Final heater assembly – Detroit Radiant Products Company SV Series User Manual

Page 23

Tube Heater General Manual

23

3.0

Installation

•

Baffle Assembly

Chart 3.6

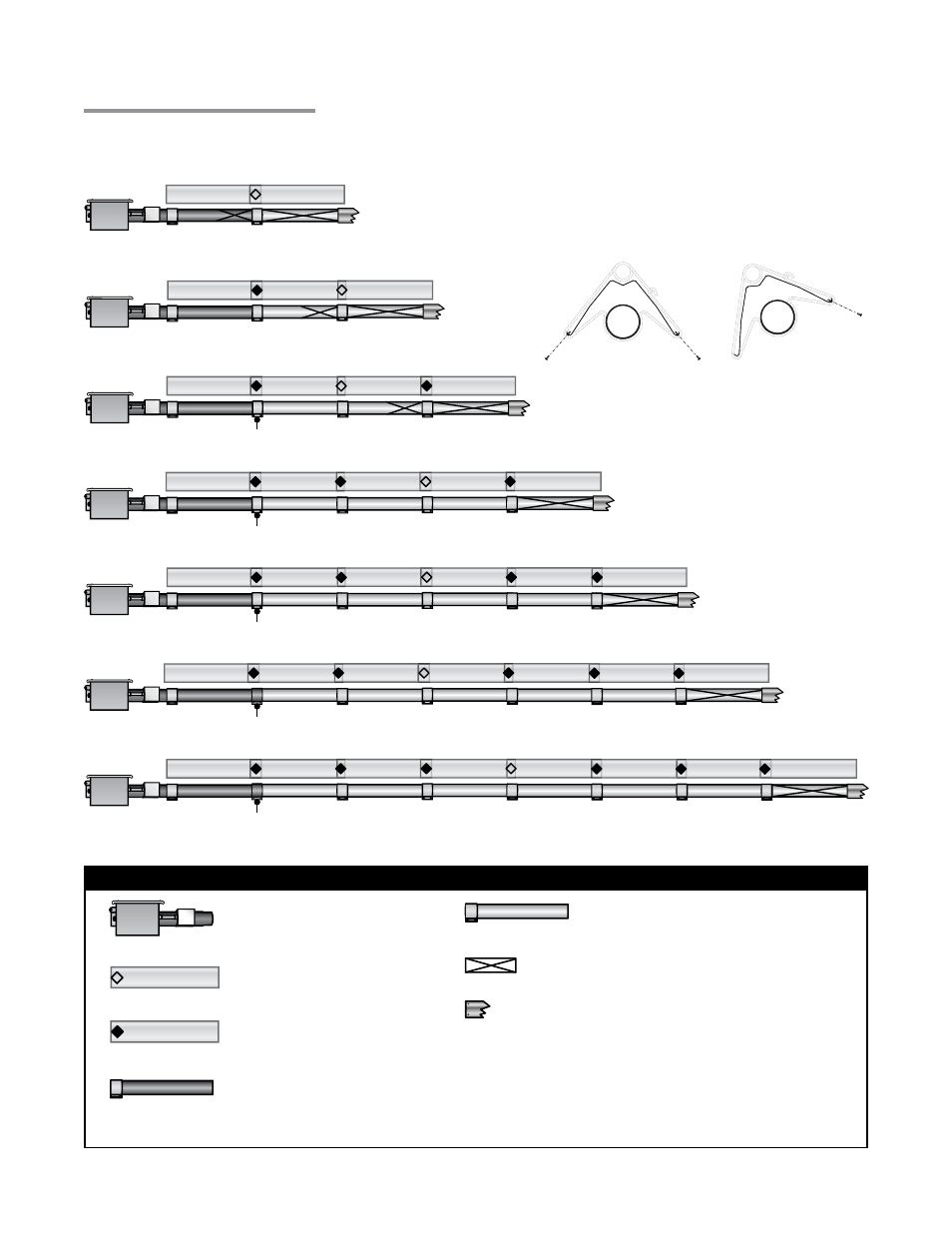

Tube Installation Sequence, Baffle Location and Secured Joints for Reflectors

30 Foot

40 Foot

*

*

*

*

*

Burner Control Box

w/16 in. Burner Tube

Key

Expansion Joint on

Reflectors

Secured Joint on

Reflectors (see note)

Primary Combustion

Chamber with Clamp

Radiant Tube

Exchanger with Clamp

Baffle Location

Secure vent material to exchanger with three #8

sheet metal screws. Seal with high temperature

silicone sealant. Do not use tube clamp.

20 Foot

Final Heater Assembly

* A secondary combustion chamber is installed as the

second tube downstream from the burner control box on

150,000 to 200,000 BTU/h models. Refer to the Series

Insert Manual for installation requirements.

50 Foot

60 Foot

70 Foot

80 Foot

Stainless steel clamp on 150,000 to 200,000

BTU/h models (P/N: TP-220).

Stainless steel clamp on 150,000 to 200,000

BTU/h models (P/N: TP-220).

Stainless steel clamp on 150,000 to 200,000

BTU/h models (P/N: TP-220).

Stainless steel clamp on 150,000 to 200,000

BTU/h models (P/N: TP-220).

Stainless steel clamp on 150,000 to 200,000

BTU/h models (P/N: TP-220).

NOTE: When securing joints on reflectors which

are rotated on an angle from horizontal, secure

joint only on top side of reflector to allow for

sufficient heater expansion and contraction.

1 to 45° Mounting Angle

0° Mounting Angle