Liquid Controls T650N SERIES User Manual

Page 10

Sponsler, Inc.

T650N Series Cryogenic Truck Totalizer

pg

10 DOC# MN-650

MODEL 820 TEMPERATURE COMPENSATOR

Introduction

The Model 820 Temperature Compensator is a highly sophisticated electronic temperature compensation system

designed to correct flow information based on product temperature. Inserted between the signal source and recording

electronics, the temperature compensator will automatically add or subtract pulses from the pulse train based on

temperature of the product being delivered. The Model 820 is designed to accommodate up to 8 different products

(field selectable via a rotary switch) with the density and non-linearity of the temperature probe and each product being

acknowledged. Data transfer via wireless (IR) communications is available to print product selection, temperature,

correction factor and accumulated corrected total on the Model SP824 Portable Ticket Printer.

Theory of Operation

As product flows through the pipeline, a turbine located in the product spins and electrical pulses are generated and

sent to the temperature compensator. The number and frequency of these pulses corresponds to the amount of

product flow and the flow rate.

As the product in the pipeline heats or cools, the density and volume of the product change. When the volume of

product changes, the turbine spins faster or slower since the turbine flowmeter is a volumetric measuring device even

though the AMOUNT (measured by weight) of product is not changed. Model 820 performs its function first by

amplifying and conditioning signals from a pickup coil or other small signal device. The temperature of the product is

then read via an RTD temperature probe. Model 820 then adds or subtracts incoming pulses based on the

temperature/density of the product and the product’s correction curve.

As long as the product flowing past the temperature sensor is within range for the product, the temperature

compensator will automatically correct for the density of the product. If the product is not within the correct

temperature range, or the temperature probe fails, the compensator will turn on the alarm LED and modify the

temperature correction factor (TCF).

The TCF is modified based on the jumper installed at the jumper option block of the 820 (Ref. Drawing SCI-820-

CONN-VOL-9-01 & Table “OPTION JUMPER” on the next page). If no jumper is installed, the correction factor will be

set for no compensation (TCF = 1.00). If the “B” jumper is installed, the 820 will stop accepting incoming pulses during

alarm condition, resulting in no count during an alarm condition. If the “C” jumper is installed, the compensator reverts

to ‘alarm’ temperature and corresponding TCF for the selected product (Ref the ‘Model 820 EPROM’ table for a listing

of products, temperature compensation range, and default alarm temperature).

The pump control output is used in conjunction with the PCM-100 module to disable the pump when the product is

above the proper temperature for delivery. If the 820 detects a complete temperature probe failure (temperature

reading above 200

o

C), the pump will be enabled so as not to prevent delivery. A timer to continue to disable the pump

after the temperature probe detects that the product is within the correct temperature range for delivery may be

activated by installing jumper ‘D’. This enabled delay allows the entire system to reach temperature before delivery is

allowed. Once the pump is enabled, the product temperature may go out of range for 10 seconds before the pump is

disabled. Once the pump is disabled, the initial delay time will be imposed before the pump is again enabled.

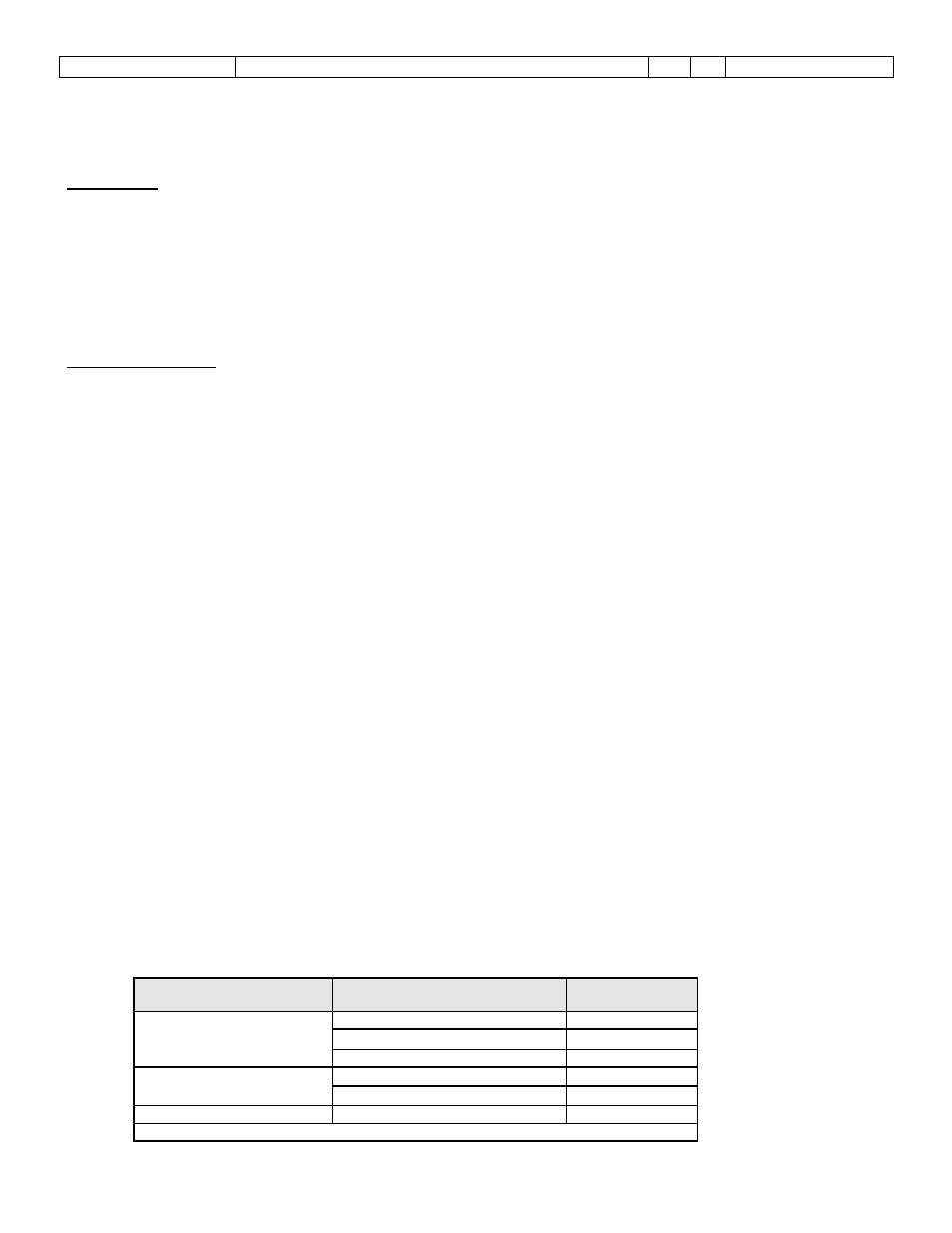

The delay times are based on the EPROM version installed on the Model 820 and the product selection. The following

table lists each version and the associated time delays (The EPROM installed on the 820 will be labeled with the

version).

EPROM

PRODUCT

DELAY TIME

(minutes)

M820-VO1-9

LOX & LIN

10

LAR

15

ALL OTHERS

1

M820-VO1-8

LOX, LIN, & LAR

12

ALL OTHERS

5

M820-VO1-7

ALL PRODUCTS

5

ANY OTHER VERSION HAS NO TIME DELAY BUILT IN