Controlled Products Systems Group B3 User Manual

Page 2

3

Presence Hold Time (DIP Switch 7)

Output A always functions as a presence output. DIP switch 7 can be used to select one of two presence hold

times; Limited Presence or True Presence

TM

. Both modes provide a Call output when a vehicle is present in

the loop detection zone. True Presence

TM

is selected when DIP switch 3 is OFF. If DIP switch 3 is ON, Limited

Presence is selected. Limited Presence will typically hold the Call output for about one to three hours. True

Presence

TM

will hold the Call as long as the vehicle is present in the loop detection zone provided that power is not

interrupted or the detector is not reset. True Presence

TM

time applies only for normal size automobiles and trucks

and for normal size loops (approximately 12 ft

2

to 120 ft

2

). The factory default setting is OFF (True Presence

TM

Mode).

Relay B Output Mode (DIP Switch 8)

Relay B has two modes of operation; Pulse or Presence. Its output mode is controlled by DIP switch 8. When set

to operate in Pulse Mode (DIP switch 8 ON), Relay B outputs a 250 millisecond pulse when a vehicle enters the

loop detection zone or when a vehicle leaves the loop detection zone. (See the Relay B Pulse Mode section on

page 2 for details.) When set to operate in Presence Mode (DIP switch 8 OFF), the output of Relay B is the same

as that of Relay A. (See the Presence Hold Time section above for details.) The factory default setting is ON

(Pulse Mode Relay B) unless dual presence (DP) operation is specified, in which case the factory default setting is

OFF (Presence Mode Relay B).

III. Call

Memory

When power is removed for two seconds or less, the detector automatically remembers if a vehicle was present and a Call

was in effect. When power is restored, the detector will continue to output a Call until the vehicle leaves the loop

detection zone (loss of power or power dips of two seconds or less will not bring a gate arm down onto cars as they wait

at the gate).

IV.

Failed Loop Diagnostics

The FAIL LED provides an indication of whether or not the loop is currently within tolerance. If the loop is out of

tolerance, the FAIL LED indicates whether the loop is shorted (one Hz flash rate) or open (steady ON). If and when the

loop returns to within tolerance, the FAIL LED will turn off to indicate that the loop fault condition has been corrected

and that the loop is once again within tolerance.

The Model B detector automatically stores the last loop failure type in non-volatile memory. To determine the type of

loop failure that has last occurred, press and hold the FREQ pushbutton for at least three seconds. When the FAIL LED

begins flashing at one Hz rate with a 5% duty cycle, release the FREQ pushbutton. The detector will then display the

last loop failure type detected (if any). This indication will be displayed one time for about fifteen seconds unless

terminated by pressing the RESET or FREQ pushbutton. The non-volatile memory used to store the last loop failure

type is automatically cleared each time it is interrogated.

V. Pin

Connections

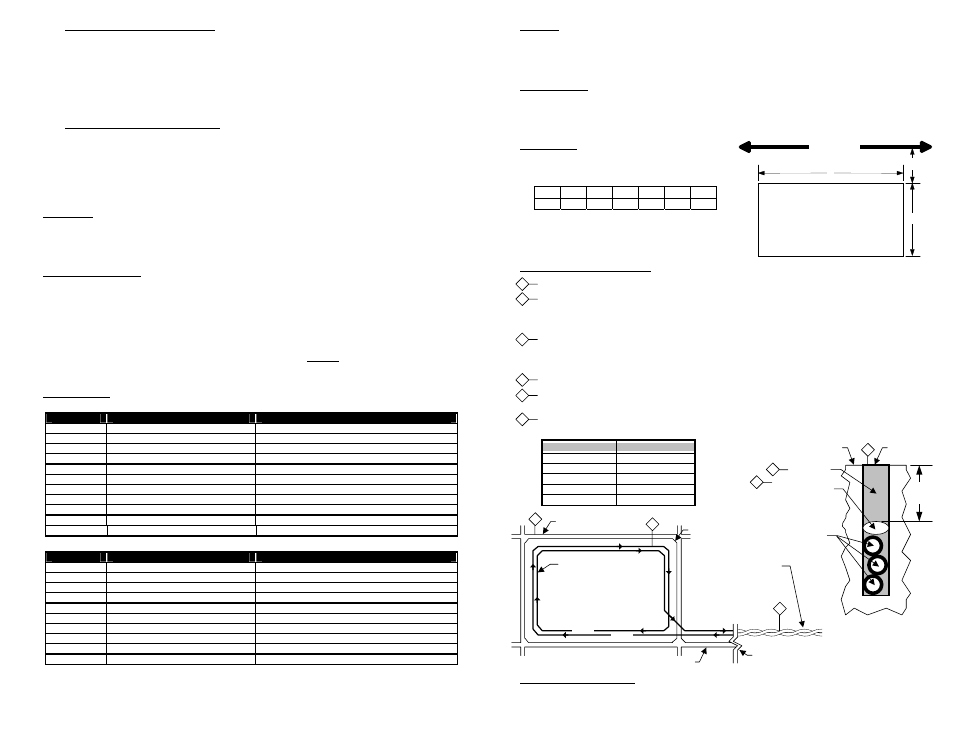

Models B-3, B-4, and B-8 (Reno A&E Wiring Harness Model 802-4)

Pin

Wire Color

Function

1

Black

AC Line / DC +

2

White

AC Neutral / DC Common

3

Orange

Relay B, Normally Open (N.O.)

4

Green No

Connection

5

Yellow

Relay A, Common

6

Blue

Relay A, Normally Open (N.O.)

7

Gray Loop

8

Brown Loop

9

Red

Relay B, Common

10

Violet or Black / White

Relay A, Normally Closed (N.C.)

11

White / Green or Red / White

Relay B, Normally Closed (N.C.)

Models B-1, B-5, and B-35 (Reno A&E Wiring Harness Model 801-4)

Pin

Wire Color

Function

A

White

AC Neutral / DC Common

B

Brown

Relay A, Normally Open (N.O.)

C

Black

AC Line / DC +

D

Red Loop

E

Orange Loop

F

Yellow

Relay A, Common

G

Blue

Relay A, Normally Closed (N.C.)

H

Green Chassis

Ground

I

Violet

Relay B, Common

J

Gray

Relay B, Normally Open (N.O.)

NOTE: All pin connections listed above are with power applied, loop(s) connected, and no vehicle detected.

Model B Op Instr 2006 11 07

P/N 551-0202-02

4

VII. Warnings

Separately, for each loop, a twisted pair should be created consisting of only two (2) loop wires running the entire

distance from the loop to the detector (including runs through all wiring harnesses) at a minimum of six (6) complete

twists per foot. For trouble free operation, it is highly recommended that all connections (including crimped

connectors) be soldered.

VIII. Loop

Installation

The vehicle detection characteristics of an inductive loop detector are greatly influenced by the loop size and proximity to

moving metal objects such as gates. Vehicles such as small motorcycles and high bed trucks can be reliably detected if

the proper size loop is selected. If the loop is placed too close to a moving metal gate, the detector may detect the gate.

The diagram below is intended as a reference for the dimensions that will influence the detection characteristics.

General Rules

1. The detection height of a loop is 2/3 the shortest leg (A

or B) of the loop. Example: Short leg = 6 feet,

Detection Height = 2/3 x 6 feet = 4 feet.

A =

6 ft

9 ft

12 ft

15 ft

18 ft

21 ft

C =

3 ft

4 ft

4.5 ft

5 ft

5.5 ft

6 ft

2. As the length of leg A is increased, distance C must also

increase.

3. For reliable detection of small motorcycles, legs A and B

should not exceed 6 feet.

Loop Installation - Saw Cut Type

1

Mark the loop layout on the pavement. Remove sharp inside corners that can damage the loop wire insulation.

2

Set the saw to cut to a depth (typically 2" to 2.5") that ensures a minimum of 1" from the top of the wire to pavement

surface. The saw cut width should be larger than the wire diameter to avoid damage to the wire insulation when placed in

the saw slot. Cut the loop and feeder slots. Remove all debris from the saw slot with compressed air. Check that the

bottom of the slot is smooth.

3

It is highly recommended that a continuous length of wire be used to form the loop and feeder to the detector. Loop wire

is typically 14, 16, 18, or 20 AWG with cross-linked polyethylene insulation. Use a wood stick or roller to insert the wire to

the bottom of the saw slot (do not use sharp objects). Wrap the wire in the loop saw slot until the desired number of turns

is reached. Each turn of wire must lay flat on top of the previous turn.

4

The wire must be twisted together a minimum of 6 twists per foot from the end of the saw slot to the detector.

5

The wire must be held firmly in the slot with 1" pieces of backer rod every 1 to 2 feet. This prevents the wire from floating

when the loop sealant is applied.

6

Apply the sealant. The sealant selected should have good adhering properties with contraction and expansion

characteristics similar to those of the pavement material.

A

B

C

A = Loop dimension parallel to the gate

B = Loop dimension perpendicular to the gate

C = Distance of the loop from the gate

SLIDE GATE

1

3

1/8" to 1/4" SAW SLOT

THE WIRE IS

CONTINUOUSLY WOUND

IN THE LOOP SAW SLOT

FOR THE REQUIRED

NUMBER OF TURNS (2

turns shown)

turn 2

turn 1

REMOVE SHARP

INSIDE CORNERS

FEEDER SLOT

END OF SAW CUT

4

THE WIRES MUST BE

TWISTED TOGETHER

6 TWISTS PER FOOT

FROM THE END OF

THE SAW CUT TO

THE DETECTOR

Recommended Loop Wire:

Reno A&E LW-120 for 1/8" slots

Reno A&E LW-116-S for 1/4" slots

ROAD SURFACE

MIN

1"

SAW SLOT

SEALANT

BACKER ROD

1" piece spaced

about every 1'

LOOP WIRE

3 TURNS

2

6

5

LOOP PERIMETER NUMBER OF TURNS

10 feet - 13 feet

5

14 feet - 26 feet

4

27 feet - 45 feet

3

46 feet - 100 feet

2

100 feet and up

1