Mallory Ignition Mr_Gasket 52000 SERIES MAGNETIC BREAKERLESS DISTRIBUTORS User Manual

Page 3

3

ACCEL

www.mrgasket.com

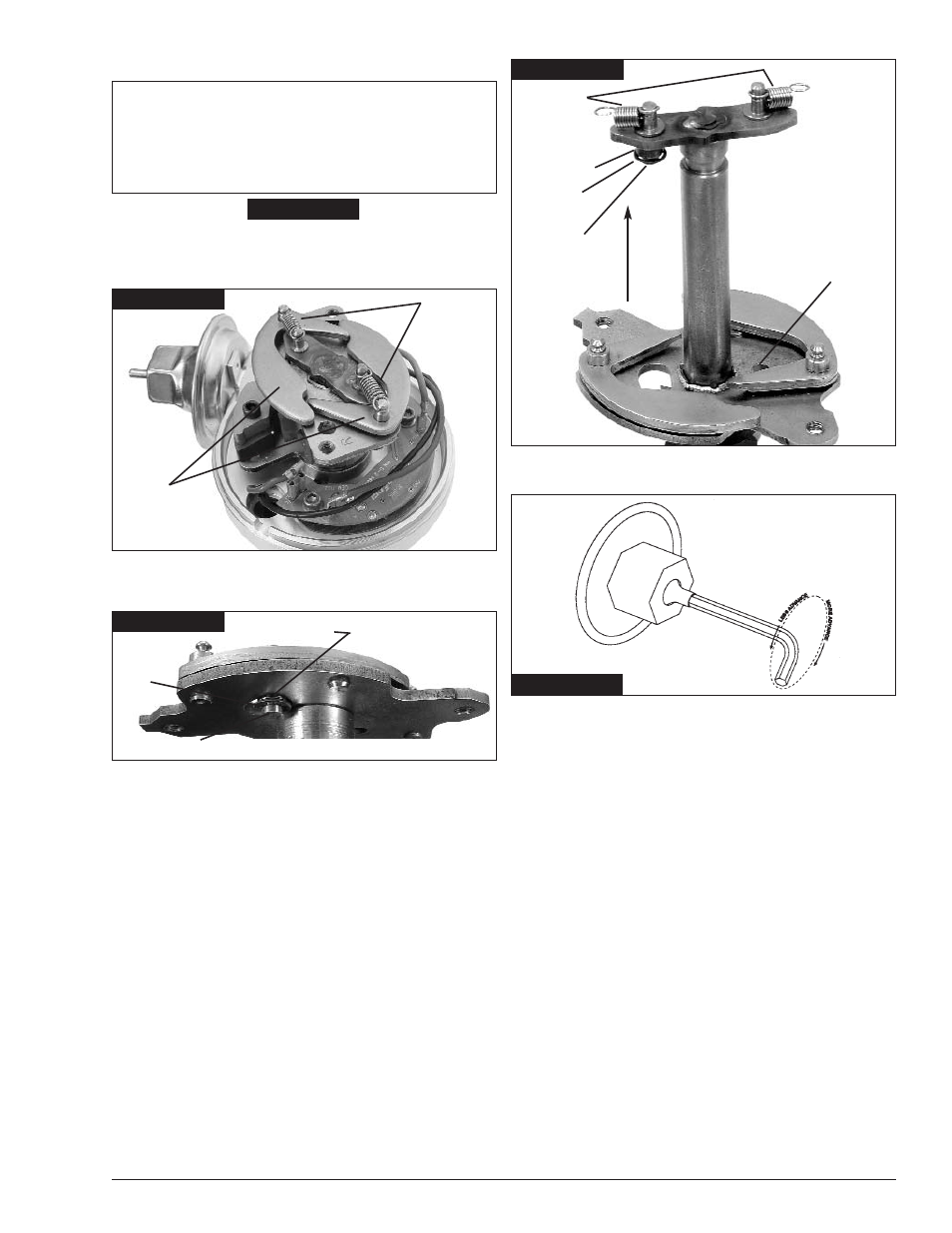

FIGURE 3

produce 10° advance (crank) at 10" of vacuum. The vacuum

advance can be adjusted by inserting a 3/32" Allen wrench into

the hose nipple on the vacuum chamber. Turn the wrench

clockwise to increase advance, counterclockwise to decrease.

See figure #7.

NOTE: Check local smog laws before adjusting the vacuum

advance.

In most cases, the vacuum advance hose should be connected to

a ported vacuum outlet on the carburetor. This is the same

location as stock. However, in some cases where a very large

camshaft is used, connecting the vacuum hose to full manifold

vacuum (near the bottom of the carburetor) will improve idle.

Vacuum Advance Lockout

If the vacuum advance is not going to be used (such as for

racing), the vacuum advance chamber can be removed and

replaced with the enclosed lockout. The lockout covers the hole in

the distributor housing and prevents the pickup plate from rotating.

To remove the vacuum chamber, you must remove the distributor

gear (and lower collar if so equipped) and remove the shaft

assembly. Remove the clip holding the pickup mounting plate

assembly. Next, remove the 2 screws holding the vacuum

chamber and the clip on the control rod. Place the lockout plate

in the distributor, making sure the pin projects through the hole in

the pickup plate assembly. Secure the lockout with the 2 screws

and retaining clip. Re-assembly the distributor.

NOTE: Check local smog laws before removing the vacuum

advance chamber.

INSTALLATION

Installing an ACCEL 52000 distributor and setting the timing is

done in much the same way as a stock distributor (see a repair

manual for more information). If another distributor is already

installed (and correctly timed) note the direction the rotor is

pointing before removing the distributor. Transfer the plug wires

to the ACCEL cap in the same order and relative locations. Install

FIGURE 4

ADVANCE

WEIGHTS

ADVANCE

SPRINGS

FIGURE 6

REMOVE STOP

BUSHING IF

INSTALLED

ROTATE

SHAFT

180º

PULL

SHAFT

UP

STOP

BUSHING PIN

REMOVE

SPRINGS

REMOVE

CLIP

SMALL

HOLE

FIGURE 5

STOP BUSHING PIN

CLIP

STOP BUSHING

IF INSTALLED

BUSHING SIZE

APPROXIMATE

CRANKSHAFT

DEGREES

Black- Smallest

16

Silver- Medium

12

Gold- Largest

8

C

▲

FIGURE 7

Advance Stop Bushing Chart

Changing the Advance Stop Bushing

Locking Out the Advance