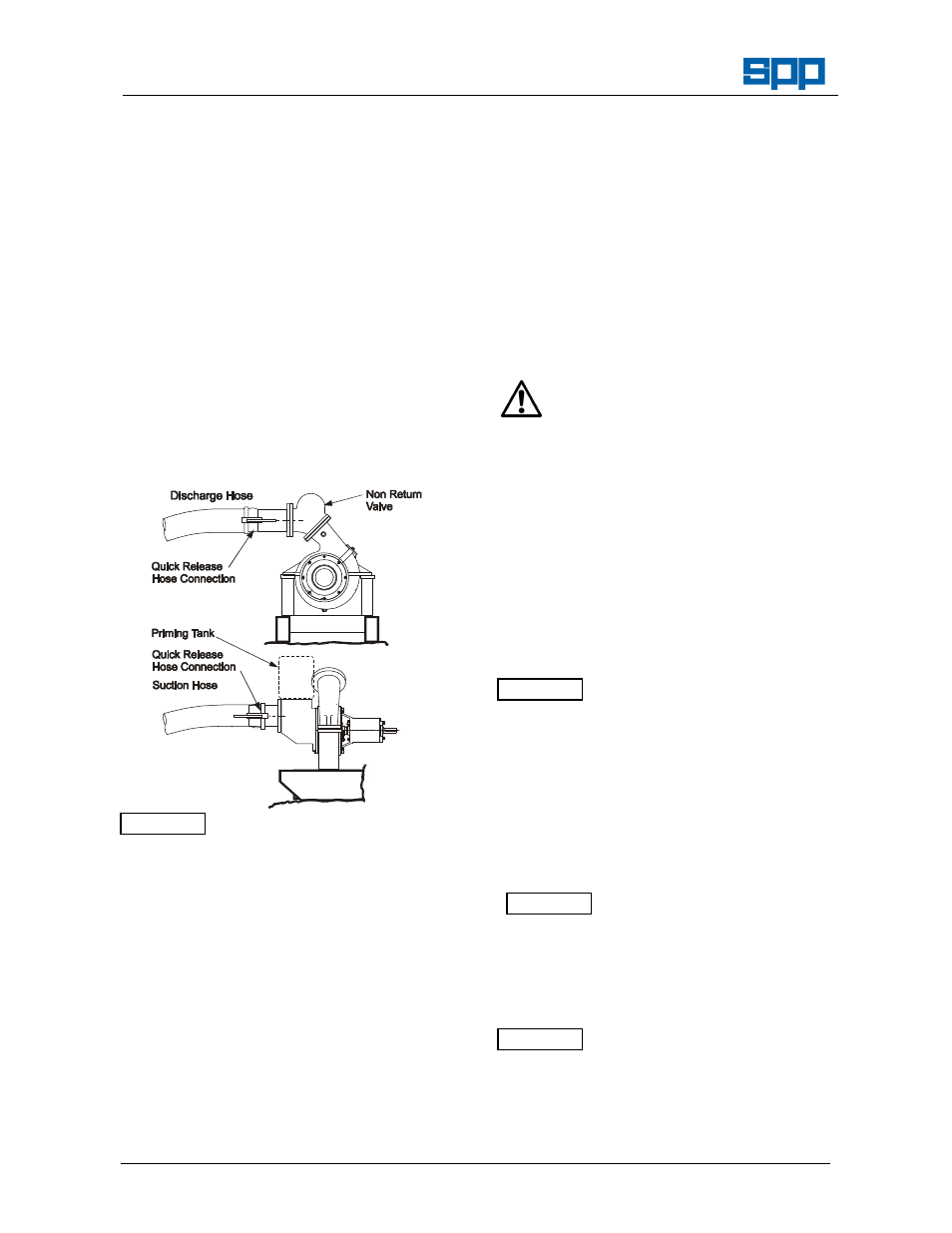

4.7 Discharge Pipework

Pipework should be as short and straight as

possible to reduce friction head loss.

A non-return valve is usually fitted to

prevent the pump from excessive back

pressure and reverse rotation and a

discharge valve must be fitted to regulate

the flow and allow for inspection and

maintenance on the pump.

The suction and discharge pipework must

be independently supported and positioned

such that no excessive forces and moments

are exerted on the pump flanges.

Typical Pipework

XFPIPE1.CDR

Failure to support suction and delivery

pipework may result in distortion of the

pump casing, with the possibility of early

pump failure.

4.8 Mechanical Seal Vent Pipe

The mechanical seal oil chamber is fitted

with a clear plastic vent pipe. This is to be

routed to a suitable drain point or into the

bund. It is important to be able to see any

fluid discharge from this pipe.

4.9 Baseplate and Foundations

The pump is designed to be secured to a

substantial baseplate to maintain the shaft

alignment between the driver and the pump.

The baseplate should be securely located

on level ground or mounted on foundations.

The shaft alignment should be checked

again before commissioning and putting the

pump into operation.

5. COMMISSIONING AND

OPERATION

Abrasion & Entrapment Hazard

Do NOT touch any moving or rotating parts.

Guards are provided to prevent access to

these parts, where they have been removed

for maintenance they MUST be replaced

before operating the equipment.

5.1 Commissioning Checks

These checks must be done after first

installation and after pump maintenance

that required removal of the rotating

assembly or draining of the bearing housing

and mechanical seal oil chambers.

Check the oil level in the mechanical seal oil

chamber sight glass.

Check the oil level in the bearing housing oil

chamber sight glass is at the level mark in

the centre of the glass.

Initial checks of oil level should be done

with the pump level to prevent misleading

readings.

The maximum inclination of the pump from

horizontal in any direction when running is 5

degrees

Refer to Section 6.4 - Bearing Lubrication.

Do not overfill the bearing and seal oil

chambers as this will cause overheating

and leakage.

ATTENTION

ATTENTION

ATTENTION

ATTENTION