Controlled Products Systems Group AX3 User Manual

Page 2

2

3

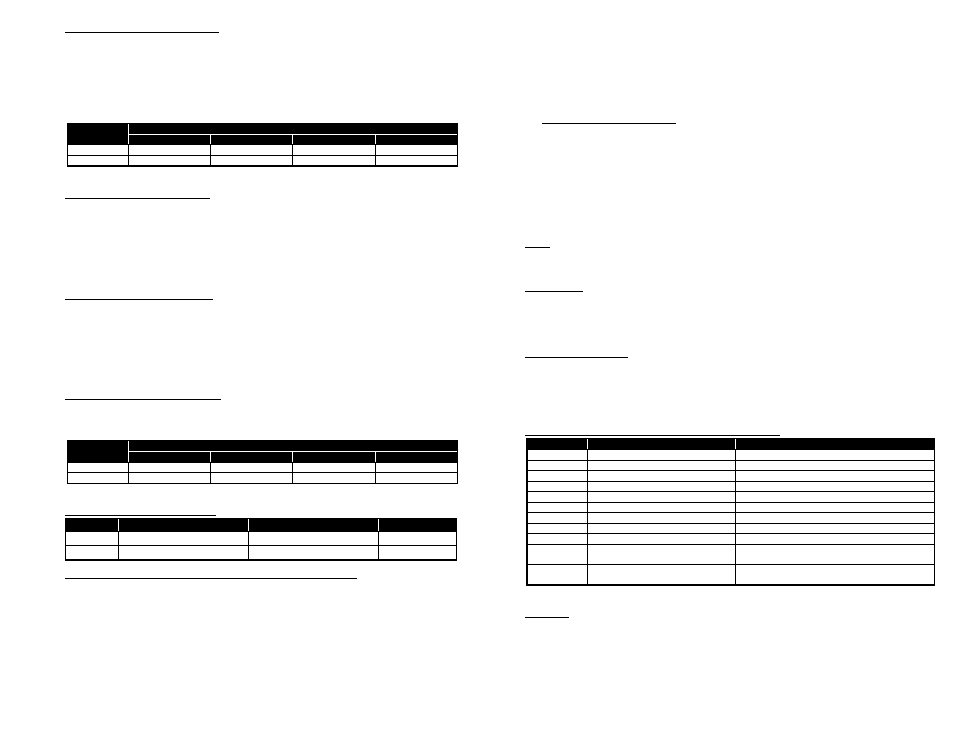

Frequency (DIP Switches 1 and 2):

In situations where loop geometry forces loops to be located in close proximity to one another, it

may be necessary to select different frequencies for each loop to avoid loop interference, commonly

known as crosstalk. DIP switches 1 and 2 can be used to configure the detector to operate at one of

four frequencies corresponding to Low, Medium / Low, Medium / High, and High as shown in the

table below.

NOTE: After changing any frequency switch setting(s), the detector must be reset by momentarily

changing one of the other switch positions or pressing the front panel RESET pushbutton.

Switch

Frequency

Low (0)

Medium / Low (1)

Medium / High (2)

High (3) *

1

ON

OFF

ON

OFF *

2

ON

ON

OFF

OFF *

* Factory default setting.

Presence / Pulse (DIP Switch 3):

The output relay has two modes of operation: Presence and Pulse. When set to operate in Presence

mode (DIP switch 3 OFF), an internal DIP switch can be used to select one of two presence hold

times; Limited Presence or True Presence

TM

. When set to operate in Pulse mode (DIP switch 3 ON),

the internal DIP switch can be used to configure the pulse output to occur when the vehicle enters

the loop detection zone (Pulse-on Entry) or when the vehicle leaves the loop detection zone (Pulse-

on-Exit). (See the Presence Hold Time or Output Relay Pulse Mode section below for details.)

The factory default setting is OFF (Presence Mode).

Sensitivity Boost (DIP Switch 4):

DIP switch 4 can be turned ON to increase sensitivity during the detect period without changing the

sensitivity during the no detect period. The boost feature has the effect of temporarily increasing the

sensitivity setting by up to two levels. When a vehicle enters the loop detection zone, the detector

automatically boosts the sensitivity level. As soon as no vehicle is detected, the detector

immediately returns to the original sensitivity level. This feature is particularly useful in preventing

dropouts during the passage of high bed vehicles. The factory default setting is OFF (no Sensitivity

Boost).

Sensitivity (DIP Switches 5 and 6):

DIP switches 5 and 6 select one of the four (4) sensitivity levels available as shown in the table

below. Use the lowest sensitivity setting that will consistently detect the smallest vehicle that must

be detected. Do not use a sensitivity level higher than necessary.

Switch

Sensitivity Level (-

ΔL/L)

0.32% (0)

0.16% (1) *

0.08% (2)

0.02% (3)

5

OFF

ON *

OFF

ON

6

OFF

OFF *

ON

ON

* Factory default setting.

iii. PC Board Mounted DIP Switches:

Switch

ON

OFF

Factory Default

1

Exit Pulse or Limited Presence

Entry Pulse or True Presence

TM

OFF

2

Two Second Delay

No Delay

OFF

Presence Hold Time or Output Relay Pulse Mode (DIP Switch 1):

When front panel mounted DIP switch 3 is set to PRES, one of two presence hold times can be

selected by means of DIP switch 1 on the two-position, PC board mounted DIP switch (labeled

SW2). Limited Presence and True Presence

TM

modes both provide a Call output when a vehicle

is present in the loop detection zone. When DIP switch 1 is ON, Limited Presence is

selected, and the detector will typically hold the Call outpu t for one to three hours. When

DIP switch 1 is OFF, True Presence

TM

mode is selected, and the detector will hold the Call

output as long as the vehicle is present in the loop detection zone and power is not removed.

True Presence

TM

time applies only for normal size automobiles and trucks and for normal

size loops (approximately 12 ft

2

to 120 ft

2

).

When front panel mounted DIP switch 3 is set to PULSE, one of two pulse output modes can be

selected by means of DIP switch 1 on the two-position, PC board mounted DIP switch (labeled

SW2). The Pulse-on-Entry setting (DIP switch 1 OFF) causes the output relay to provide a 250

millisecond pulse when a vehicle enters the loop detection zone. The Pulse-on-Exit setting (DIP

switch 1 ON) causes the output relay to provide a 250 millisecond pulse when a vehicle exits the

loop detection zone.

The factory default setting is OFF (Pulse-on-Entry / True Presence

TM

).

Output Delay (DIP Switch 2):

A two second delay of the output can be activated by setting DIP switch 1 to the ON position.

Output delay is the time the detector output is delayed after a vehicle first enters the loop detection

zone. If the two second Output Delay feature is activated, the output relay will only be turned on

after two seconds have passed with a vehicle continuously present in the loop detection zone. If the

vehicle leaves the loop detection zone during the two second delay interval, detection is aborted and

the next vehicle to enter the loop detection zone will initiate a new full two second delay interval.

The detector provides an indication that a vehicle is being detected but that the output is being

delayed, by flashing the front panel DET LED at a four Hz rate with a 50% duty cycle. The factory

default setting is OFF (no Output Delay).

III.

Reset:

Pushing the front panel RESET pushbutton or changing any DIP switch position (except 1 or 2) will

reset the detector. After changing the frequency selection switches, the detector must be reset.

IV.

Call Memory:

When power is removed for two seconds or less, the detector automatically remembers if a vehicle was

present and a Call was in effect. When power is restored, the detector will continue to output a Call until

the vehicle leaves the loop detection zone (loss of power or power dips of two seconds or less will not

bring a gate arm down onto cars as they wait at the gate).

V.

Failed Loop Diagnostics:

The FAIL LED indicates whether or not the loop is currently within tolerance. If the loop is out of

tolerance, the FAIL LED indicates whether the loop is shorted (one Hz flash rate) or open (steady ON).

If and when the loop returns to within tolerance, the FAIL LED will flash at a three flashes per second

rate to indicate that an intermittent loop fault has occurred and has been corrected. This flash rate will

continue until another loop fault occurs, the detector is reset, or power to the detector is interrupted.

VI.

Pin Connections (Reno A & E Wiring Harness Model 802-4):

Pin

Wire Color

Function

1

Black

AC Line / DC +

2

White

AC Neutral / DC Common

3

Orange

No Connection

4

Green

No Connection

5

Yellow

Relay, Common

6

Blue

Relay, Normally Open (N.O.)

7

Gray

Loop

8

Brown

Loop

9

Red

No Connection

10

Violet or

Black / White

Relay, Normally Closed (N.C.)

11

White / Green or

Red / White

No Connection

Note: All pin connections listed above are with power applied, loop(s) connected, and no vehicle detected.

VII. Warnings:

Separately, for each loop, a twisted pair should be created consisting of only two (2) loop wires running

the entire distance from the loop to the detector (including runs through all wiring harnesses) at a

minimum of six (6) complete twists per foot. For trouble free operation, it is highly recommended that

all connections (including crimped connectors) be soldered.