Sx dx, Installation steps – Controlled Products Systems Group 104572 User Manual

Page 8

8

FAAC Model 390 24V Articulated Arm Swing Gate Operator

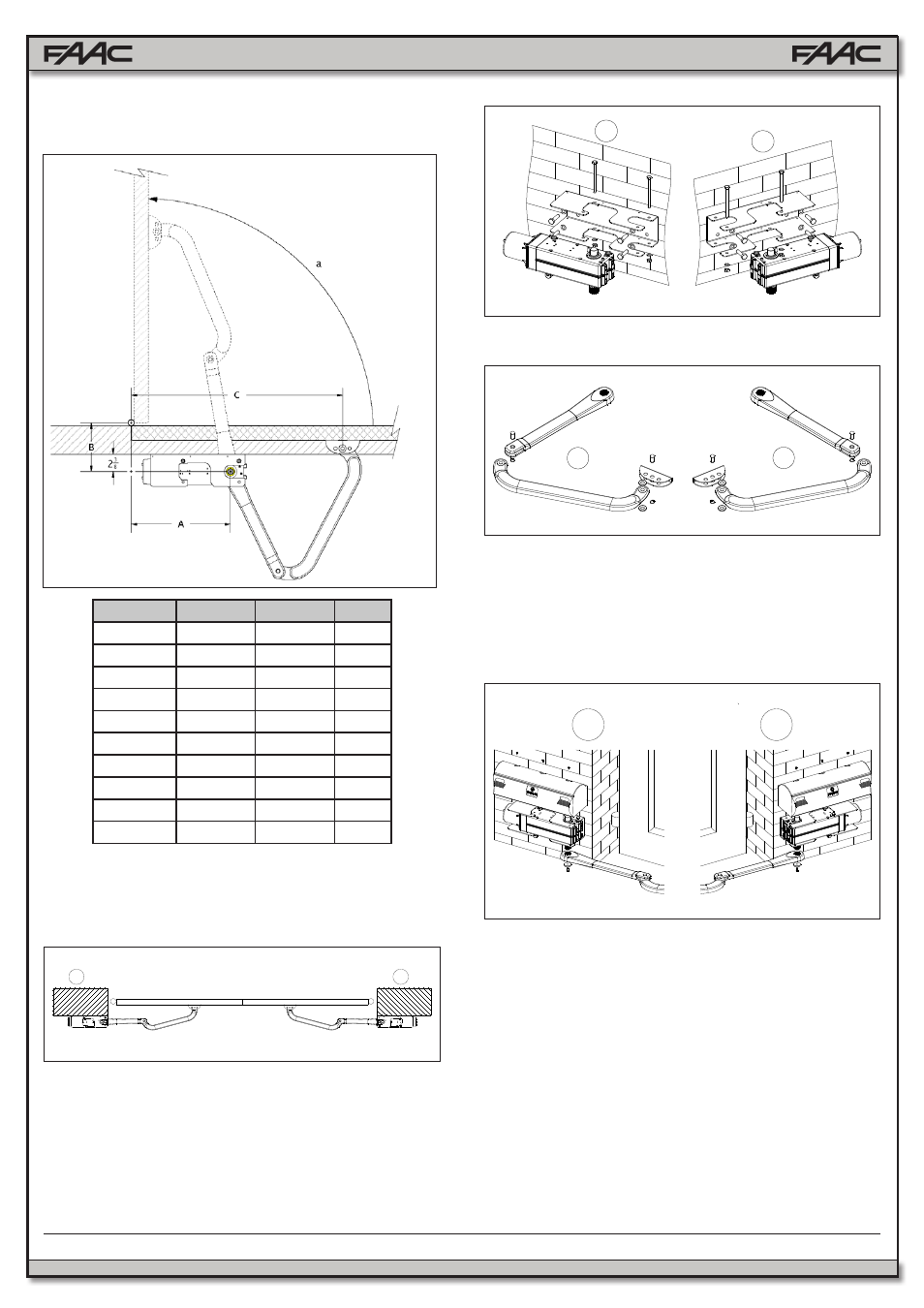

4.2.3. RECOMMENDED DIMENSIONS FOR OUTWARD

OPENING "overhead” swing mounting dimensions

A

B

C (max)

α

2⅜ - 4⅜

4⅜ - 5⅛

28¾

90°

4⅜ - 6¼

4⅜ - 5⅛

28¾

90°

6¼ - 8¼

4⅜ - 5⅛

28

90°

8¼ - 10¼

4⅜ - 5⅛

27½

90°

10¼ - 12¼

4⅜ - 5⅛

27⅛

90°

12¼ - 14⅛

4⅜ - 5⅛

26⅜

90°

2⅜ - 4⅜

7½ - 8¼

23½

120°

4⅜ - 6¼

9 - 9⅞

22

120°

6¼ - 8¼

11⅜ - 12¼

19

120°

8¼ - 10¼

12¼ - 13

17¼

120°

SX

DX

SX

DX

Fig. 8

Fig. 9

Fig. 10

Establish the installation position of the operator by consulting

Figs. 4-6.

4.3.

INSTALLATION STEPS

The operator 390, base-plate and articulated arm are designed

either for right-hand or left-hand (Fig. 7) installation.

• Secure the base-plate to the pilaster, using Ø10 screws

and suitable expansion plugs (Fig. 8), and ensure that it is

perfectly horizontal.

• Fit the gearmotor unit on the base-plate and secure it with

the two screws, nuts and flexible washers (Fig.8).

•

The transmission shaft must always face downward.

•

Assemble the articulated arm and front coupling as

shown in Fig. 9.

•

Fit the straight lever of the articulated arm on the gear-

motor shaft and tighten it with the supplied screw and

washer (Fig. 10).

•

Release the operator (See Chapter 5)

DX

SX

SX

DX

Fig. 7

Fig. 6a

• Measurements in Inches

•

Establish the securing position of the front coupling on the

leaf, observing dimension “C” defined previously (Section

4.2). Check that arm and coupling are perfectly horizontal.

•

The coupling may be welded directly onto the leaf (Fig. 11)

or screwed by using the threaded inserts (Fig. 12).

•

In both cases, temporarily remove the coupling from the

arm in order to secure it.

•

Fit the cover on the operator (Fig. 10).

•

Re-lock the operator (See Chapter 5)

•

Make the electrical connections of the selected electronic

appliance, observing the annexed instructions.