Penn-Century DP-4_4M User Manual

Page 10

10

must still be taken to minimize one’s hand motion during repeated administrations of air and powder to

the animal.

CLEANING AND CARE OF DRY POWDER INSUFFLATORS™

•

Cleaning the main device body – Dry methods preferred

- In general, the Dry Powder Insufflator™ is constructed of sterilizable, chemical and heat resistance

materials. Due to the complex nature of the valve system inside, dry methods of cleaning are

preferred. The user may employ an air compressor for this purpose, if one is available in the lab, or

purchase a container of compressed air, (“Dust Off” or similar) such as is commonly used to clean

computer keyboards or camera lenses.

- To clean the Sample Chamber, detach it from the Air Intake and direct a small stream of air or other

compressed gas into it. Do not thrust the nozzle of the air source down into the Sample Chamber –

as it may damage to the valve assembly. Do not use excessively forceful compressed air sources as

they may damage the device. If you have particular questions or concerns about acceptable

methods of cleaning, feel free to contact us with your questions.

- NOTE: Each time the device is cleaned with compressed air, it may remove the residue of powder

that has coated the interior of the device. This may renew the static effects that will cause sample

loss the next time the device is used. For consistency of dose administration, if possible, do not blow

off the powder residue that remains inside the device after each use in an animal, as this may

refresh the static properties of the device and make it more difficult to have consistent

dosing. As noted above, the optimal sample delivery efficiency is achieved (nearly 100% with

lactose) after two or three deliveries, when the static electrical effects have become saturated.

- Liquid methods of cleaning the device, such as alcohol, organic solvents (ethanol or methanol), or

water are less desirable than use of dry methods. Liquids, especially water, may work themselves

into small crevices inside the Insufflator™ where it may be difficult to fully dry out and the moisture

that remains can interfere with subsequent powder deliveries. Some users have reported that the

device can be dried after use of liquid solvents or cleaners by placing the device in a low temperature

(incubation temperature) oven at 60 degrees Fahrenheit for

Please note that dessicator systems are

designed to remove water – not solvents.

•

The stainless steel delivery tube can be removed and cleaned separately with liquid

The delivery tube of the device is hollow and detachable, and may be cleaned separately, autoclaved or

immersed in water, organic solvent or disinfectant. It should be thoroughly and completely dried – using

compressed air or by air drying it, prior to reattaching it to the body of the device. To remove the

delivery tube, simply twist the 10-32 fitting ¼-turn counterclockwise and pull the tube out. To replace,

push the stainless steel tube in to a hard stop and twist the fitting ¼-turn clockwise, or until some

resistance is felt. Do not overtighten.

•

Clearing clogged internal valves

Relatively large inclusions, agglomerations, or impurities in the powder sample may occasionally clog up

the valves of the delivery device. This is especially the case with samples that are highly hygroscopic or

absorbing humidity from the air. If this happens, you will experience considerable resistance when

attempting to deliver the air pulse, and no air will be expelled from the tip of the delivery tube.

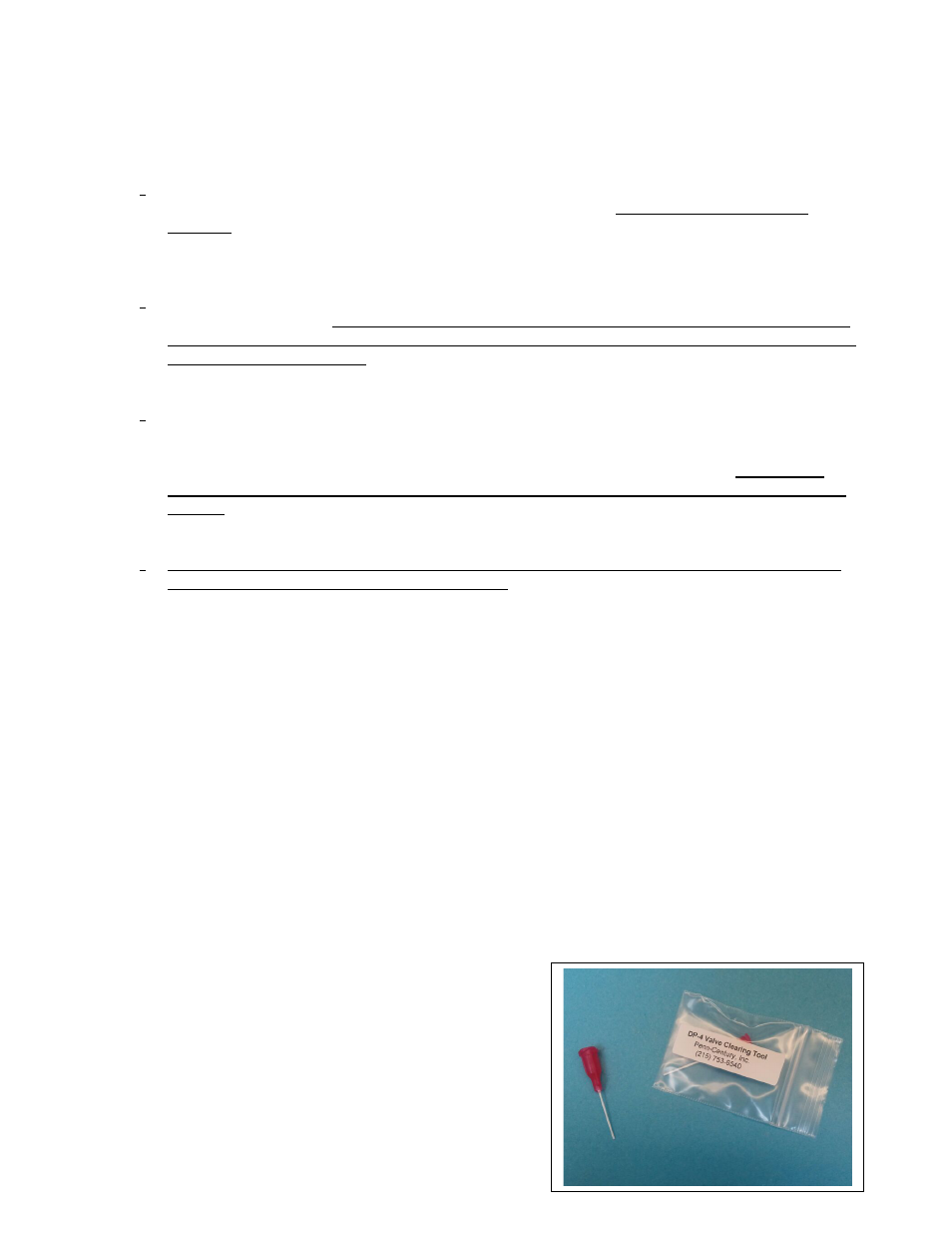

Valve Clearing Tool A small red tool with a soft white

tip has been provided with your device to permit you to

gently probe and clear powder that may have formed a

lump that is stuck in a valve inside either the Sample

Chamber or Air Intake.

Air Intake If the device is not used for long periods of

time (months), the valve assembly in the Air Intake may

occasionally stick in the closed position, making it difficult

to fill the air syringe. To open the valve, insert the valve-