Maintenance 8. repairs, Manual operation – Controlled Products Systems Group 106753 User Manual

Page 10

10

FAAC Model 770 24V Underground Swing Gate Operator

At regular intervals, check the structure of the gate and

make sure that the hinges are in perfect working order.

Periodically lubricate the pivot and ball in the support

bracket, through the lubricating bore shown in Fig. 1-

Ref. 13. Make sure that the pivots of the lever systems,

the pinion and the engagement of the lock on the locking

bracket (Fig. 1 - Ref. 5) are always well lubricated, and

check the efficiency of the manual operation.

Whenever you perform a maintenance operation, check

that the anti-crushing system and the safety devices

installed on the automation system are correctly set.

For repairs, refer to an authorized FAAC service center.

7. MAINTENANCE

8. REPAIRS

To restore normal operation, proceed as follows:

1. Push the lever back into its home position (Fig. 17 - Ref. 1).

2. Insert the release key into the lock and turn it as far as it will

turn in the direction opposite the post (Fig. 17 - Ref. 2).

3. Operate the leaf manually until the lock is engaged in the

locking bracket (Fig. 17 - Ref. 3).

4. Close the lid on the lock.

Fig. 17

1

2

3

Fig. 16

1

2

4

3

6. MANUAL OPERATION

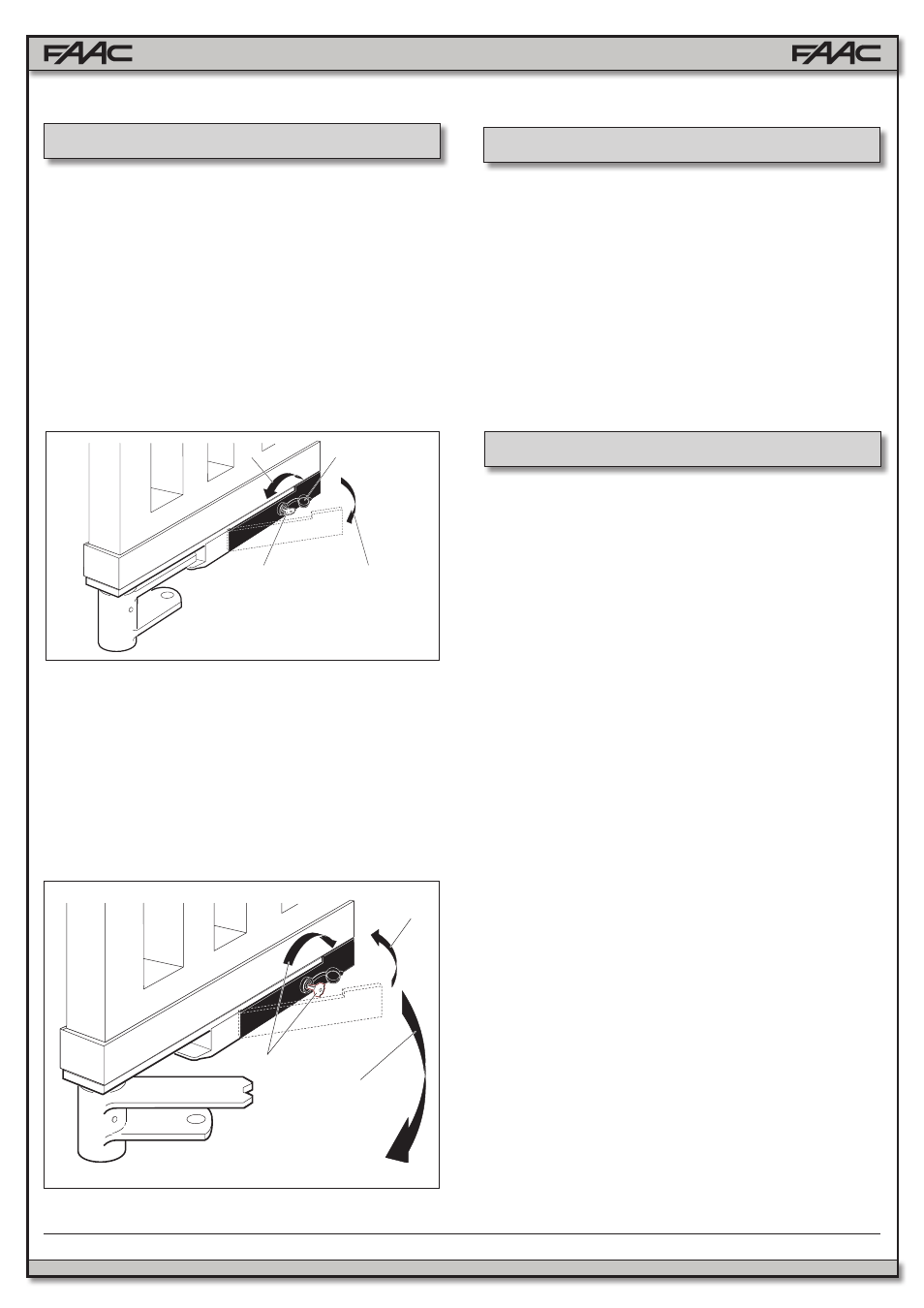

Should the need arise to operate the gate manually because of

a power failure or malfunction, use the release device with key

fitted on the support bracket (Fig. 1 - Ref. 6). The operator can

be released from both the inside and the outside of the gate

To operate the leaf manually, proceed as follows.

1. Open the lid of the lock (Fig. 16 - Ref. 1).

2. Insert the release key in the lock (Fig. 16 - Ref. 2).

3. Turn the key in the direction of the post, as far as it will go

(Fig. 16 - Ref. 3).

4. Pull the lever out (Fig. 16 - Ref. 4).

5. Operate the leaf manually.