Programming – Max Machinery 120 FLOW RATE & TOTAL INDICATOR User Manual

Page 13

120-200-350 © 1993 (Rev 5/97) Max Machinery, Inc.

Page 13

Sub Menu 13 - 4-20 mA Output Calibration

To calibrate the analog output signal, first turn off all power and then connect the analog output “+”

terminal to the 24 VDC out terminal of the control. Connect the analog output “-” terminal to a

current meter and connect the other end of the current meter to the 24 VDC ground terminal. Turn

power back on and select menu 13. Press the Clear key to start the calibration process and use the

Left / Right arrow keys to adjust the current to 4 mA, then press the Enter key to enter the 4 mA

calibration point. Use the up arrow key to select the 20 mA setpoint. Press the Clear key to start the

calibration process and use the Left / Right arrow keys to adjust the current to 20 mA, then press the

Enter key to enter the 20 mA calibration point.

Sub Menu 14 - Rate 4 - 20 mA Output Range

The rate output range is programmed at both the 4 mA and 20 mA points. This permits analog rate

indications from 0 to full scale of the digitally displayed rate or a portion of the rate range. Use the up

arrow key to select the 4 mA or 20 mA setpoints and then use the Clear, number and Enter keys to

enter a rate value at each setpoint.

Sub Menu 15 - Diagnostics

The diagnostics allow the user to test the indicator display and internal memory. Press the up arrow

key for display test 1. Each of the display’s 16 characters will go to 8 with the decimal point lit. Press

the up arrow key for display test 2. Each character will go to *. Press the up arrow key for the internal

memory test. The display will read TEST IN PROCESS for three seconds while the tests are being

run. The display will read SYSTEM TEST OK for two seconds, then go back to DIAGNOSTICS if

no memory errors were detected. If the unit detects a memory error, the display will hold an error

message. The error messages are:

ROM ERROR

INTERNAL ERROR

EXTERNAL ERROR

These errors are non-recoverable. It is possible that electrical noise caused the diagnostic failure, so

the power to the unit should be cycled (turned off and then turned back on). The memory tests are

always performed at power up. If the same test fails at power up, the unit likely needs repair. If a

different test fails, or if the unit powers up normally, it is likely that the unit is experiencing electrical

noise problems. Note that the error messages for the power up memory tests may be different than the

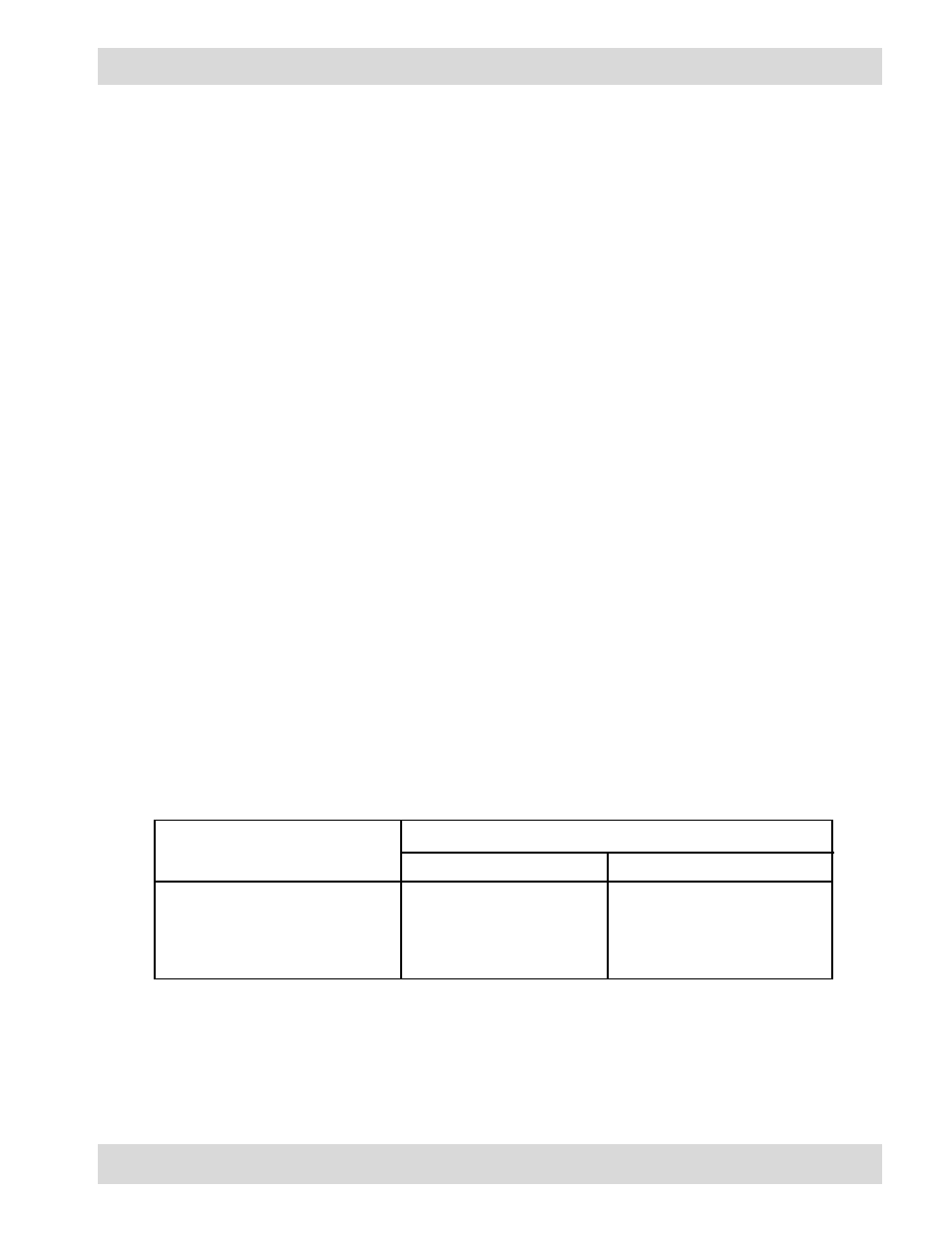

error messages for the program mode diagnostic memory tests. The following table lists each test

failure and its associated error message in each test mode.

Note that the power up diagnostic memory test performs an additional test, the external RAM

checksum. If the calculated checksum of the external RAM (the memory which holds the user

program) does not match the stored checksum, the user program has been corrupted and the message

STORE ERROR appears on the display. This error is recoverable by pressing the Reset key. The

message VERIFY PGM DATA then appears on the display for one second to prompt the user to locate

and correct program mode item(s) which may have been altered.

PROGRAMMING

Test Failure

ROM checksum error

Int. RAM bit error

Ext. RAM bit error

EXT. RAM checksum error

ROM ERROR

INTERNAL ERROR

EXTERNAL ERROR

N/A

ROM ERROR

RAM ERROR

EXT RAM ERROR

STORE ERROR

Error Message

Program Diagnostics

Power Up Diagnostics