SPP Pumps Auto Prime - High Flow Range XF300 & 400 User Manual

Page 7

Operators Instructions for

XF300 & XF400 Range Centrifugal Pumps

Manual No/Rev

W77-009E / 2

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 7 of 23

4.4 Pump Installation

It is recommended that the pump unit is

fitted to the baseplate before fitting the

motor and coupling. The distance between

shaft ends should be established to suit the

coupling by reference to the manufacturer's

instructions.

4.5 Shaft Alignment

To minimise the side load on the bearings

and to achieve full coupling and bearing life,

it is recommended that the shafts are

aligned as accurately as possible i.e. well

below the allowable misalignment of the

coupling.

Refer

to

the

coupling

manufacturer's instructions or proceed

generally thus:

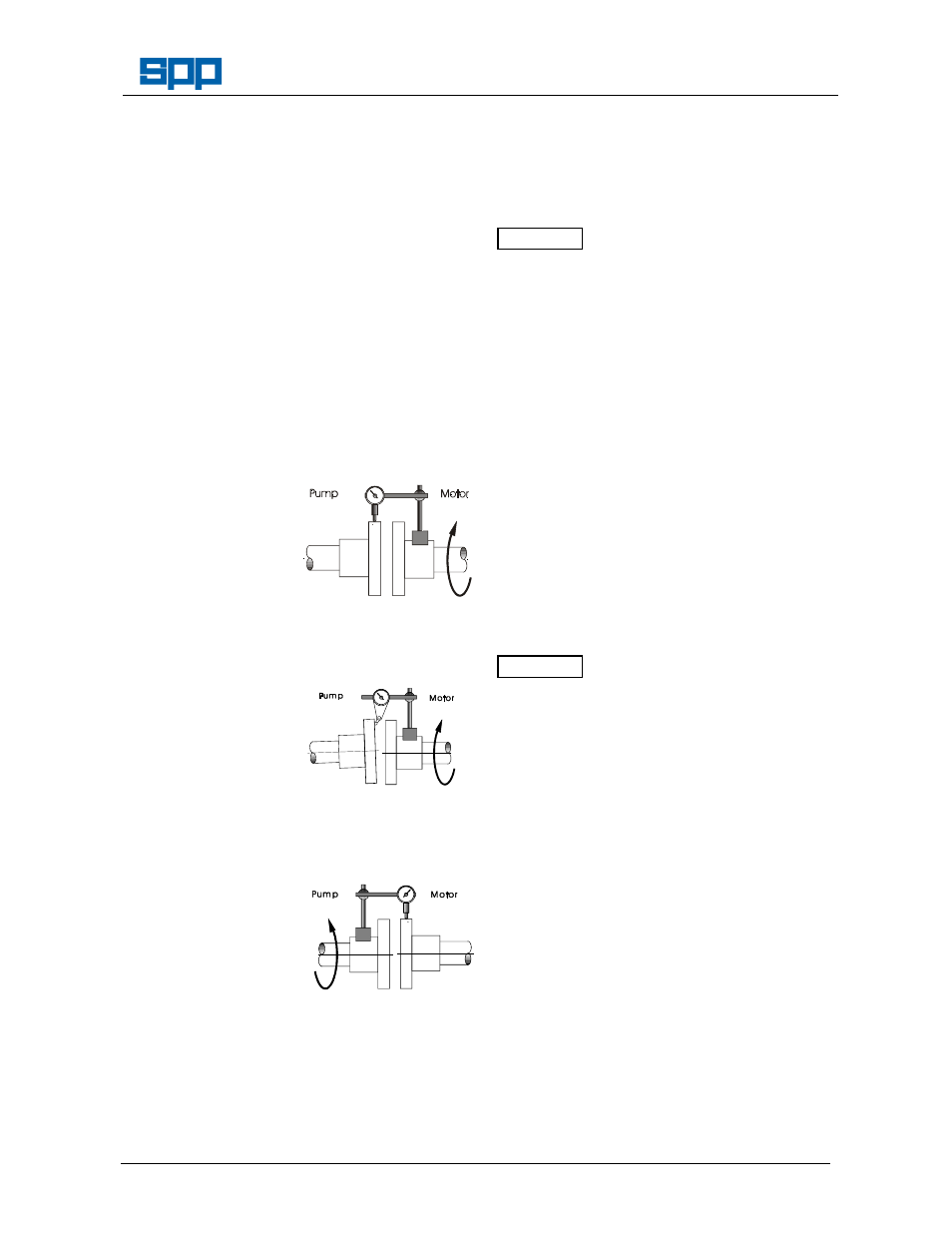

a)

Lateral Alignment

Mount a dial gauge

on the motor shaft

or coupling with the

gauge running on

the outer machined

diameter

of the

pump coupling. Turn the motor shaft and

note the total indicator reading.

b)

Angular Alignment

Mount a dial gauge

on the motor shaft

or coupling to run

on a face of the

pump coupling as

near the outside

diameter

as

possible. Turn the

motor shaft and note the total indicator

reading.

c)

Confirm Lateral Alignment

Mount

the

dial

gauge on the pump

shaft or coupling

with

the

gauge

running

on

the

outer,

machined

diameter

of

the

motor

coupling.

Turn the pump shaft and note the total

indicator reading.

d)

Adjustment

The motor must be shimmed and re-

positioned to align the shafts within the

coupling manufacturer's specifications.

e)

Alternative Method

If a dial gauge is not available, callipers or

taper gauge may be used to measure the

distance between the coupling flanges at

four points around the circumference and a

straight edge used to check the lateral

alignment of the outer flange diameters.

Shaft alignment must be checked again

after the final positioning of the pump unit

and connection to pipework as this may

have disturbed the pump or motor mounting

positions.

4.6 Suction Pipework

It is recommended that the pump is

installed as near to the liquid source as

possible

Any rigid pipework should be supported

independently and close to the pump so

that no strain is transmitted to the pump

when the flange bolts are tightened. Use

pipe supports at intervals necessary to

provide support. When expansion joints are

used in the piping system, they must be

installed beyond the piping supports closest

to the pump.

Collapsible hoses must not be used on

the suction side of the pump.

Install piping as straight as possible,

avoiding unnecessary bends. Where

necessary use long sweep 90

°

bends or

fittings to decrease friction losses.

Make sure that all suction piping joints are

air tight. Provide pipe expansions when hot

fluids are to be pumped. Where reducers

are used, eccentric reducers (tapered side

down) are to be fitted in horizontal suction

lines and straight taper reducers in vertical

discharge lines. Undulations in the pipe

runs or misuse of reducers may cause the

formation of air pockets in the pipe and thus

prevent the efficient operation of the pump.

The suction (and discharge) pipes can be

one or two sizes larger than the pump

flange connections. A horizontal suction line

should have a gradual rise to the pump.

A correctly sized filter or strainer must be

fitted to hold back larger items.

The suction pipe work should be flushed

ATTENTION

ATTENTION