Accel 2 – Mallory Ignition Mr_Gasket 52000 SERIES MAGNETIC BREAKERLESS DISTRIBUTORS User Manual

Page 2

www.mrgasket.com

ACCEL

2

assembly out of the distributor about two inches. If necessary,

push the pick up plate back down. Now you have better access

to remove the retainer clip on the bottom of the advance

assembly, see figure #5. Install a stop bushing and reinstall the

retainer clip. If you have disassembled the shaft and advance

assembly, reassemble them in the reverse order.

Locking out the Mechanical Advance

You may also decide to run the ACCEL 52000 distributor with a

locked out mechanical advance. To do so, first remove the cap

and rotor. Remove the advance springs and weights from the

advance assembly. Remove the roll pin from the drive gear,

remove gear and thrust washer from the shaft (if so equipped).

Make sure not to misplace the roll pin and thrust washer. Lift the

shaft assembly out of the distributor about two inches. Remove

the retaining clip and the stop advance bushing, if any are

installed. Rotate the shaft assembly 180 degrees and

reposition the stop bushing pin into the small hole in the pickup

plate using a slight amount of pressure. This is a press fit to

maintain stable timing. See figure #6. Reinstall the thrust

washer, drive gear and roll pin.

Vacuum Advance

The vacuum advance operates independently from the

mechanical advance. The vacuum chamber is factory adjusted to

installed length. How quickly the mechanical advance comes in

(or the slope of the advance curve) is controlled by the stiffness of

the springs. The stiffer the springs used, the slower the rate of

the mechanical advance. The advance stop bushing controls the

total amount of mechanical advance. The larger the size of the

bushing used, the smaller the amount of total mechanical

advance. You can also lock out the mechanical advance

altogether if you wish.

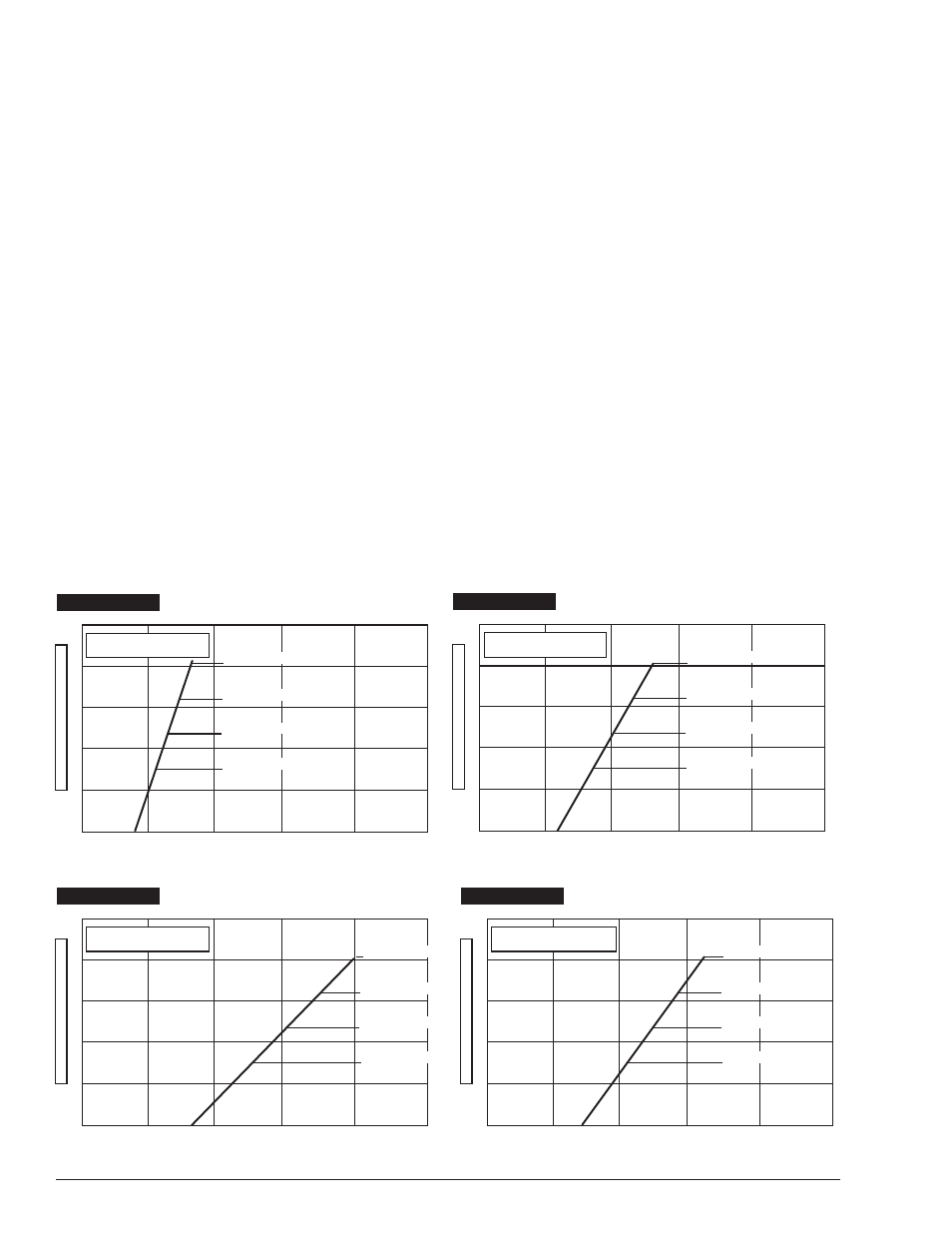

The ACCEL 52000 distributors are equipped from the factory with

two heavy gold springs. The parts kit included contains three

addition pair of colored springs; black, silver and light weight

gold. See advance curve charts Figures 2A through 2D.

Selecting and Changing the Advance Stop Bushing

There are three different advance stop bushings are supplied in a

kit with the ACCEL 52000 distributor. No stop bushings are

factory installed which yields approximately 22° degrees of

advance. If a different amount of mechanical advance is desired,

see advance stop bushing chart figure #3 to select the stop

bushing that meets your requirements. To change the mechanical

advance stop bushing, first remove the cap and rotor. Although it

is not absolutely necessary, it is easier if you also remove the

advance springs and weights from the advance assembly, see

figure #4 and also remove the roll pin from the drive gear, remove

gear and thrust washer from the shaft (if so equipped). Make

sure not to misplace the roll pin and thrust washer. Lift the shaft

Curve w/2 Light Gold Springs-

Set Initial Timing at 800 RPM

25

20

15

10

5

0

C

R

A

N

K

S

H

A

F

T

D

E

G

R

E

E

S

0

1,000

2,000

3,000

4,000

5,000

RPM

With No Stop Bushing

With Black Stop Bushing

With Silver Stop Bushing

With Gold Stop Bushing

FIGURE 2A

Curve w/2 Silver Springs-

Set Initial Timing at 1,200 RPM

25

20

15

10

5

0

C

R

A

N

K

S

H

A

F

T

D

E

G

R

E

E

S

0

1,000

2,000

3,000

4,000

5,000

RPM

With No Stop Bushing

With Black Stop Bushing

With Silver Stop Bushing

With Gold Stop Bushing

FIGURE 2B

Curve w/2 Black Springs-

Set Initial Timing at 1,600 RPM

25

20

15

10

5

0

C

R

A

N

K

S

H

A

F

T

D

E

G

R

E

E

S

0

1,000

2,000

3,000

4,000

5,000

RPM

With No Stop Bushing

With Black Stop Bushing

With Silver Stop Bushing

With Gold Stop Bushing

FIGURE 2C

Curve w/2 Heavy Gold Springs-

Set Initial Timing at 1,400 RPM

25

20

15

10

5

0

C

R

A

N

K

S

H

A

F

T

D

E

G

R

E

E

S

0

1,000

2,000

3,000

4,000

5,000

RPM

With No Stop Bushing

With Black Stop Bushing

With Silver Stop Bushing

With Gold Stop Bushing

FIGURE 2D