Mallory Ignition Mallory COMP PUMP ELECTRIC FUEL PUMP SERIES 110_140 User Manual

Page 2

WIRING PROCEDURE

Wiring the pump to an oil pressure switch will provide power only when the ignition

switch is on and the engine is running. This will prevent the pump from running if your

engine stalls. Use 14 gauge wire or larger and be sure to disconnect the battery

ground cable before wiring the pump. Refer to Figure 3 when connecting the pump to

an oil pressure switch.

The pump may be wired directly to the ignition switch ON terminal and grounded to

the frame or battery. Refer to Figure 4 when connecting the pump to the ignition switch

ON terminal.

MAINTENANCE PUMP DISASSEMBLY

If your pump fails to produce adequate pressure, it may require cleaning. Follow the

steps below to disassemble and clean your Mallory Electric Fuel Pump. Refer to

Figure 5 while performing the following steps.

Step 1

Remove the pump from the vehicle and clean pump exterior. Place the pump on its

side on a clean work surface. Scribe or draw a line acrosss the pump housing, port

plate and fuel chamber so that you can reassemble the pump correctly.

Step 2

Remove the two fuel chamber screws from the bottom of the pump. Remove the fuel

chamber and port plate. NOTE: Do not drop the Gerotor from the pump cavity.

Step 3

Separate the port plate from the fuel chamber. Inspect the flame arrestor screen in the

fuel chamber and clean it if necessary.

Step 4

Place your hand beneath the Gerotor and hold the pump in an upright position. The

Gerotor should slide out of the pump housing and into your hand. NOTE: Observe the

position of the Gerotor and be careful not to reverse it when you reassemble

the pump.

Step 5

Release the jam nut on the bypass plug. Mark the bypass plug location and count the

number of turns required to remove it. Remove the bypass spring and plunger.

Inspect the plunger. The plunger surface should be clean and slide freely in the

chamber. Check the plunger pad and remove any debris embedded in its surface.

Reinstall the bypass spring and plunger. Clean the bypass plug. Apply thread sealant

compound to the bypass plug threads. Install the bypass plug. Tighten the jam nut.

Step 6

Clean the Gerotor and install it in the pump housing. Inspect the O-ring and gasket.

Replace them if necessary. Place the gasket and port plate on the fuel chamber. Install

the fuel chamber assembly on the pump housing. Torque the fuel chamber screws to

24 in/lbs.

2

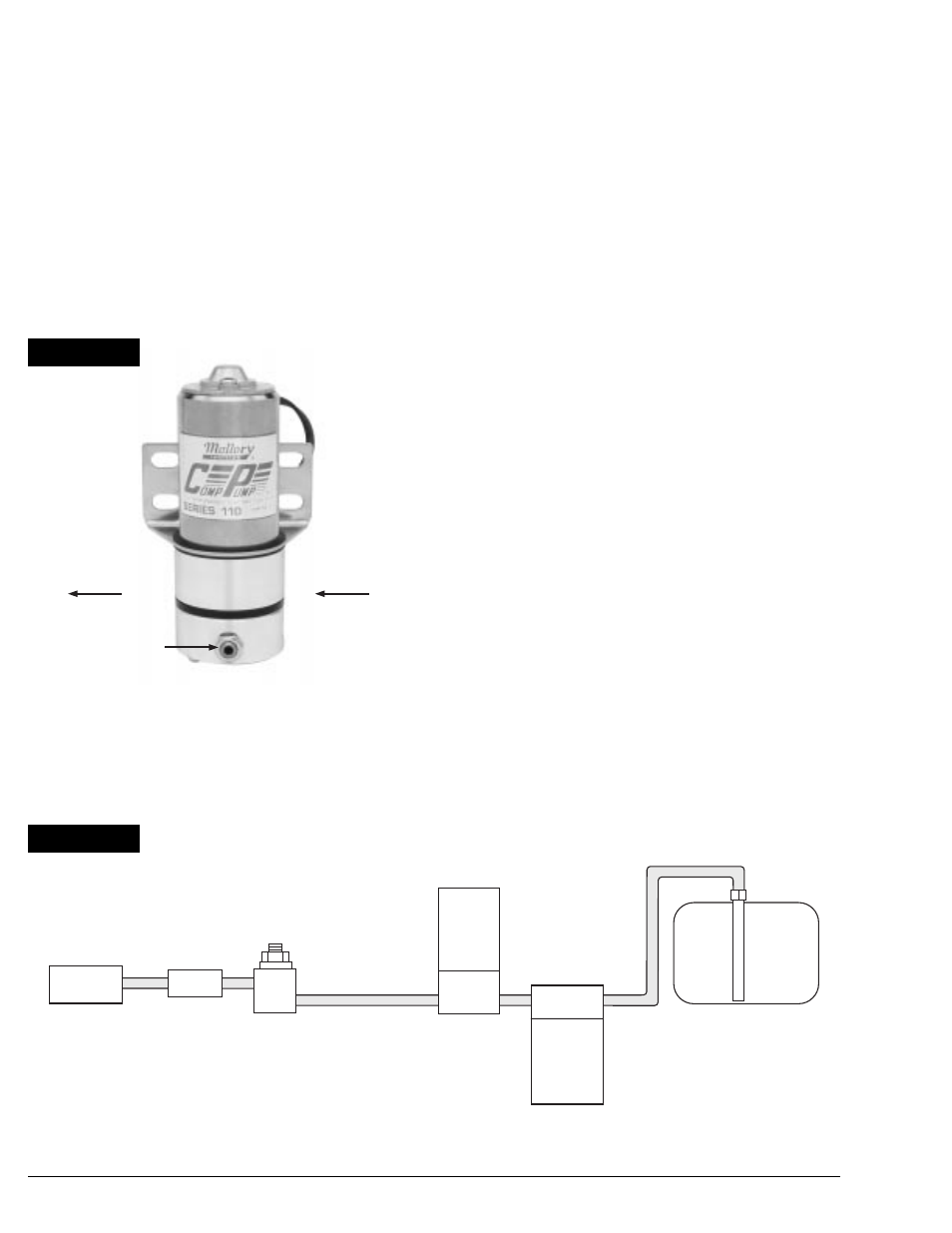

FIGURE 2A

FUEL PUMP KIT PART NO. 4110 (OPTIONAL FUEL

PRESSURE REGULATOR), 4140 OR 4141 WITH FUEL

PRESSURE REGULATOR PART NO. 4207 OR 4209

REGULATOR

CARB.

FUEL

FILTER

FUEL

PUMP

FUEL

FILTER

COMP

®

FILTER

PART NO.

3140

FUEL

TANK

BLACK WIRE

()

RED WIRE

(+)

TOP

3/8" NPT

OUTLET

3/8" NPT

INLET

BYPASS ADJUSTMENT

(BYPASS PLUG AND JAM

NUT)

BOTTOM

FIGURE 1

MOUNTING PROCEDURE

Step 1

Mount the pump as close as possible to the fuel tank (at or below the level of the fuel

tank pickup) in a well ventilated area with minimual exposure to road debris. Avoid

exposing the pump and fuel lines to moving parts and hot surfaces, such as the

exhaust system. NOTE: Increasing distance between the pump and tank will

decrease pump efficiency.

Step 2

Using the pump mounting bracket as a template, locate mounting holes on a solid

member, such as the vehicle shassis. Drill holes for 5/16 bolts. See Figure 1. NOTE:

To ensure against a potential fire hazard from pump flooding, mount the

pump in a vertical position with the motor on top.

Step 3

Connect fuel lines as shown in Figure 2 (A, B, C, or D). If your fuel system requires

a fuel pressure regulator, proceed to the instructions with the fuel pressure regulator.