SPP Pumps Auto Prime Medium Head Open Set - AC & AL Range User Manual

Page 12

Manual No/Rev

W72-002 / 11

Operators Handbook for

Diesel Driven Pump Sets

Our policy is one of continuous improvement and we reserve the right to alter specifications at any time

Page 12 of

16

5.

Slide the seal assembly back along the

shaft to locate on backplate. Tighten

securing nuts and screws evenly.

6.

Refit the shaft guard.

7.6

MECHANICAL SEALS

1.

Ensure that the coolant/lubricant level is

maintained. It is imperative that the seals are

never run dry. Immediate seal failure will

result.

2.

Any contamination of the fluid should be

investigated immediately. Should a large loss

of fluid be experienced then the pump must

be stopped immediately.

3.

Replacement of the seals is considered a

workshop operation where higher standards

of cleanliness can be maintained and the

specialised tooling required is more readily

available.

7.7 NON-RETURN VALVE

1. A ball type non return valve is fitted to the

pump discharge.

2. The ball should be regularly checked for

freedom of movement and absence of debris

by inspection through the discharge.

3. On larger pumps the correct seating of the ball

can be checked through the delivery flange of

the valve body. The valve body should be

removed to check the seat for damage or

wear.

7.8 PUMP BEARINGS (Open coupled pump sets

only)

1. The pump ends employ grease lubricated

bearings which will give long service life

provided they are:-

a)

Correctly lubricated at regular intervals

b)

Cleaned and, if removed, refitted with

care

c)

Serviced with clean tools and in a clean

area.

2. The early stages of bearing failure can be

detected by noting either unusual vibration,

bearing housing temperature rise or unduly

noisy operation. If any of these signs be

exhibited, the pump should be stopped and

the cause investigated.

3. Greased bearings are pre-packed with

lubricant during pump manufacture. Shrinkage

and normal loss of grease necessitates re-

lubrication at regular intervals. These

intervals will largely be determined by

site conditions. The recommendations

given in Table 1 are therefore for

guidance only.

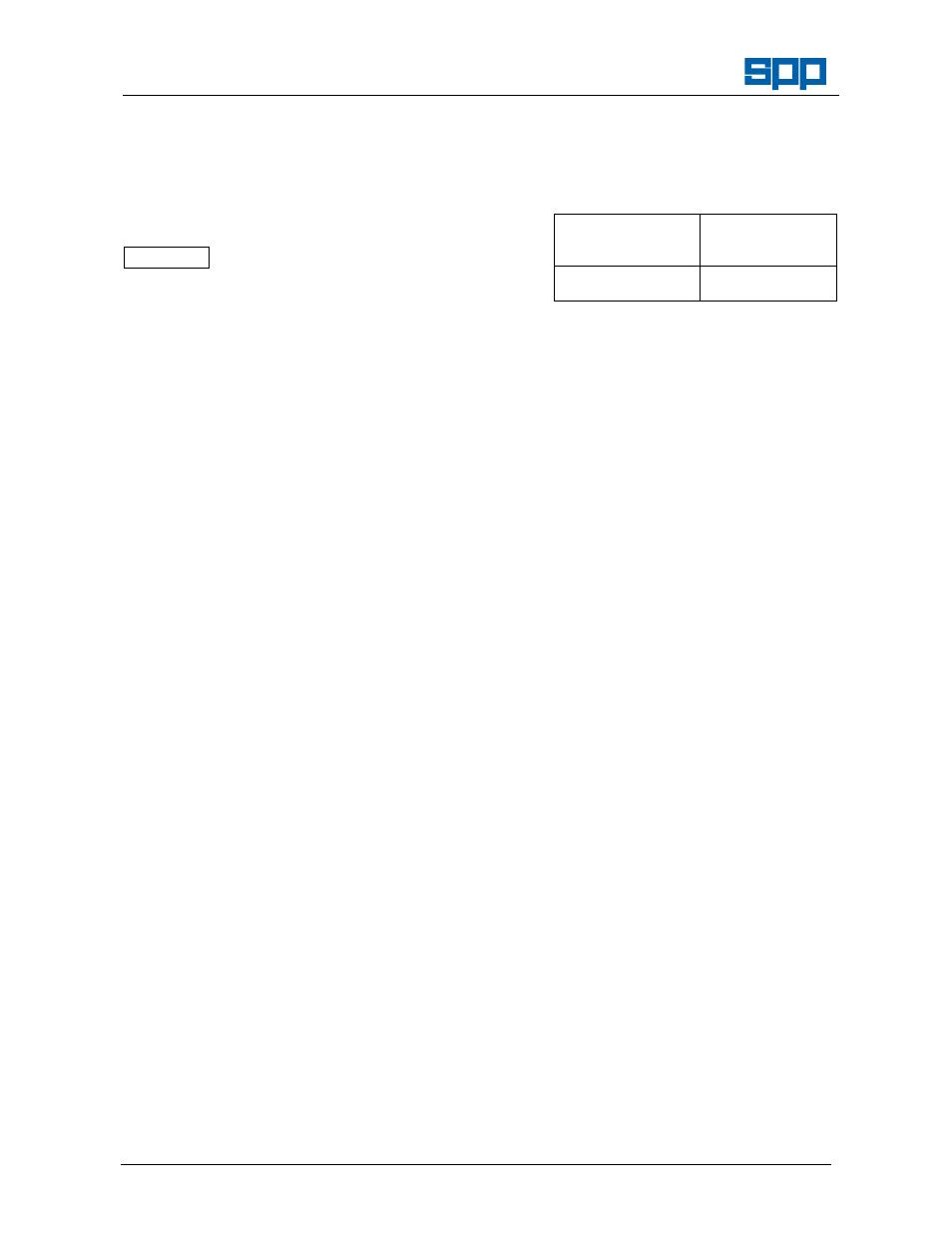

Radial Bearing

Non drive end

(NDE)

Radial & Thrust

Bearing

Drive end (DE)

4 months

3000 hrs

4 weeks

750 hrs

Table 1 Guidance Intervals for bearing re-

greasing

4. The table is based on running speeds

of 1450rpm with a bearing temperature

not exceeding 70°C. Reduce the

interval by half for every 15°C above

70°C.

5. Clean both the grease fittings and

grease gun nozzle before use. For a

hand grease gun apply 2 or 3 strokes

to each nipple.

6. Overfilling can be as harmful to

bearings

as

under-lubrication.

Compaction of grease leads to it being

churned by the rolling action of the

bearings. This leads to overheating,

breakdown of the lubricant and bearing

failure.

7. Immediately after re-lubrication it is

normal for the temperature of the

bearing housing to rise in service. The

temperature should soon drop to

normal after a short period of running.

If the temperature remains elevated or

continues to rise, temporarily remove

the grease nipples and allow any

excess grease to escape.

7.9 VACUUM PUMP

Vacuum pump overhaul is beyond the

scope of this manual. Should the

vacuum pump be suspect then it is

recommended that an exchange unit is

fitted and the suspect unit returned for

examination.

7.10 VACUUM PUMP AIR FILTER

7.10.1 Standard air filter

Standard air filters are located in the

valve cover of the primary tank and

should be checked regularly for

cleanliness, distortion or damage (see

ATTENTION