Pump maintenance chart – SPP Pumps Auto Prime Medium Head Open Set - AC & AL Range User Manual

Page 9

Operators Handbook for

Diesel Driven Pump Sets

Manual No/Rev

W72-002E / 11

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 9 of

16

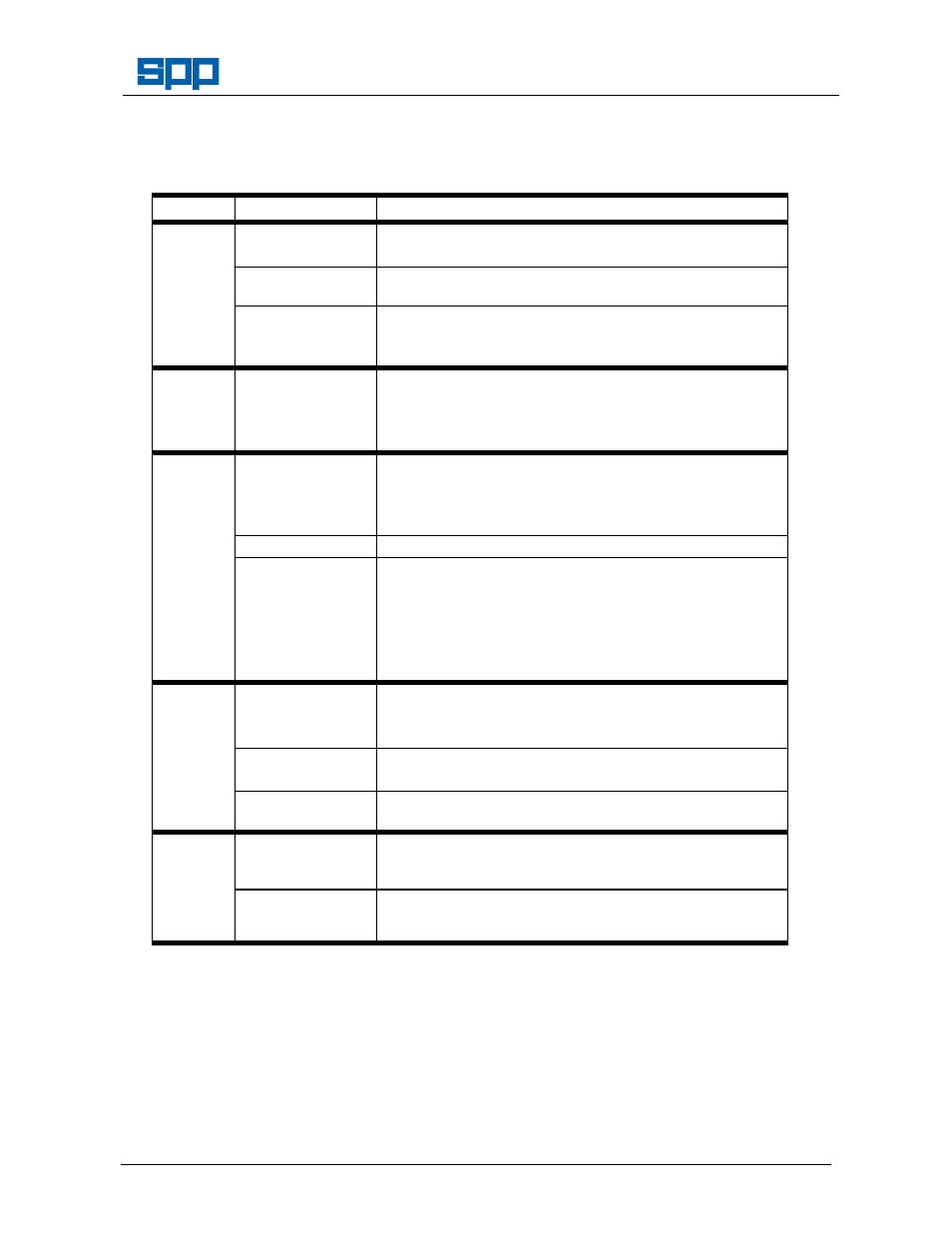

6. PUMP MAINTENANCE CHART

For engine maintenance periods refer to the engine operators handbook at the back of this publication.

PERIOD

PUMP SET

TASK

Daily

All units

Visually check for leaks

Check for vibration

Mechanical seal

units

Check mechanical seal coolant/lubricant level and top up as

required

100M,

150, 150M,

& 200

Drain any water from coalescer, check oil level and top up as

required

Hand test bearing housing for any sign of temperature rise

Weekly or

100 hrs

All units

Check all fastener security

Check the condition of the lifter bracket/frame and check the

security of attachment to the unit

Check tension of vacuum pump drive belt

Monthly

or 500

hrs

AC50 & AC75

Check oil level of suction line reservoir

Remove primary tank assembly and check pump internals

for wear

Check valve gear - clean or renew filter element

AC80 & AC100

Check oil level of vacuum pump reservoir

100M,

150, 150M,

& 200

Change coalescer sump oil

Clean coalescer sump oil filter mesh

Remove front cover and check pump internals for wear

Check valve gear - clean or renew standard filter element.

Check high capacity filter element.

Grease bearings

6 monthly

or 1500

hrs

All units

Check reflux ball is sealing on its seat

Check and if necessary renew vacuum pump drive belt

Dismantle and clean valve gear, tank and connecting pipes

Vacuum pressure

seal units

Dismantle and clean pump vacuum pressure seal

Renew packing

Mechanical seal

units

Change mechanical seal coolant/lubricant

Annually

or 6000

hrs

All units

Check vacuum pump blade condition

100M,

150, 150M,

& 200

Check bearing condition

Renew coalescer filter mesh

The above schedule is given for guidance but site operating conditions may override the suggested

maintenance intervals.