Installation, Utilities, The gas supply – Fulton Vertical Coil (FT-C_S) Thermal Fluid (hot oil) Heater User Manual

Page 13

Questions? Call (315) 298-5121, or visit us online at www.fulton.com

SECTION 2

FTCS-IOM-2013-1114

INSTALLATION

2-7

combustion or nuisance failures.

TABLE 5- MINIMUM MAKE-UP AIR REQUIREMENTS AND

RECOMMENDED AREA OF OPENING FOR VENTS

Model

Minimum

Make-Up

Air (SCFM)*

Opening Area

(in2)**Lower

Vent

Opening

Area (in2)

Upper Vent

FT-0080C

200

400

135

FT-0120C

300

600

205

FT-0160C

400

800

270

FT-0240C

600

1200

400

FT-0320C

800

1600

535

FT-0400C

1000

2000

670

FT-0600C

1500

3000

1000

FT-0800C

2000

4000

1335

FT-1000C

2500

5000

1670

FT-1200C

3000

6000

2000

FT-1400C

3500

7000

2335

FT-0400S

1000

2000

670

FT-0600S

1500

3000

1000

FT-0800S

2500

4000

1335

*Minimum make-up air requirements are based on 25% excess air at high fi re.

**Opening areas are calculated based input of a single heater and do not account

for the ventilation needs of the equipment room. These measurements are

subject to state and local regulations.

NOTE:

A properly designed make-up air system in the

equipment room will preclude these possibilities and is

required to maintain proper combustion.

7. Eliminate potential for high risk situations for particulate

matter to be in the combustion air supply (e.g., as a

result of construction and maintenance activities).

Utilities

The Gas Supply

Adhere to the following for gas supply installation:

1. Install gas piping in accordance with all applicable

codes.

2. Ensure pipe and fi ttings used are new and free of dirt or

other deposits.

3. Ensure piping is of the proper size for adequate gas

supply to the gas head assembly. Consult your gas

company for specifi c recommendations.

4. When making gas piping joints, use a sealing

compound resistant to the action of liquefi ed

petroleum gases. Do not use Tefl on tape on gas line

heads.

5. Ensure no piping stresses are transmitted to the

equipment. The equipment shall not be used as a pipe

anchor.

6. Ensure all vent connections on diaphragms, gas valves,

pressure regulators, and pressure switches (gas-fi red

units) are vented per local code.

7. On

gas-fi red units with NFPA valve trains, ensure the

vent valve is piped to atmosphere per local code. See

Figure 4.

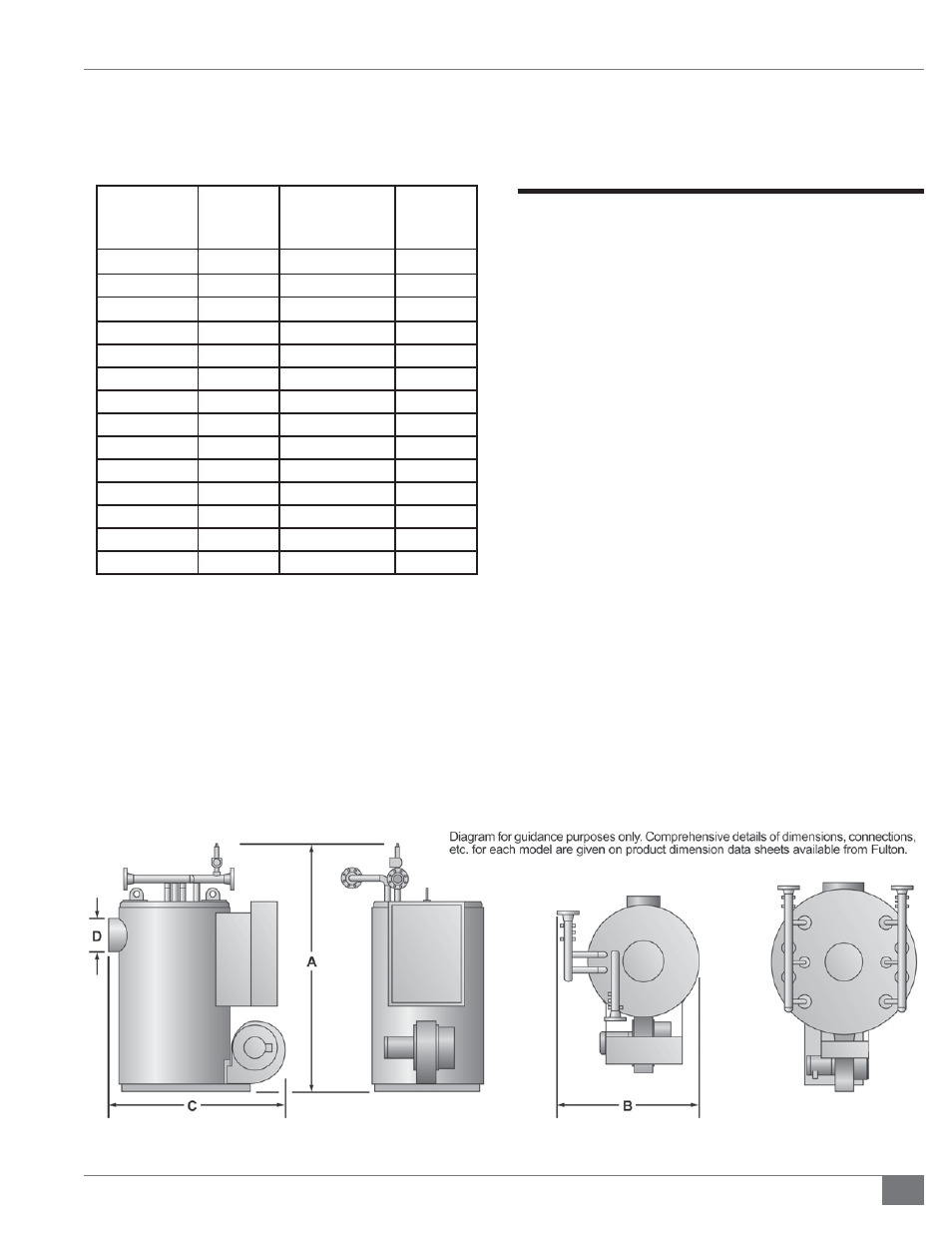

FIGURE 2 - DIMENSIONS (REFER TO TABLE 2)