SPP Pumps Auto Prime - High Flow Range XF300 & 400 User Manual

Page 17

Operators Instructions for

XF300 & XF400 Range Centrifugal Pumps

Manual No/Rev

W77-009E / 2

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page

17

of 23

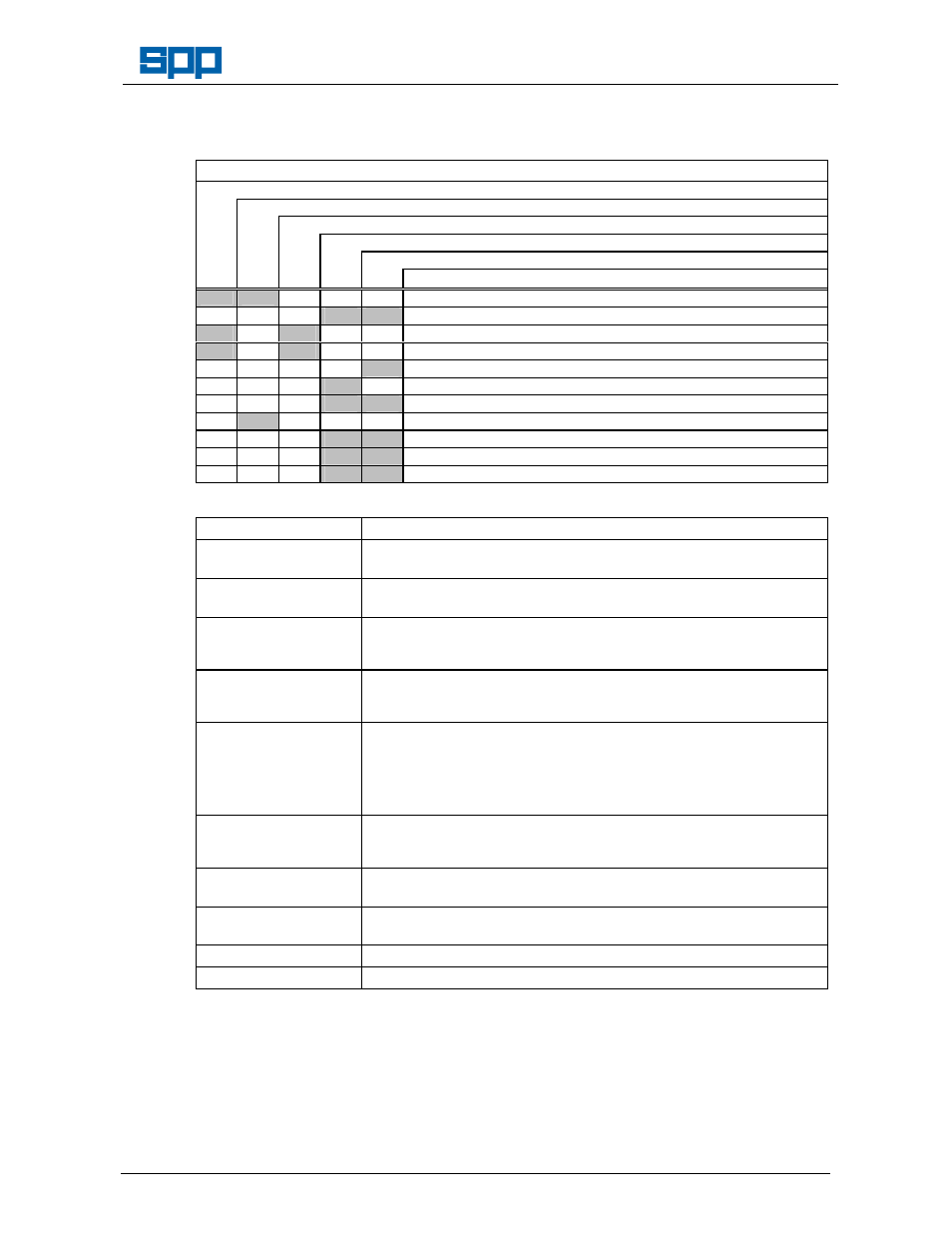

7.2 Pump Fault Finding

POTENTIAL FAULT OR DEFECT:

Insufficient liquid delivered.

Liquid delivered at low pressure (Fails to achieve the required delivery head)

Loss of liquid after starting.

Excessive vibration.

Pump bearings run hotter than normal.

PROBABLE CAUSES

Speed too low.

Speed too high.

Blockage or Internal collapse of suction or delivery hose

Air leaking into pump casing or priming system.

Lubricating oil dirty or contaminated.

Foundation not rigid or pump mountings loose or worn.

Misalignment of pump and driver.

Impeller worn or increased clearances

Bearing worn.

Rotor out of balance due to blockage or damage.

Shaft bent.

CAUSE

REMEDIAL ACTION

Speed too low.

Check that the driver is functioning correctly and running at the

required speed.

Speed too high.

Check that the driver is functioning correctly and running at the

required speed.

Blockage or Internal

collapse of suction or

delivery hose

Check hoses, replace damaged hoses or clear blockage.

Air leaking into pump

casing or priming

system.

Check all hose joints, plugs and pipes.

Check that the vacuum pressure seal is not leaking.

Bearing lubricating oil

dirty or contaminated.

Drain the oil, check type of contaminant, if no metal pieces are

present, flush the bearing housing and refill with new oil. Run the

pump and monitor bearing noise and temperature.

If metal pieces are present check for shaft movement and if excessive

dismantle the pump and replace the pump bearings.

Foundation not rigid or

pump mountings loose

or worn.

Ensure that the pump driver mounting bolts are tight and the pump

foundations are secure.

Misalignment of pump

and driver.

Check and realign the pump and driver as specified.

Bearings worn.

Remove the bearings, clean and inspect for damage and wear,

replace as necessary.

Rotor out of balance.

Check the impeller for damage, replace as necessary.

Shaft bent.

Check shaft run-out and replace if needed.