Transport handling & storage instructions, General description – SPP Pumps Auto Prime - High Flow Range XF300 & 400 User Manual

Page 5

Operators Instructions for

XF300 & XF400 Range Centrifugal Pumps

Manual No/Rev

W77-009E / 2

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 5 of 23

This symbol gives warning of a hazard to

the pump itself, which in turn could cause a

risk to personal safety.

2. TRANSPORT HANDLING &

STORAGE INSTRUCTIONS

2.1 Transport

AUTOPRIME XF pumps are despatched

fully assembled and lubricated except for

overseas orders where the lubricating oil in

the seal and bearing housing is drained.

Pumps are protected against corrosion and

packed for transport by normal road, rail

and sea carriers.

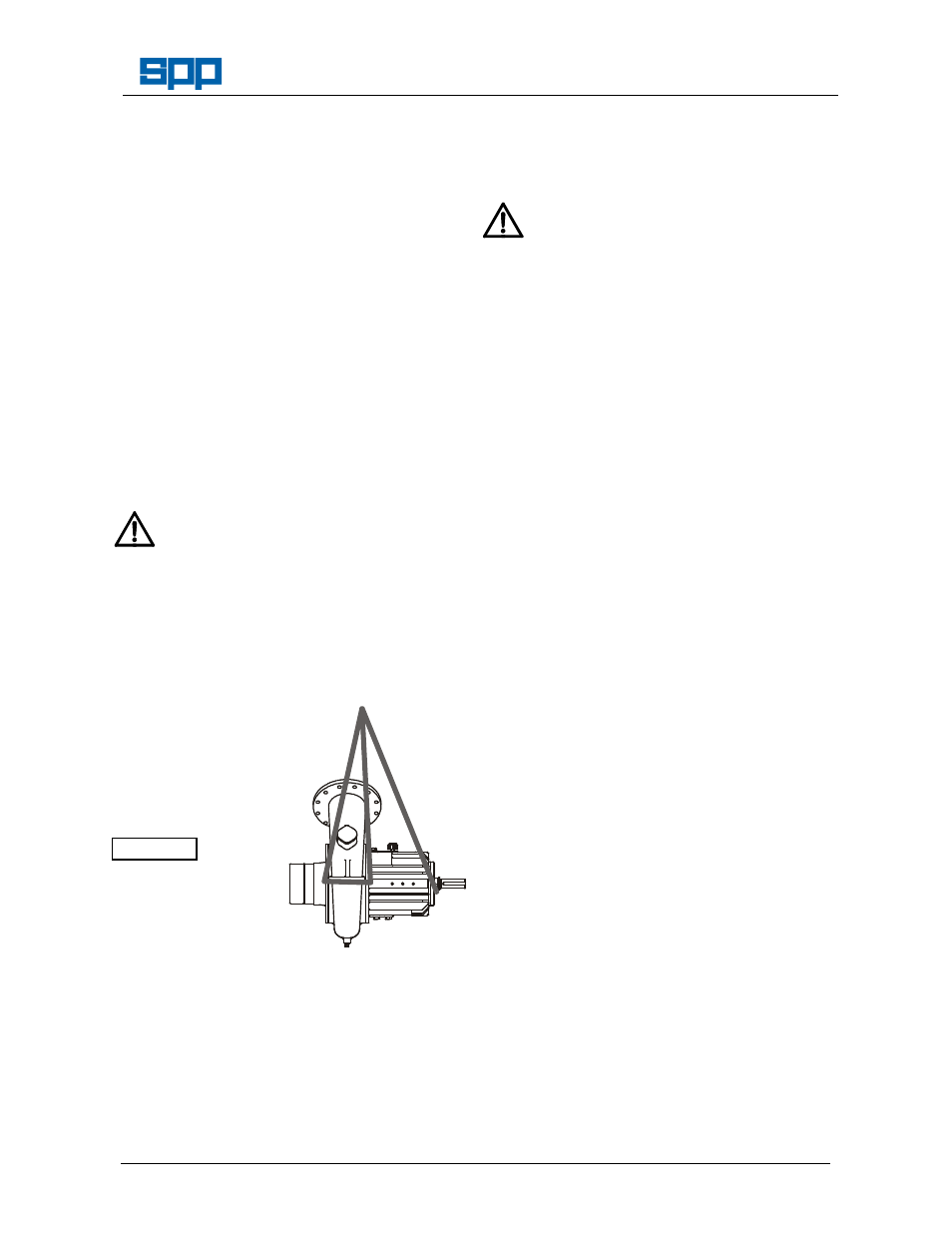

2.2 Handling

Crushing Hazard

When lifting the pump, use lifting equipment

having a safe working load rating suitable

for the weight specified. Use suitable slings

for lifting any pump not provided with lifting

points.

The use of suitable fork-lift truck and four

chain

crane

sling

equipment

is

recommended

but

locally

approved

equipment of suitable rating maybe used.

Pumps supplied

on pallets may

be lifted by fork

lift truck, to lift

from the pallet

the pump should

be

slung

as

shown.

It is important to

remove the fan

before lifting to

avoid damaging

the fan

Pump weight is shown in Section 8.

2.3

Storage

2.3.1

Temporary Storage for up to Six Weeks

If the pump unit is not to be used

immediately it should be stored carefully in

a horizontal position, in a sheltered, dry

location. Additional rust preventative should

be applied to all unpainted carbon steel or

cast iron parts, and should not be removed

until final installation.

2.3.2

Long Term Storage

Shearing Hazard

Do NOT place fingers or hands etc. into the

suction or discharge pipe outlets and do

NOT touch the impeller, if rotated this may

cause severe injury. To prevent ingress of

any objects, retain the protection covers or

packaging in place until removal is

necessary for installation. If the packaging

or suction and discharge covers are

removed for inspection purposes, replace

afterwards to protect the pump and

maintain safety.

Fill the seal and bearing housings with

recommended oil to ensure that the shaft,

seal and bearings remain rust free.

The pump shaft should be rotated by hand

at least five turns every six weeks.

For special protection of the coupling, diesel

engine

and

electric

motors,

where

applicable, refer to the manufacturers'

instructions. in the relevant appendix.

2.3.3

Exposed or Extreme Conditions Storage

For exposed storage or extreme variants in

atmospheric or environmental conditions,

please refer to SPP Pumps Ltd. for special

storage instructions to suit the conditions

applicable.

3. GENERAL DESCRIPTION

SPP Pumps’ AUTOPRIME XF Pumps are a

range of horizontal centrifugal pumps. The

two or three vane open impeller design will

handle dirty water, industrial effluents, and

sludge etc, including solids.

The mechanical assembly comprises a rigid

shaft, supported by oil lubricated bearings

with an open vane type impeller mounted in

a removable bearing housing assembly.

The bearing housing is air cooled by a fan

mounted on the shaft.

This is attached to an end suction volute

casing fitted with a front wear plate. The

bearing

housing,

shaft

and

impeller

assembly can be withdrawn from the volute

for maintenance without disconnection of

pipework or the driver provided that a

spacer coupling has been fitted.

ATTENTION