Aeld plug-in loop detection, Loop installation, Important – Controlled Products Systems Group AELD User Manual

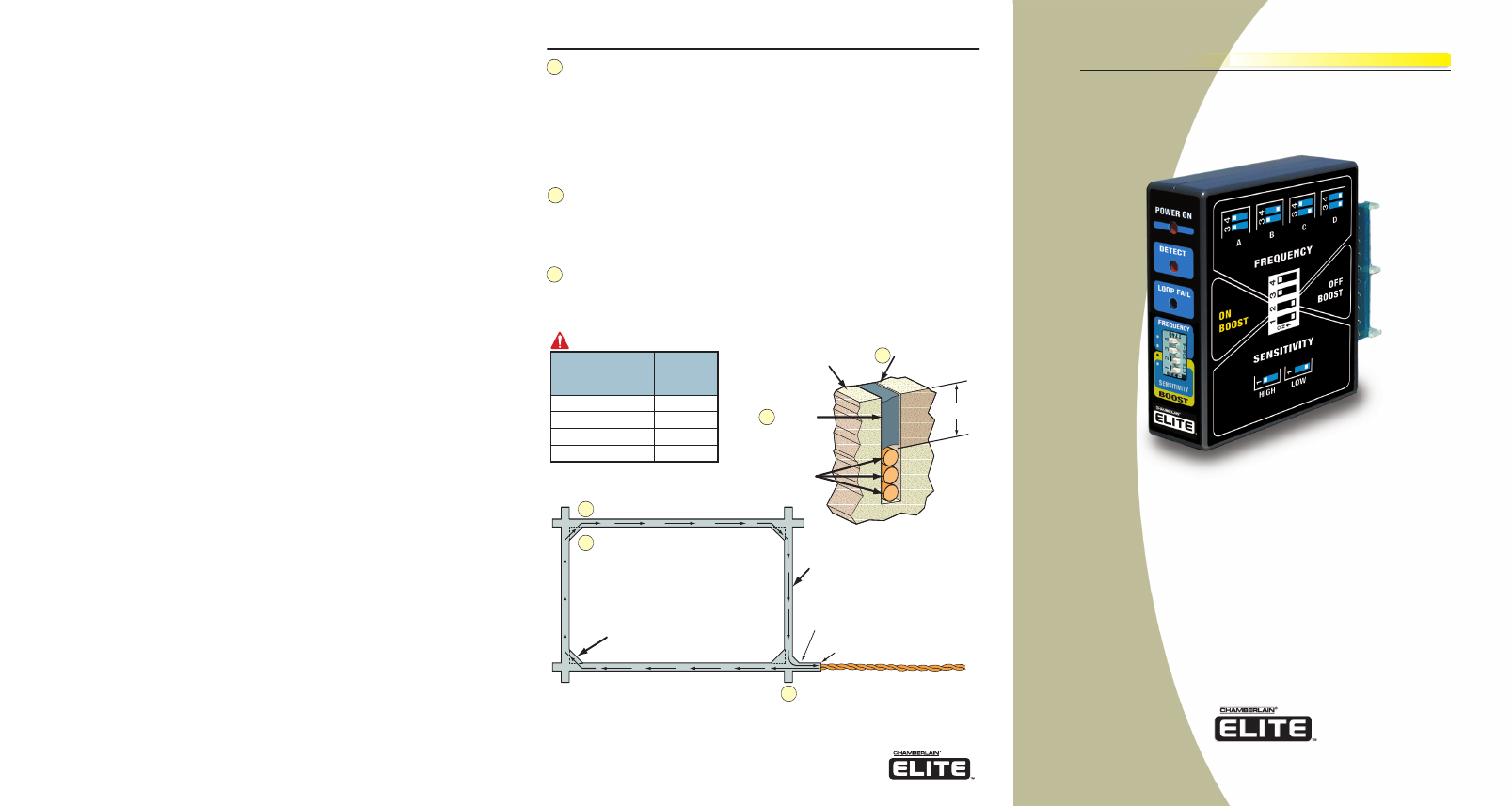

Page 2: 10 feet - 13 feet loop perimeter

These high quality loop detectors are for use with the

OmniControl™ Board available on Chamberlain Elite’s

commercial line and other enabled controllers. With

Chamberlain Elite's proven design and integration tech-

nology, these component detectors will make installation

of loop detection systems simple.

845 Larch Avenue Elmhurst, Illinois 60126-1196

www.chamberlain.com

W

a

rn

in

g

:

C

h

a

m

b

e

rl

a

in

E

li

te

d

o

e

s

n

o

t

w

a

rr

a

n

t

n

o

r

a

s

s

u

m

e

s

li

a

b

il

it

y

fo

r

#

A

E

L

D

L

o

o

p

D

e

te

c

to

rs

in

s

ta

ll

e

d

in

n

o

n

C

h

a

m

b

e

rl

a

in

E

li

te

e

n

a

b

le

d

c

o

n

tr

o

ll

e

rs

.

for the OmniControl™ and other Chamberlain Elite

#AELD enabled controllers.

#AELD Plug-In Loop Detection

now with

BOOST CONTROL

01-50969B

The loop itself must be a continuous length of wire without any breaks or

splices. The loop wire can be 14, 16 or 18 gauge stranded wire with

either a cross-linked polyethylene (XLPE) or polyester insulation.

Wrap the loop wire in the loop slot using a wooden stick or roller to

insert the wire to the bottom of the saw slot until the desired number of

turns are reached. (Caution: do not use a sharp object) Each turn of wire

must lay flat on top of the previous turn.

The wire must be twisted a minimum of 6 turns per foot from the end of

the feeder slot to the detector to minimize noise or interference. If a splice

is required in the feeder cable, solder each splice and protect with a

moisture proof seal.

Apply the sealant. The sealant selected should have good adhering properties

with similar contraction and expansion characteristics as the pavement

material.

Loop Installation

10 feet - 13 feet

Loop

Perimeter

Important

Number

of Turns

4

3

14 feet - 26 feet

27 feet - 80 feet

2

1

81 feet and up

1/8" to 1/4"

Saw Slot

Feeder Slot

End of Saw Cut

1

The wire is continuously wound in

the loop saw slot for the required

number of turns. One turn shown.

(Refer to table above)

The wire must be twisted together

6 twists per foot from the end of

the saw cut to the detector

4

1/8" to 1/4"

Saw Slot

Road Surface

Sealant

Loop Wire

(3 Wires Shown)

Min 1"

2

5

3

Remove Sharp

Inside Corners

For Technical Support:

1-800-528-2806

5

4

3

© 2005 the chamberlain group, inc. – all rights reserved