Diamond Products CC7074 User Manual

Page 31

28

Lower Gearbox

Clean the lower gearbox breather vent (at end of vent

tube) using compressed air to remove oil, dirt, and slurry

every 100 hours.

Figure 32: Lower Gearbox Breather Vent

Changing the Lower Gearbox Fluid

Change the lower gearbox fluid every 100 hours.

1. Place a drain pan under the gearbox drain plug (on

back of gearbox).

2. Remove the gearbox drain plug and drain the fluid

completely. Dispose of the used fluid according to

city, state, and federal regulations.

3. Replace the drain plug and retighten to secure.

4. Lower saw to level frame.

5. Remove the red vinyl plug from the frame base

(below gearbox) to view the fluid level from the sight

glass.

6. Remove the fill cap and add Synthetic ATF fluid to

the lower gearbox to at least half full (view level

through sight glass).

7. Replace the fill cap and retighten to secure.

8. Replace the red vinyl plug in frame base.

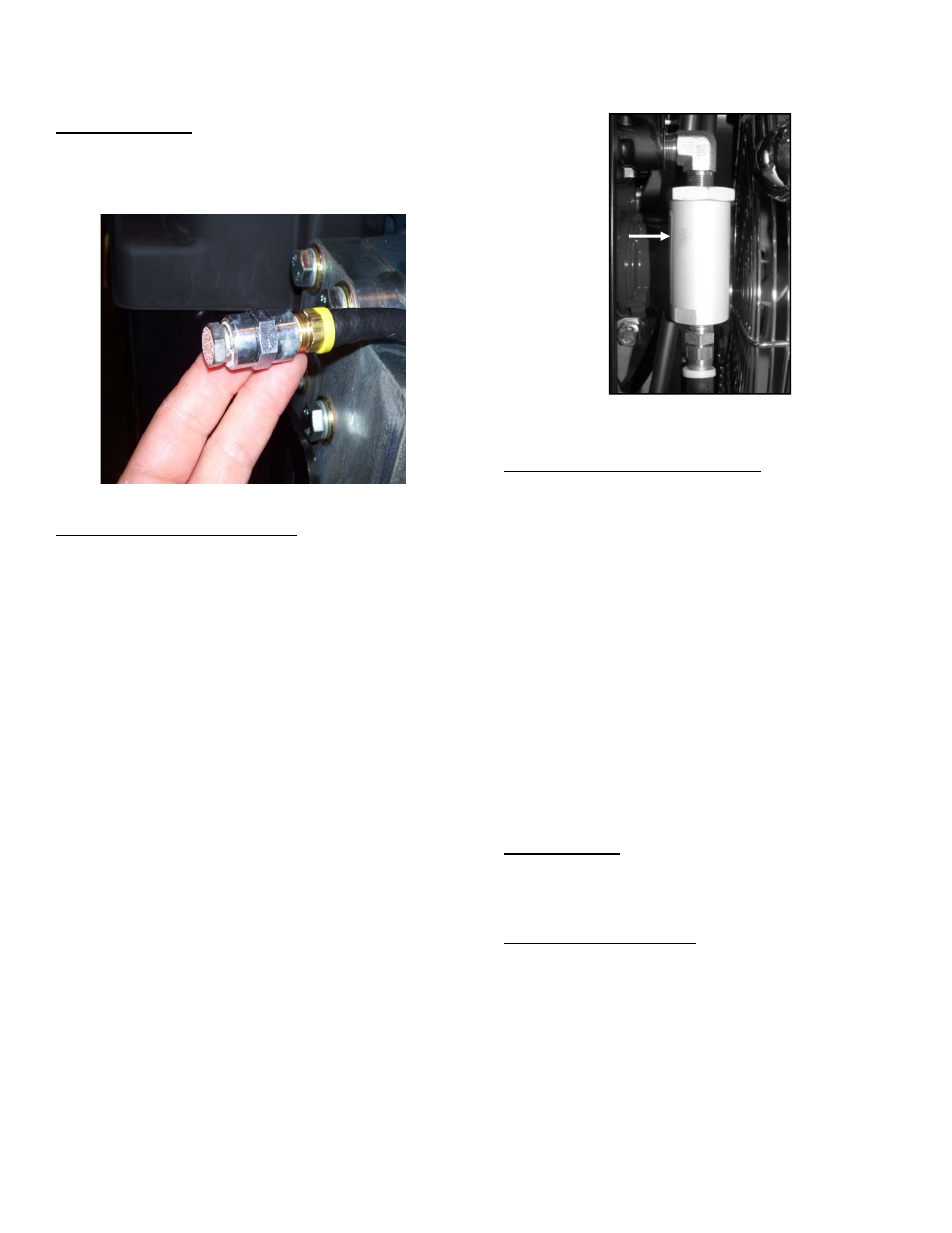

Figure 33: In-Line Oil Filter

Cleaning the In-Line Oil Suction Filter

Clean the in-line oil suction filter every 100 hours.

Replace the filter when it cannot be properly cleaned or

is damaged.

1. Lower the saw completely.

2. Place a drain pan underneath the filter.

3. Use a wrench to hold the hex filter cap in position.

Use another wrench on the barrel flats and loosen

the barrel from the cap. A very small amount of oil

may drain. Dispose of the used oil according to city,

state, and federal regulations.

4. Remove the spring and bronze element from the

barrel. Clean the inside of the barrel and the bronze

filter element using an industrial cleaning solvent.

Replace the filter if damaged or not cleanable.

5. Fit the bronze filter inside the spring and place the

assembly back into the filter barrel.

6. Retighten the filter barrel to the hex filter cap to

secure.

Belt Sheaves

The upper and lower belt sheaves may need to be

changed when changing the blade size. Refer to the

CC7074 Parts List for additional information.

Removing the Belt Sheaves

1. Loosen the two engine cradle screws.

2. Loosen the nut away from the engine foot on both

blade drive belt tension bolts.

3. Turn both blade drive belt tension bolts (large

threaded bolt on engine foot) counterclockwise to

loosen the belts.

4. Remove both sets of belts from the four sheaves.

5. Remove both setscrews from one of the sheaves.