Maintenance instructions – SPP Pumps Auto Prime Medium Head Open Set - AC & AL Range User Manual

Page 10

Manual No/Rev

W72-002 / 11

Operators Handbook for

Diesel Driven Pump Sets

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 10 of

16

1.

7. MAINTENANCE INSTRUCTIONS

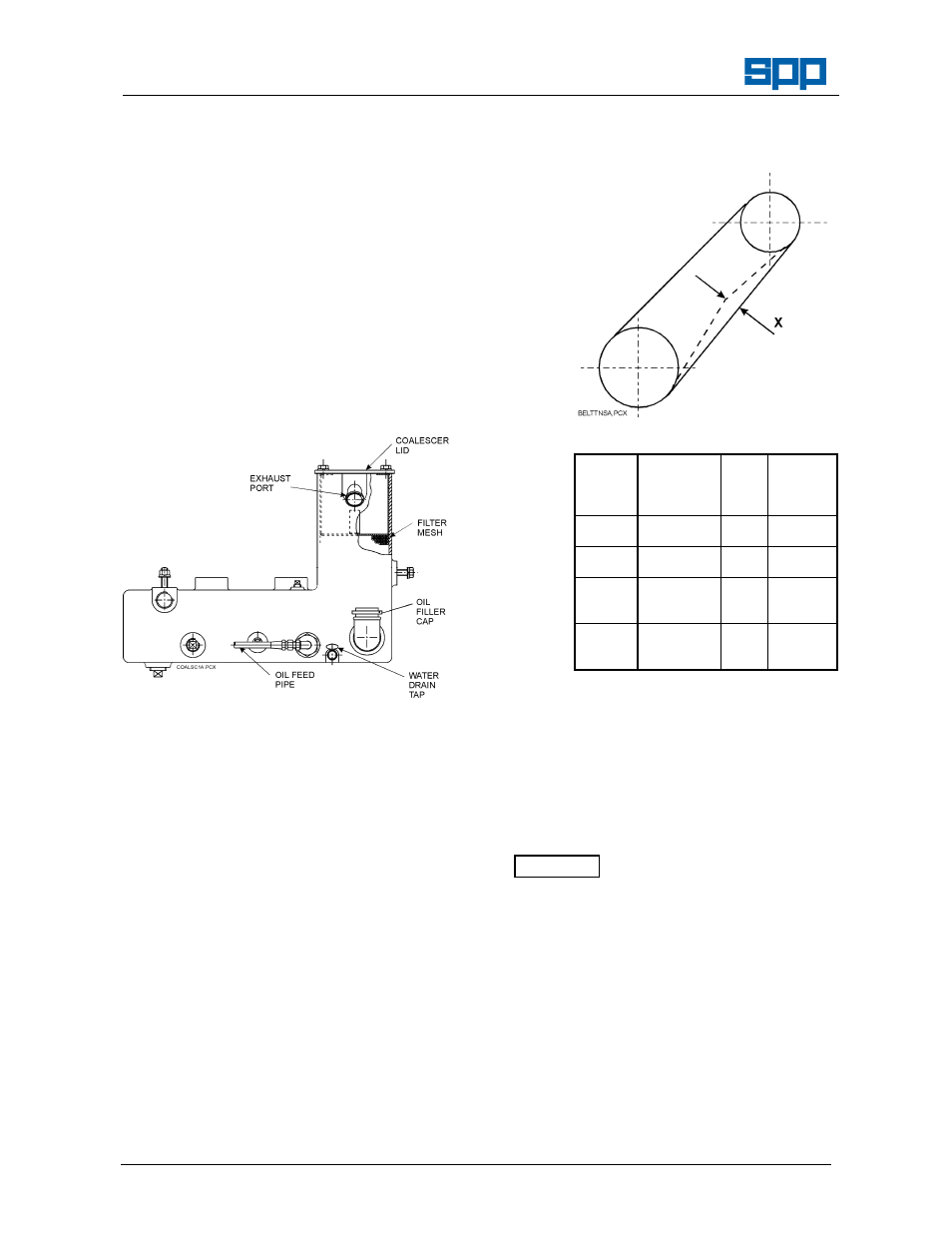

7.1 COALESCER (100M, 150, 150M, & 200)

Check the oil level in the coalescer tank and

drain any water daily. The top of the oil

should be level with the underside of the filler

cap. Water is removed by means of the drain

tap fitted to the side of the coalescer sump.

The filter mesh is accessed by removing the

coalescer lid and must be cleaned regularly

by washing in petrol or a similar spirit. When

refitting ensure filter mesh is below exhaust

port. The oil feed pipe should be cleaned in a

similar manner and blown through with an air

line.

Figure 0-1 Coalescer detail

7.2 OIL RESERVOIR (AC50, AC75, AC80 &

AC100)

7.2.1 AC57 &AC75

Ensure that oil reservoir is always kept

topped up.

7.2.2 AC80 & AC100

Maintain the oil level between the

maximum and minimum levels marked

on the bottle.

7.3 COUPLING (open coupled sets)

Coupling details are provided at the back of

this manual.

7.4 DRIVE BELT ADJUSTMENT

Figure 0-2 Belt tensioning

Pump

sets

Belt type

Deflec-

tion

‘X’mm

Force (kg)

producing

deflection

‘X’)

AC50 &

AC75

V belt

5

1.5

AC80 &

AC100

V-belt

4

1.5

Others Timing

(toothed)

belt

4

1.5

Canopied

Low noise

units

PowerTwist

A section

link belt

1.6

1.5-2.0

To adjust belt tension, loosen the vacuum

pump holding nuts and slide the

vacuum pump outward. When the

correct belt tension is obtained re-

tighten holding nuts. Ensure that the

pump drive is in line after tightening.

Link belt drives can be further adjusted by

removing links.

DO NOT OVERTIGHTEN BELTS UNDER

ANY CIRCUMSTANCES.

For AC50, AC75, AC80 & AC100 pumps

fitted with V belts and other pumps

fitted with PowerTwist link belts, the

belts can be replaced by slackening the

vacuum pump holding down bolts. For

other pumps it is necessary to

disconnect the coupling to replace the

belts.

7.5

ATTENTION