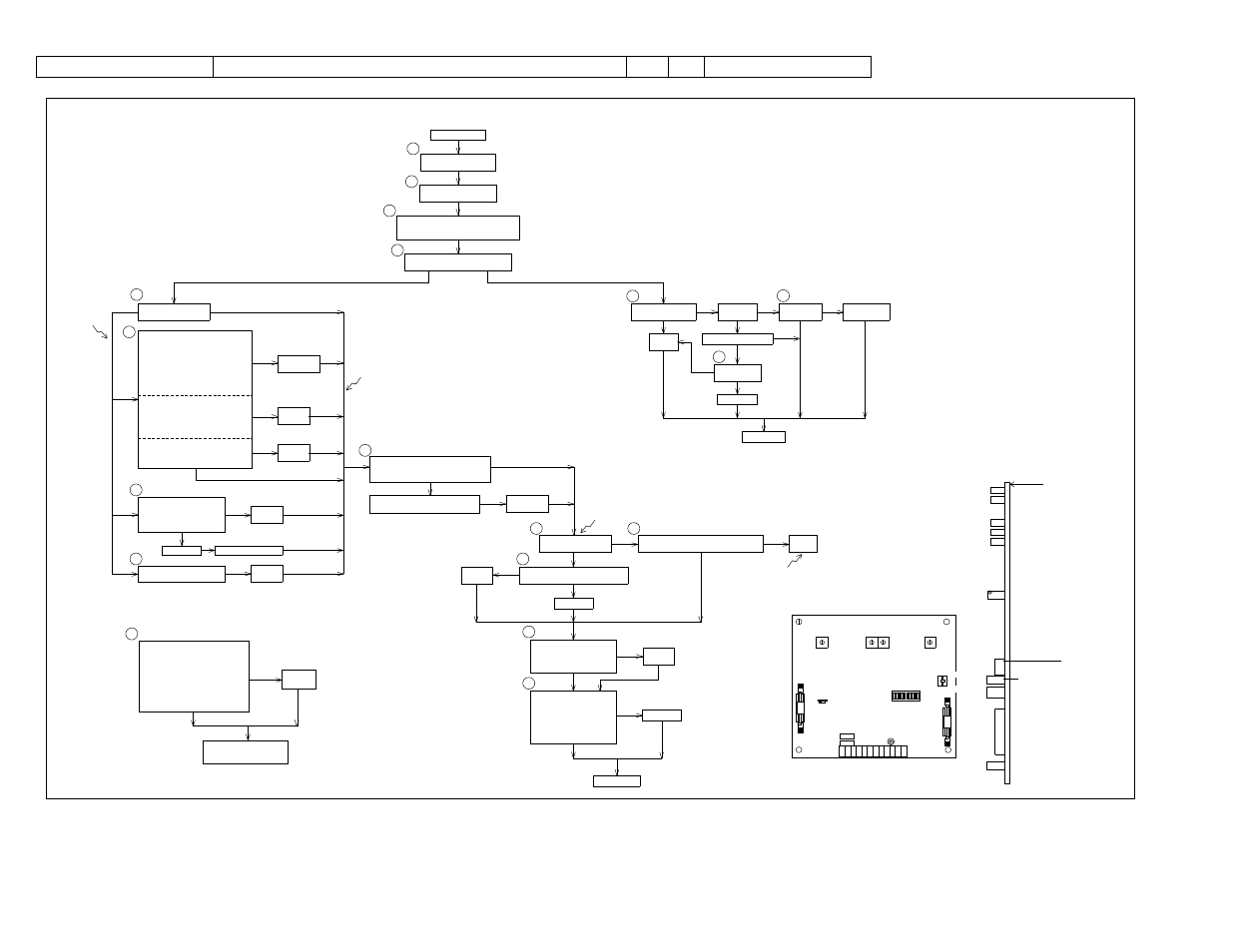

Troubleshooting diagram – Liquid Controls T650N SERIES User Manual

Page 14

Sponsler, Inc.

T650N Series Cryogenic Truck Totalizer

pg

14 DOC# MN-650

GO TO STEP 15

NO GO

1) SW ITCH S12 TO W /T.C.

2) DEPRESS S9 FOR 15 SEC

OBSERVE DISPLAY-

N2 = 53 COUNTS

O2 = 58 COUNTS

AR = 57 COUNTS

CO2 = 59 COUNTS

CCO2 = 57 COUNTS

REPLACE

650F & D

NO GO

1) SW ITCH S12 TO W /O T.C.

2) SET S3, 4, 5, 6 TO 7777

3) DEPRESS S9 FOR 15 SEC.

OBSERVE S8 DISPLAYED

12

NO GO

REPLACE

650F & D

REPLACE T.C.

SW ITCH S12 TO W /O T.C., DEPRESS S9

OBSERVE DISPLAY COUNTS

NO GO

NO GO

GO

11

REFER TO TURBINE

ASSY. DRAW ING

REBUILD

TURBINE

'COUNTS'

OPEN DISCHARGE VALVE PERMITTING VAPOR

BLOW BY - OBSERVE DISPLAY COUNTS

SYSTEM

COUNT

10

DEPRESS S9 - OBSERVE

DISPLAY COUNTS

REPLACE

PROBE CABLE

'ON'

D0 & D2 'ON' PROBE CABLE SHORTED

D0 & D3 ‘ON’ PROBE CABLE ‘OPEN’

9

T.C. ASSY

DISCONNECT RTD & CONNECT TEMP RANGE

PLUG - OBSERVE D0, D2, D3 ‘OFF’

(AL) (-) (+)

8

REPLACE

650F & D

D6, D7 'OFF' (NOT FLASHING)

D8, D9 ‘OFF’

SW ITCH S12 TO W /T.C.

REPLACE T.C.

'FLASHING

'

NO GO

REPLACE

650F & D

7

D4. D5 'OFF' (NOT FLASHING)

1) SW ITCH S12 TO W /O T.C.

2) DEPRESS S9, OBSERVE D4,

D5 ‘FLASHING’

REPLACE

650F & D

REPLACE

P/U COIL

REPLACE

SIGNAL CABLE

'OFF'

NO GO

NO GO

'ON'

6

5) CONNECT J1

6) TURN POW ER ‘ON’

OBSERVE D1, D2 ‘ON’

4) CONNECT P/U COIL

J1-7 (W HT)

→ J1-8 (BLK)

1800-2100

Ω WARM

AS LOW AS 250

Ω COLD

J1-9 (SHD)

→ J1-7 OR 8 =

∞

Ω

D1,2 'OFF'

1) TURN POW ER ‘OFF’

2) DISCONNECT J1

3) DISCONNECT P/U COIL

J1-7 (W HT)

→ PIN ‘A’ = 0 Ω

J1-8 (BLK)

→ PIN ‘B’ = 0 Ω

J1-9 (SHD)

→ J1-7 or 8 =

∞

Ω

J1-7 (W HT)

→ J1-8 (BLK) =

∞

Ω

NO GO

5

DEPRESS S9, OBSERVE

D1-D10 ‘ON’ OR FLASHING

DIAGNOSTIC LED'S

17

18

16

GO TO STEP 5

OK

REPLACE T.C.

BLOW N DISCONNECT J2

OBSERVE FUSES

FUSES

BLOW N

O.K

YES

CHANGE DEFECTIVE FUSE

REPLACE S1

POW ER SW ITCH

NO

CHECK J1-5,6

FOR 12 VDC

BLOW N

GO

CHECK FUSES

F1 & F2

'OFF'

POW ER CIRCUITS

REPLACE

650F & D

'ON'

DEPRESS S9, OBSERVE

D8, 9, 10 ‘ON’

4

3

2

1

'

OFF'

'

ON

'

TURN POW ER 'ON' & OBSERVE THAT

THE DISPLAY IS EITHER ‘ON’ OR ‘OFF’

ON TC ASSY CHECK THAT: JU7 INSTALLED,

PRODUCT SELECTOR IN CORRECT POSITION

& IF EQUIPPED SENSITIVITY=11 O’CLOCK

CHECK SENSITIVITY ADJUST

ON T650F=11 O’CLOCK

CHECK AND SECURE ALL

ELECTRICAL CONNECTIONS

‘IT DOESN'T W ORK"

1) CONNECT J1

2) CLOSE & SECURE LID

NO GO

REPLACE

RTD

15

1) TURN POW ER ‘OFF’

2) DISCONNECT J1

3) DISCONNECT TEMP RANGE PLUG

4) CONNECT RTD

J1-11 (W HT)

→ J1-12 (BLK) =

114.4

Ω = 98.6 °F

20.25

Ω = -320 °F

25.75

Ω = -298 °F

24.50

Ω = -303 °F

90.0

Ω = -10° F

RTD TEST

BASIC CONCEPTS

1) DISPLAY ‘ON’

2) ALL DIAGNOSTIC LEDS ‘ON’ OR ‘FLASHING’

3) ALL T.C. RANGE LEDS ‘OFF’

4) DISPLAY COUNTS

5) SYSTEM ACCURACY

6) VAPOR BLOW BY GENRATES COUNT

T.C. 100

Ω CALIBRATION PROCEDURE

A) DISCONNECT RTD

B) INSTALL TEMP CAL PLUG

C) SET PRODUCT SELECTOR ON T.C. TO #8

D) CALIBRATION ADJUSTMENT-

D2 ‘ON’ (-) ADJUST UNTIL D2 ‘OFF’

D3 ‘ON’ (+) ADJUST UNTIL D3 ‘OFF’

E) DISCONNECT TEMP CAL PLUG

F) CONNECT RTD

G) RETURN PRODUCT SELECTOR ON T.C. TO

CORRECT PRODUCT

0 = O

2

1 = N

2

2 = A

R

JU7

D0

D2

D3

TEMPERATURE

COMPENSATOR

BOARD

SENSITIVITY

W/O TC

W/TC

SYSTEM TEST

CW

FACTORING BOARD

F1

S12

R1

S9

J2-A

D1-D10

J3-A

F2

J1

S3

S4

S5

S6

REV C

1 2 3 4 5 6 7 8 9 101112

PROCEED TO

STEP FOR

OFF LED

'ON' OR FLASHING

PROCEED TO

STEP 9

TROUBLESHOOTING DIAGRAM

REPLACE T.C.

14

13

COUNTS

ACCURACY

TEST

GO

GO

‘OFF’

PRODUCT

SELECTOR

0 - 0

2

1 - N

2

2 - A

R

CAL 100

Ω ADJUST

(ALARM)

(-)

(+)