Installation, Install control panel and wiring – Poweramp POWERSTOP SERIES User Manual

Page 16

14

4111-0014 — July 2013

INSTALLATION

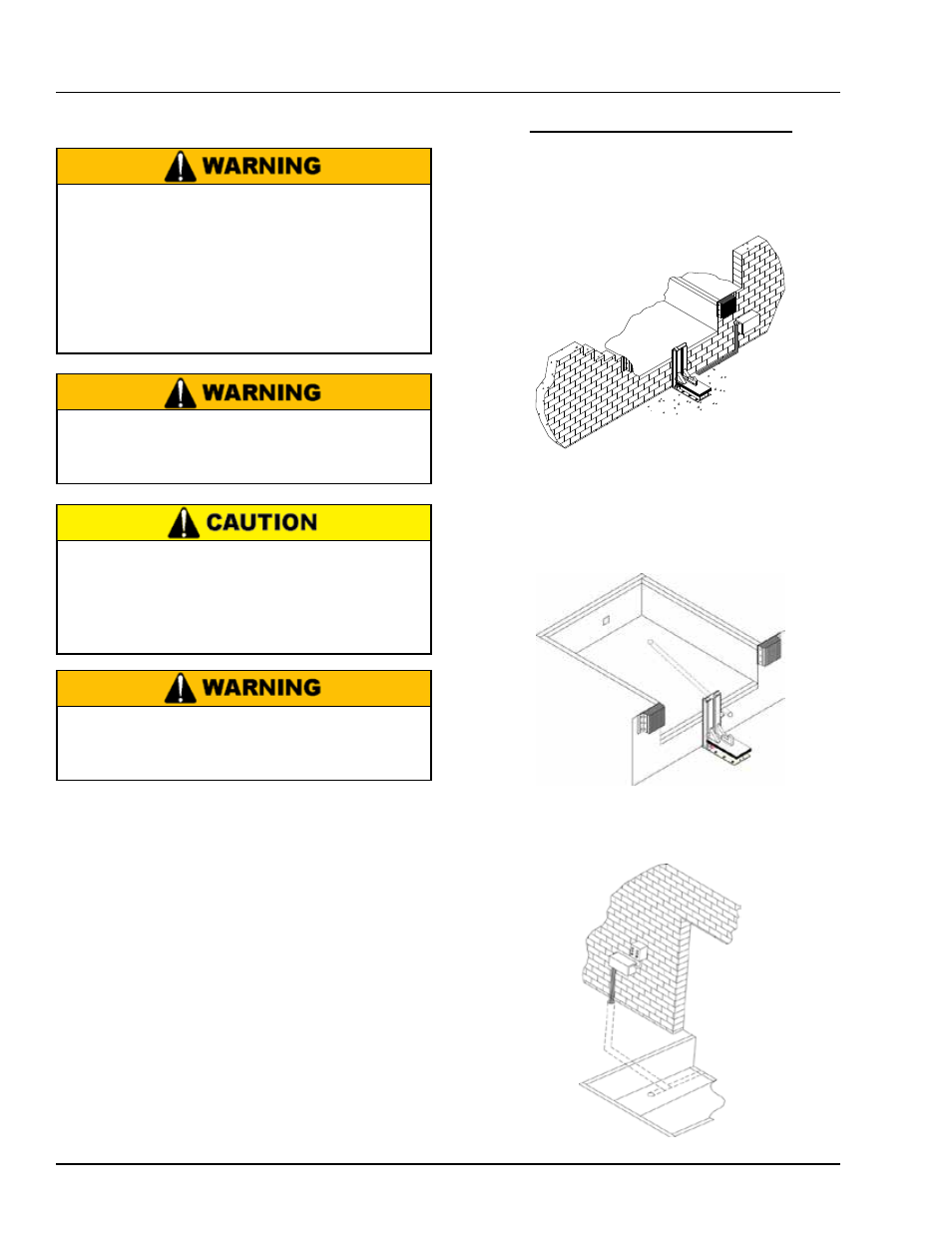

1. Mount the push button control panel (B) so bottom

of control panel-to-dock floor distance (C) is 48 in.

(1219.2 mm).

2. Install electrical disconnect panel (A) if not already

installed. (Provided by others)

3. Install and connect the control wiring to the face

of the building as shown in installation.

4. Connect the dock leveler power cable to the field

wires in the pit junction box. Refer to the electrical

drawings supplied with the dock leveler.

5. After all electrical connections in the vehicle

restraint have been made, test the vehicle restraint

function by following the instructions in the “Put New

PowerStop Restraint Into Service” section on next

page.

Install Control Panel and Wiring

IO ST

-A 11/06

LEVEL

11”

SECTION "A-A"

A

A

7

12

8

9

14

14

6

5

4

1

3

11

10

CONNECT TO BASE END OF RELEASE CYL.

BC

DESCRIPTION

NOTE

RC

CONNECT TO ROD END OF RELEASE CYL.

Capacitor Wiring Detail

M

ot

or

Bl

ue

M

ot

or

Re

d

6

2

13

R.V. SET @

HYDRAULIC SCHEMATIC

105

M

650 PSI

RC

BC

1

1

1431-0011

Connector - 2-Screw

3/8

2

3

1431-0086

Insulated Terminial

16-14 AWG

3

2

2101-0017

Hex Head Capscrew

3/8-16 UNC X 1

4

2

2101-0140

Lock Washer

3/8

5

1

2751-0016

Cover - J-Box

4 X 4

6

1

3051-0058

Capacitor - Motor Start

64-77mF - 330V

7

2

6431-0001

Grommet

1-3/8 OD X 3/4 ID

8

2

9301-0164

Fitting Conn Str Thrd

#4 ORB X #4 JIC

9

1

9391-0009

Powerpac - PowerStop

1PH - 115V - 1/4 HP - 1 GPM

10

1

9392-0045

Cover - PowerStop

B CAD

11

1

9393-0025

Powerpac Mounting Weldment

B CAD

12

2

9904-0097

Hyd Hose Assy - 1/4"100R1 X 24.00

#4 JICF SWIVEL BOTH ENDS

13

1

R513-0050

Wire

16 GA RED X 5.00"

14

2

R598-0090

Split Flex Conduit

1/4" X 9.00"

BILL OF MATERIAL

QTY

ITEM

DESCRIPTION

PART NO.

SIZE

STOP-TITE Overview

STOP-TITE Powerpack

Powerpack

Location Options

For comprehensive installation

instructions of the Automatic

STOP-TITE (STOP-TITE ) read and

understand the Installation

and Operation Manual.

AAL

McGuire.

McGuire

STOP-TITE

STOP-TITE

Coordinate powerpack location and hose

length for proper placement.

Dock Face

Appropriate location when the likelihood of

flooding, snow removal and damage from

trailer/trucks is minimal.

Under The Dock Leveler

When under the dock location is used, make

certain to locate the powerpack where leveler

will not interfere in below dock conditions.

The routing of hydraulic and electrical lines

from the powerpack to the restraint are

best placed through min. 3” PVC (hydraulic)

and 3/4” conduit (electricl) chase during pit

construction.

Inside Building

Locate powerpck to minimize obstruction

potential. Hydraulic and electrical lines

from the Powerpack to the restraint are best

placed through min. 3” PVC (hydraulic) and

3/4” (electrical) chase during pit construction.

AAL

Conduit, flexible or rigid, must be connected between the limit switch on the restraint and the powerpack. Wiring to and

from the restraint must be limited to restraint wires only. Do not run high voltage lines through the same conduit as restraint

wires. Conduit and associated hardware to complete wiring and mounting of powerpack are to be supplied by others.

POWERSTOP Overview

The electrical power must be OFF prior to electrical

installation. For maximum protection, use an OSHA

approved locking device to lock out all power

sources. Only the person installing the equipment

should have the key to unlock the power source.

Failure to follow these instructions may result in

serious personal injury or death.

DO NOT make any final electrical connections until

all welding has been completed. Failure to do this

may result in serious personal injury or death.

If dock leveler is present. Always stand clear of

platform lip when working in front of the dock

leveler. Serious personal injury or death may result.

All electrical work — including the installation of

the disconnect panel, control panel, and final

connections — must be performed by a certified

electrician and conform to all local and applicable

national codes.