SPP Pumps Auto Prime - High Flow Range XF300 & 400 User Manual

Page 11

Operators Instructions for

XF300 & XF400 Range Centrifugal Pumps

Manual No/Rev

W77-009E / 2

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 11 of 23

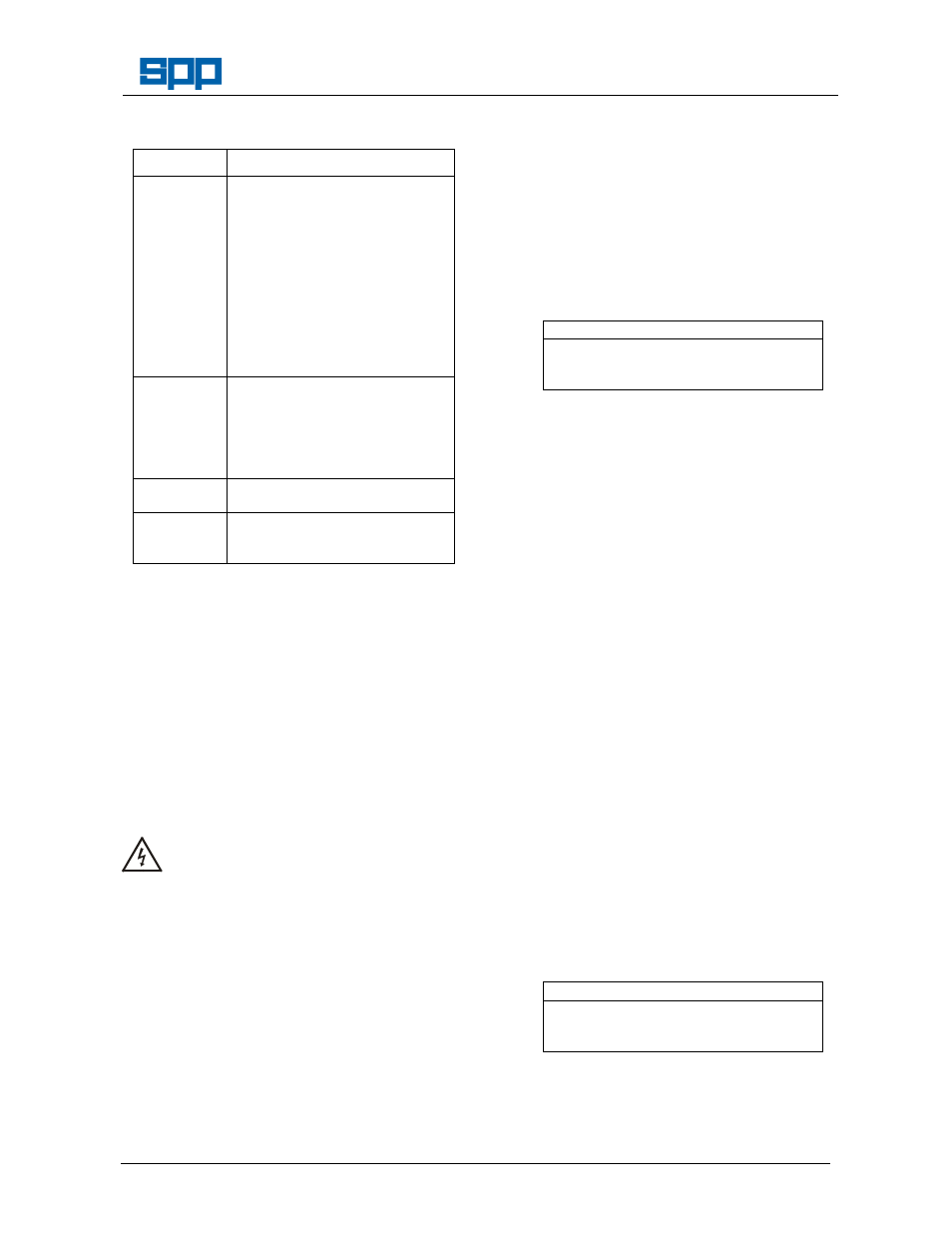

Recommended Maintenance Schedule

PERIOD

TASK

Daily (with

the pump

running)

Check the bearing lubricating oil

level in the bearing housing

running sight glass and top up

oil if needed with 0.1 litres of oil.

Check the mechanical seal

lubrication oil level and top up if

required.

Check the bearing housing

temperature does not exceed

80degC.

Check visually for leaks.

Check for vibration.

Weekly or

170 hours (

with the

pump not

running)

Check security of all fasteners

and hose fittings.

Check bearing oil level in the fill

level sight glass.

Check and clean the magnetic

drain plug.

4 monthly or

2500 hours

Replace the bearing and

mechanical seal lubrication oil.

Annually or

8000 hours

Replace the bearings, the drive

end lipseal and the mechanical

seal.

The above schedule is given for guidance

but site operating conditions may override

the

suggested

maintenance

intervals.

Adjustments to time scales will also have to

be made if the pump is idle for long periods.

For motor or engine maintenance and

maintenance of the priming system (when

fitted) refer to the separate operators

handbooks included within the pump

documentation pack.

6.2 Preparation for Maintenance

Electric Shock & Accidental Starting

Hazard

ISOLATE the equipment before any

maintenance work is done. Switch off the

mains supply, remove fuses, apply lock-

outs where applicable and affix suitable

isolation

warning

signs

to

prevent

inadvertent re-connection.

For diesel driven pumps disconnect the

negative battery lead to prevent inadvertent

starting.

In order to avoid the possibility of

maintenance personnel inhaling dangerous

fumes or vapours. It is recommended that

maintenance work be carried out away from

the pump location by removal of the bearing

housing and shaft assembly to a suitable

maintenance area.

It is important to ensure the suitable lifting

equipment is available and that the work is

carried out in a clean area.

6.3 Maintenance of the Mechanical Seal

The

mechanical

seal

requires

no

maintenance or adjustment when running.

Mechanical Seal Oil

Texaco Rando HD10 mineral oil

without EP additives.

Approx 7 litres for a complete fill.

6.4 Bearing Lubrication

a)

The pump incorporates a combination of

spherical roller and angular contact ball

bearings, lubricated by mineral oil that is

circulated by a flinger, to a gallery, and then

fed to the bearings.

b)

Bearing oil sump should be filled to the

centre of the sight glass when the pump is

cold and level. When running an oil level

should become visible in the gallery sight

glass after no more than three minutes, if it

does not then the sump oil level is too low

for the flinger to pick up. After the first run

the pump should be allowed to cool and the

level re-checked, a small amount of

additional oil may be required to replace the

oil retained in the gallery and bearings.

After first 50 hours drain off a sample and

check oil for contamination, change if

contamination is found.

c)

Frequency of re-lubrication is dependant on

a number of factors, which can vary with the

application.

These

include:

operating

conditions, frequency and duration of

service, environment (humidity, dust & other

contaminants) and operating temperature.

The frequency of re-lubrication listed below

is therefore for guidance only and should be

modified to suit operating conditions.

Bearing Lubricating Oil

Texaco Rando HD68 mineral oil

without EP additives.

Approx 4 litres for a complete fill.