Detroit Radiant Products Company SV Series User Manual

Page 10

3.0

Installation

•

Design Considerations

Tube Heater General Manual

10

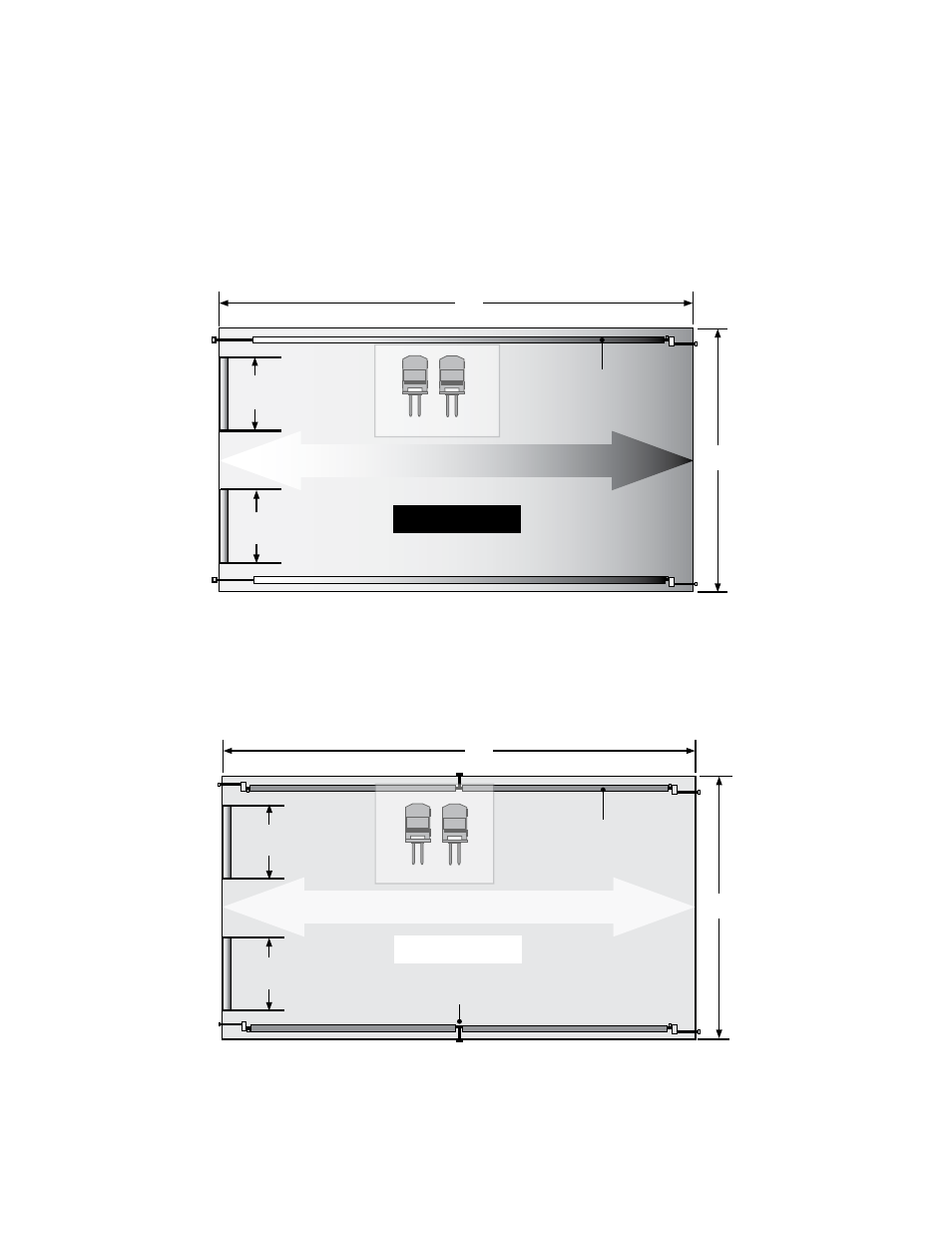

Design Scenario:

A tube heater system is being installed in a 90’ (L) x 50’ (W) x 14’ (H) space. Two overhead doors are located

at one end and an equipment storage area on one side. The calculated heat load is 400,000 BTU/h.

Figure 3.1

•

Poor Design

Figure 3.2

•

Good Design

Doors and

tracks

Too Cold

Too Hot

Equipment storage

50’

80’ - 200,000 BTU

(2 total)

Doors and

tracks

90’

Doors and

tracks

Doors and

tracks

Equipment storage

Sidewall Vent (2 total)

• Two burners (200,000 BTU each) are placed at one end, opposite the area of highest demand

(e.g., overhead doors).

• Recommended mounting heights are not observed (see Chart 3.1).

• Produces an uneven heat distribution.

• Four burners (100,000 BTU each) are placed in each corner. Burner (hotter) ends direct heat to areas of

highest heat demand.

• Recommended mounting heights have been observed.

• Distributes heat more evenly.

Gas Supply

50’

90’

Gas Supply

40’ - 100,000 BTU

(4 total)

Poor Design

Good Design

When heated, materials high in hydrocarbons (solvents, paint thinner, mineral spirits, formaldehydes, etc.)

can evaporate. This may result in odors or fumes being emitted into the environment. To correct this

problem, clean the area and/or introduce additional ventilation. The heaters themselves, when installed

and serviced in accordance with the installation manual, do not emit foul odors into the environment.

Better Heat Distribution