Controlled Products Systems Group K24M User Manual

Model k series, Pc board loop detect ors, Engineering excellence

Model K Operating Instructions 12-19-03 (551-1100-00).doc

4

RENO A&E P/N 551-1100-00

Reno A & E

4655 Aircenter Circle

Reno, NV 89502-5948 USA

Telephone: (775) 826-2020

Fax: (775) 826-9191

Website: www.renoae.com

E-mail: [email protected]

Engineering Excellence!

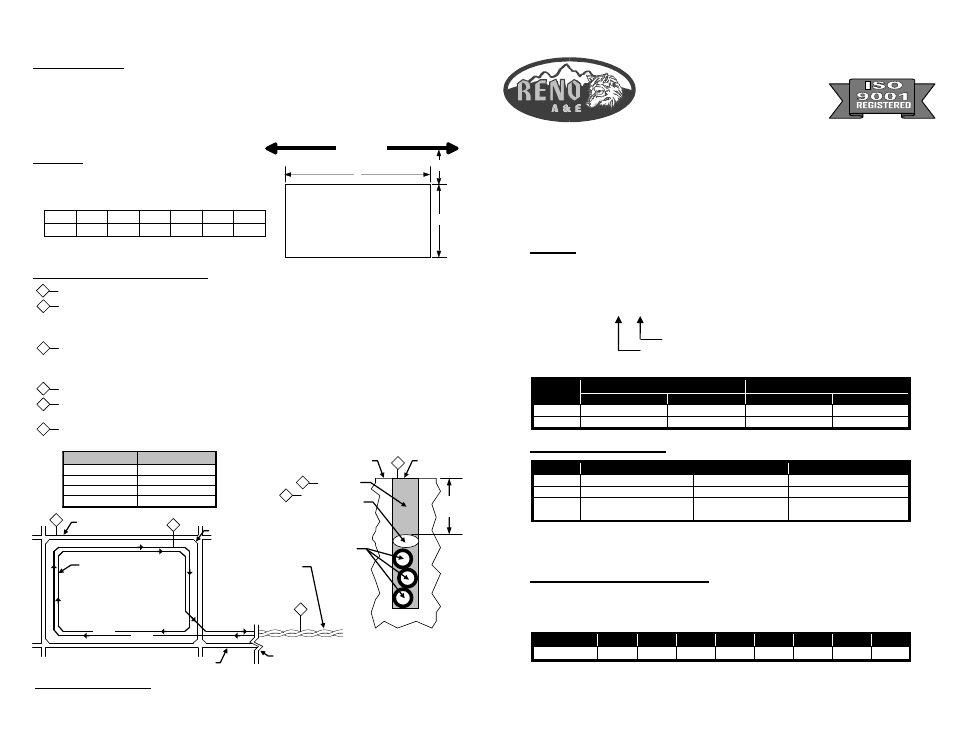

L o o p I n s t a l l a t i o n

The vehicle detection characteristics of the inductive loop detector are greatly influenced by the loop size

and proximity to moving metal objects such as gates. Vehicles such as small motorcycles and high-bed

trucks can be reliably detected if the proper size loop is selected. If the loop is placed too close to a moving

metal gate, the detector may detect the gate. The diagram below is intended as a reference for the

dimensions that will influence the detection characteristics.

General Rules

1. The detection height for a loop is 2/3rds the shortest leg (A or

B) of the loop. Example: Short leg = 6’ then Height = 4’ (2/3 x

6).

2. As leg A is made longer, distance C will need to increase.

3. For reliable detection of small motorcycles, legs A and B

should not exceed 6 feet.

L o o p I n s t a l l a t i o n - S a w C u t T y p e

1

Mark the loop layout on the pavement. Remove sharp inside corners that can damage the loop wire insulation.

2

Set the saw to cut to a depth (typically 2" to 2.5") that insures a minimum of 1" from the top of the wire to pavement

surface. The saw cut width should be larger than the wire diameter to avoid damage to the wire insulation when placed

in the saw slot. Cut the loop and feeder slots. Remove all debris from the saw slot with compressed air. Check that the

bottom of the slot is smooth.

3

It is highly recommended that a continuous length of wire be used to form the loop and feeder to the detector. Loop wire

is typically 14, 16, 18, or 20 AWG with cross-linked polyethylene insulation. Use a wood stick or roller to insert the wire

to the bottom of the saw slot (do not use sharp objects). Wrap the wire in the loop saw slot until the desired number of

turns is reached. Each turn of wire must lay flat on top of the previous turn.

4

The wire must be twisted together a minimum of 6 twists per foot from the end of the saw slot to the detector.

5

The wire must be held firmly in the slot with 1" pieces of backer rod every 1 to 2 feet. This prevents the wire from

floating when the loop sealant is applied.

6

Apply the sealant. The sealant selected should have good adhering properties with similar contraction and expansion

characteristics to that of the pavement material.

O P E R A T I N G I N S T R U C T I O N S F O R

Model K Series

PC BOARD LOOP DETECT ORS

I

General

The Model K can be configured for 24 VAC or 120 VAC input power and Fail Safe

or Fail Secure mode of operation.

The model number designates the configuration as follows:

Model K-XXX-X

Blank or S. Blank = Fail Safe, S = Fail Secure.

24 or 120. 24 = 24 VAC input, 120 = 120 VAC input.

Please verify source voltage before applying power.

Fail Safe

Fail Secure

Relay

Power Failure

Loop Failure

Power Failure

Loop Failure

A

Call

Call

No Call

No Call

B

No Call

No Call

No Call

No Call

II

Indicators and Controls

Status

Power LED

Detect LED

Fail LED

Off

No power or low power

Output Off

Loop OK

On

Normal power

Output On

Open Loop

Flash

N/A

4 Hz

– 2 second

timing delay

1Hz - Shorted Loop

3/sec - Prior Loop Failure

Note: If the supply voltage drops below 75% of the nominal supply voltage, the

power LED will turn off, providing a visual check of low supply voltage. Model K

detectors operate with supply voltage as low as 70% of nominal supply voltage.

Sensitivity Level Rotary Switch

The 8-position rotary switch selects one of eight sensitivity levels as shown below.

Zero (0) is the lowest and seven (7) is the highest, with the normal (factory default)

being three (3). Use the lowest sensitivity setting that detects the desired vehicles.

Position

0

1

2

3

4

5

6

7

L/L

1.28%

0.64%

0.32%

0.16%

0.08%

0.04%

0.02%

0.01%

A =

6 ft

9 ft

12 ft

15 ft

18 ft

21 ft

C =

3 ft

4 ft

4.5 ft

5 ft

5.5 ft

6 ft

A

B

C

A = Loop dimension parallel to the gate

B = Loop dimension perpendicular to the gate

C = Distance of the loop from the gate

SLIDE GATE

Recommended Loop Wire:

Reno LW-120 for 1/8" slots

Reno LW-116-S for 1/4" slots

1

3

1/8" to 1/4" SAW SLOT

THE WIRE IS

CONTINUOUSLY WOUND

IN THE LOOP SAW SLOT

FOR THE REQUIRED

NUMBER OF TURNS (2

turns shown)

turn 2

turn 1

REMOVE SHARP

INSIDE CORNERS

FEEDER SLOT

END OF SAW CUT

4

THE WIRES MUST BE

TWISTED TOGETHER

6 TWISTS PER FOOT

FROM THE END OF

THE SAW CUT TO

THE DETECTOR

ROAD SURFACE

MIN

1"

SAW SLOT

SEALANT

BACKER ROD

1" piece

spaced about

every 1'

LOOP WIRE

3 TURNS

2

6

5

LOOP PERIMETER NUMBER OF TURNS

10 feet - 13 feet

4

14 feet - 26 feet

3

27 feet - 80 feet

2

81 feet and up

1