Zero reference – Meriam M2110L SMART LEVEL GAUGE User Manual

Page 10

9R143 Dated 3/2011

8

ZERO REFERENCE

Zeroing the gauge consists of accepting the current applied pressure value as the zero pressure reference. To set the

zero reference pressure, all pressure sources should be disconnected from the gauge, and its temperature should be

stable.

The Smart Level Gauge displays tank level as a function of the applied pressure. This pressure is linearly offset

from the zero reference value, before applying the tank level calculations.

AFFECT ON OUTPUTS

The SetPoint and Current Loop outputs are calculated based on the displayed level. Since re-zeroing the

gauge may change the displayed level, the outputs may change accordingly. For safety purposes, if the

outputs are active (defined by register P5; see page 15), an extra step is required to warn the operator and

confirm the desired action. For clarity, both scenarios are described below, step-by-step.

FACTORY ZERO

The “Factory Zero” can be restored through the serial port service only (SetPoint and Current Loop models

only). This is the value set during calibration of the sensor, and is typically 0.0.

RANGE CHECK

The Smart Gauge can be zeroed only when the applied pressure is within

±5% of sensor full scale. If the

applied pressure is greater than 5% of full scale, an error code will be displayed when zeroing is attempted.

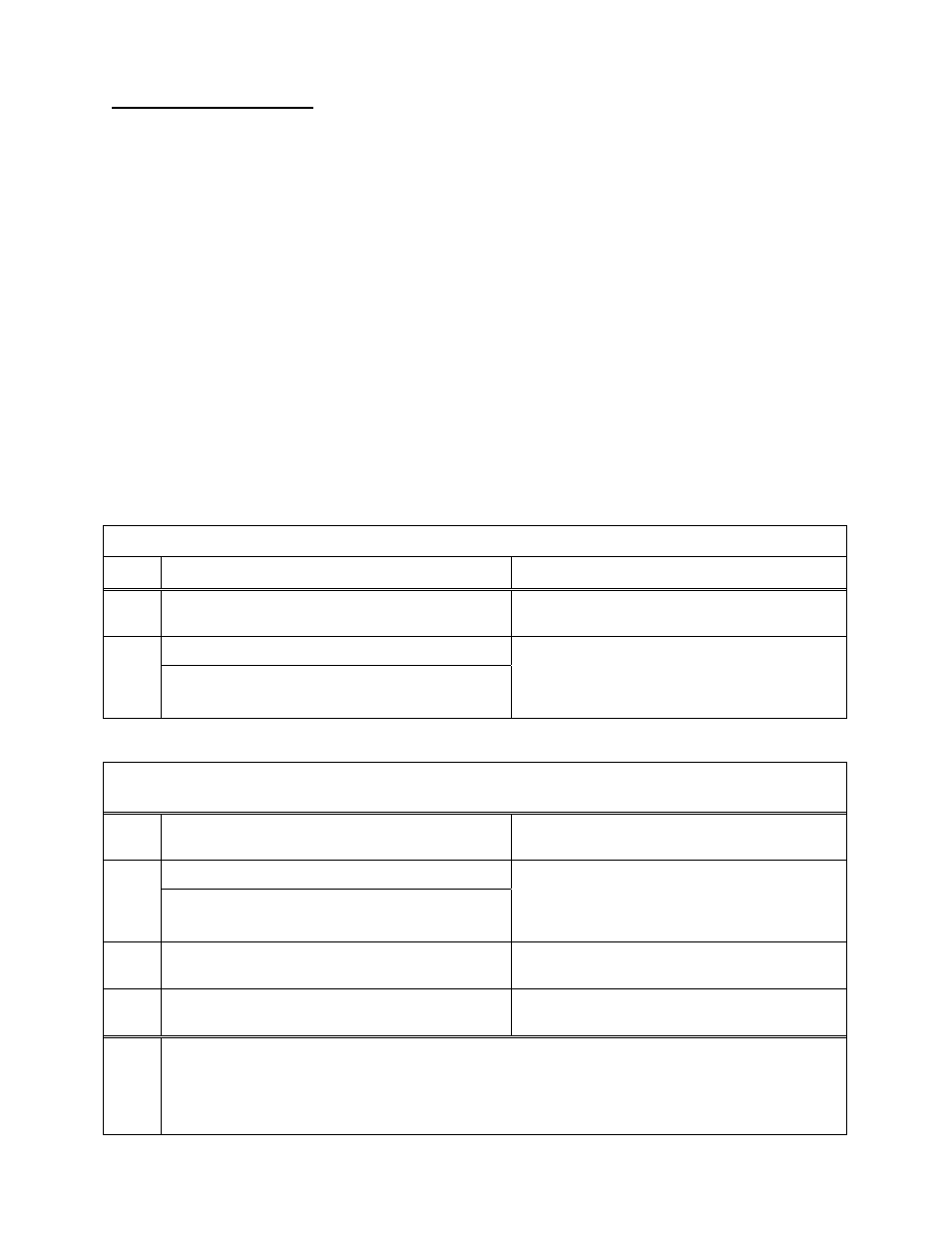

STEP BY STEP: RE-ZEROING THE GAUGE (Disabled Outputs, P5=0)

Step Action

Display

1

Gauge should be in normal Measure Mode, with

applied pressure ready for zeroing (typically vented).

Normal level display, near 0.0 (or offset from the

Residual Hydrostatic Pressure, P3).

Press the Up

↑ and Down↓ keys simultaneously.

2

If the lockout is active, the gauge will now prompt for entry of the

lockout code. Refer to “STEP BY STEP: ENTERING A

LOCKOUT CODE (When Prompted)” on page 21.

The display will flash “0000” several times while

the new zero is taken, and then return to Measure

Mode with the new zero activated.

WHEN OUTPUTS ARE ACTIVE (P5>0) ...

1

Gauge should be in normal Measure Mode, with

applied pressure ready for zeroing (typically vented).

Normal level display, near 0.0 (or offset from the

Residual Hydrostatic Pressure, P3).

Press the Up

↑ and Down↓ keys simultaneously.

2

If the lockout is active, the gauge will now prompt for entry of the

lockout code. Refer to “STEP BY STEP: ENTERING A

LOCKOUT CODE (When Prompted)” on page 21.

The display will begin countdown from

“0005” to “0000”.

3

Press PRGM/Enter

→ before the countdown

expires

1

. This acknowledges the warning.

The display will again countdown from

“0005” to “0000”.

4

Press ZERO again (Up

↑ and Down↓) before the

countdown expires

1

. This confirms the zero action.

The display will flash “0000” several times while

the new zero is taken.

Notes

1. During steps 2 or 3, if the countdown expires, the gauge will return to Measure Mode unchanged.

2. During steps 2 or 3, the Backspace

← key will abort the process and return to Measure Mode.

3. The zero reference value is snapshot immediately when the ZERO keys are pressed. This temporarily

stored value is accepted once the zeroing process is complete (or discarded if not completed).

SetPoint and Current

Loop models only