Diamond Products CC7074 User Manual

Page 25

22

3. Reinsert the mesh strainer and retighten the strainer

cap to the filter.

Speed Control Lever

Adjusting the Lever Tension

Adjust the tension felt in the speed control lever, when

moving the lever forward and backward, to the desired

setting as necessary.

1. Remove front access panel.

2. Remove the grease cap from the pivot housing.

3. Loosen the jam nut on the opposite side of the

speed control frame using provided wrench.

4. Use the Allen wrench provided to adjust the

shoulder screw.

5. Retighten the jam nut.

6. Move the speed control lever forward and backward

to test the lever tension. Readjust the shoulder

screw/jam nut if desired.

7. Secure the grease cap to the pivot housing.

8. Replace access panel and retighten.

Adjusting the Spring Plungers

Adjust the spring plungers if the speed control lever feels

floppy or loose when moving the lever forward and

backward, or when the lever is hard to place into or out

of the Stop position.

1. Loosen both hex nuts from the speed control tube.

2. Screw the spring plungers slightly out to let the

speed control lever move easily into and out of the

Stop position. Screw the spring plungers slightly in

to let the speed control lever move forward and

backward firmly in the forward/reverse slot.

3. Retighten both hex nuts to secure.

Inner Blade Flange

Figure 16: Inner Flange

Installing the Inner Blade Flange

1. Inspect the inner flange for damages. Clean or

replace damaged components as necessary.

2. Align the flange with the blade shaft key and place

the flange onto the blade shaft.

3. Apply Loctite 262 (red) or an equivalent to the

setscrew threads.

4. Tighten the setscrew(s) into the back of the inner

flange to secure.

Removing the Inner Blade Flange

1. Remove

the

setscrew(s)

from the back of the inner

flange using an Allen wrench.

2. Carefully remove the flange from the blade shaft.

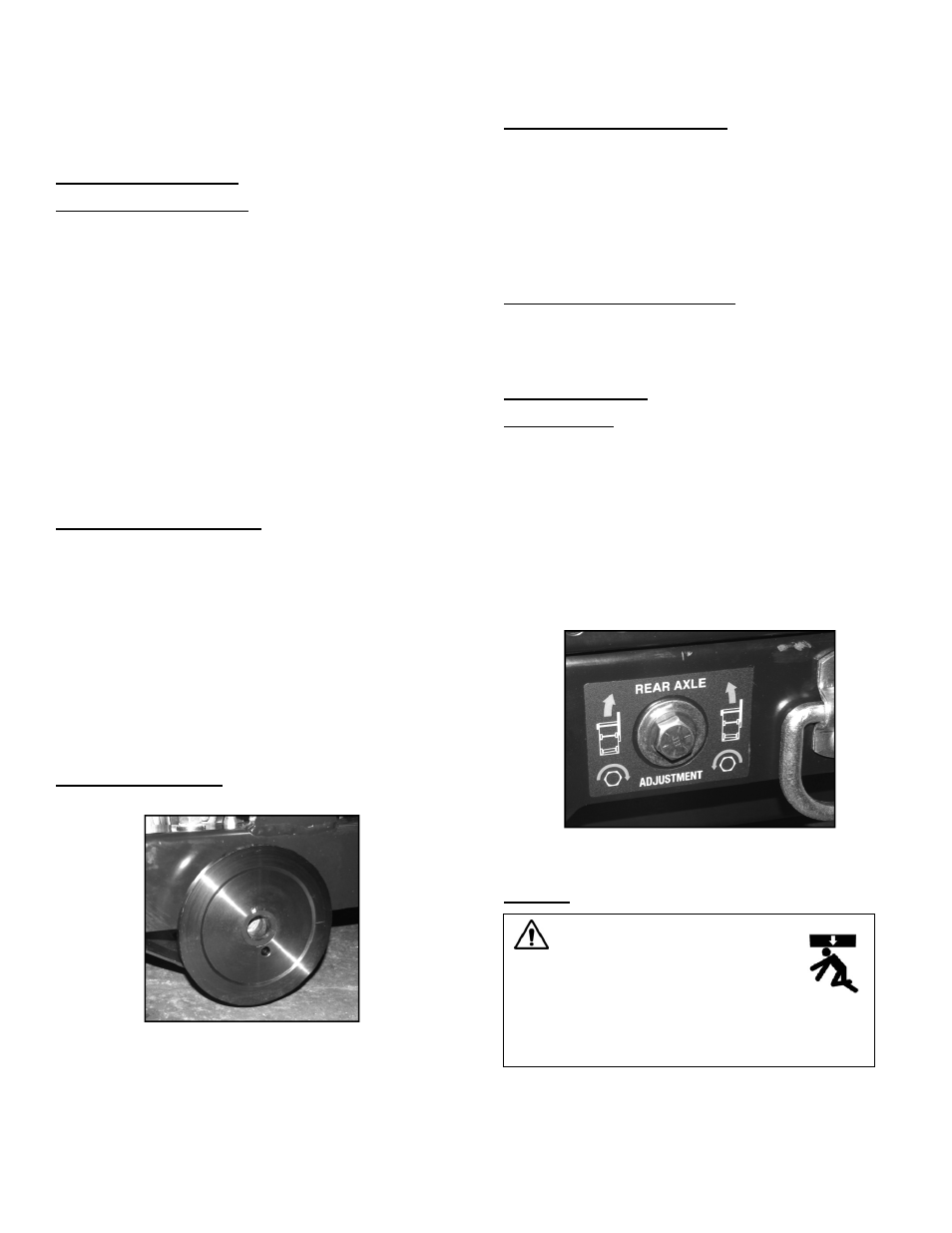

Drive Alignment

Drive Alignment

Adjust the rear axle when the saw’s drive alignment is off

(saw will not cut in a straight line). Note: The rear axle

does not have to be adjusted for straightness; it can also

be adjusted based on the specifications of the cutting

job.

1. Turn the tap bolt clockwise using the provided

wrench to adjust the drive alignment toward the

right, or counterclockwise to adjust the drive

alignment toward the left.

Figure 17: Adjustment Bolt

Wheels

WARNING

Raise the saw to a proper height for

access when working underneath

the saw. Use chocks to block the

wheels, and fit blocks or jacks under the frame

edges at the front and back of the frame.