Electrical layout 4. installation, Preliminary checks, Installation dimensions – Controlled Products Systems Group 104572 User Manual

Page 7

7

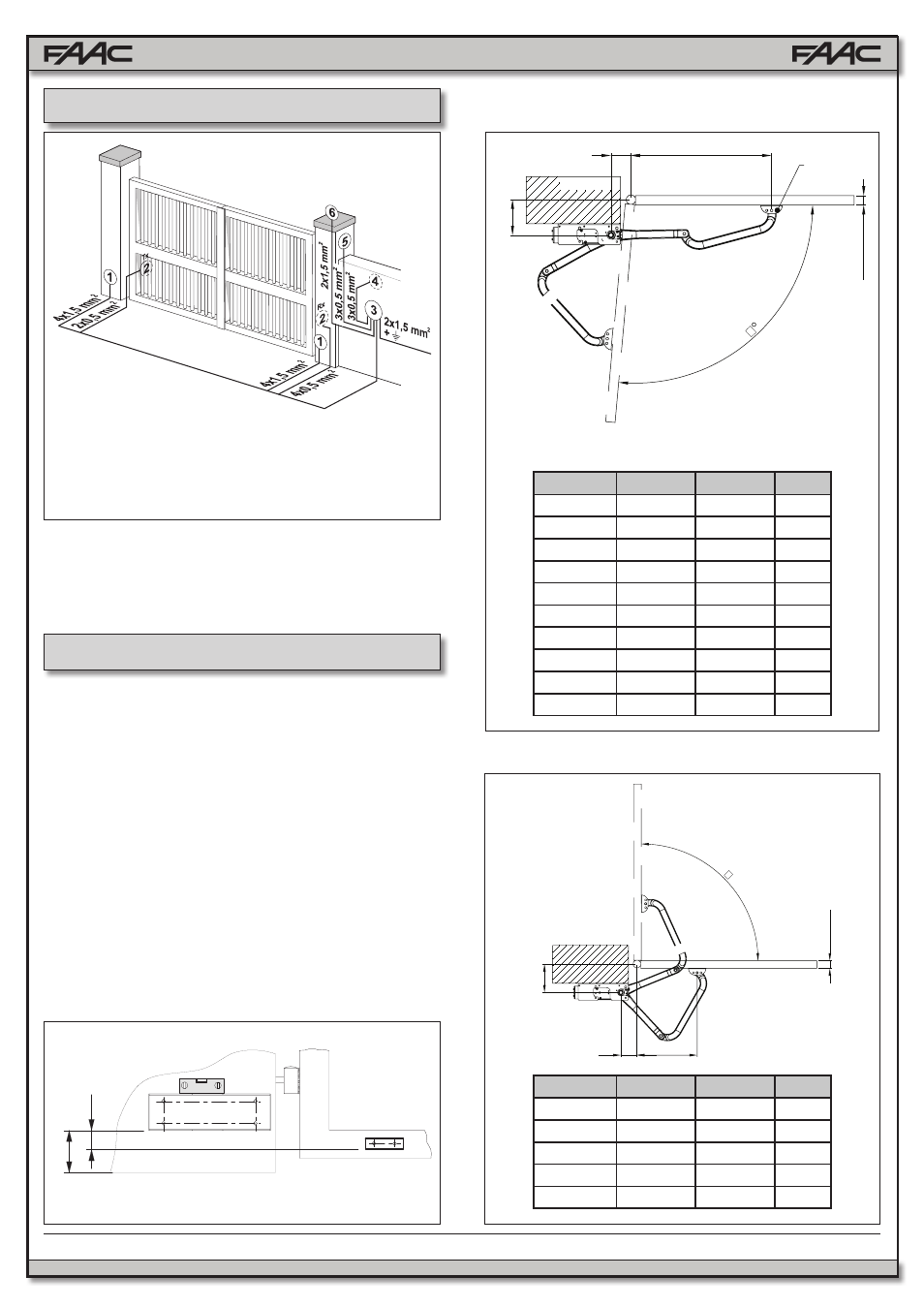

FAAC Model 390 24V Articulated Arm Swing Gate Operator

C

B

A

°

1½ / 2

⅜

1½

7⅞

A

B

C

1½ / 2⅜

X

Fig. 3

Fig. 6

Fig. 4

Fig. 5

4.1.

PRELIMINARY CHECKS

To ensure safety and an efficient automation, make sure

the following requirements are met:

• The gate structure must be suitable for automation. In

particular, make sure it is sufficiently sturdy and rigid,

and that its dimensions are in line with those indicated

in the technical specifications.

• Make sure that the leaves move properly and uniformly,

without any irregular friction during their entire travel.

• Check if hinges are in good condition.

• Make sure the travel limit mechanical stops are pres-

ent.

• We advise you to carry out any metalwork jobs before

installing the automation.

4.2.

INSTALLATION DIMENSIONS

1)

Operators Model 390

2) Photocells

3)

Electronic Equipment

4)

Key-Operated Push-Button

5)

Radio Receiver

6)

Warning Light

1. To lay electrical cables, use adequate rigid and/or

flexible tubes.

2. Always separate low voltage accessories from those

operating at 115V~. To avoid any interference, always

use separate sheaths.

• Measurements in Inches

• Measurements in Inches

Notes:

As for 120° openings, the curved arm must be fixed to

the hole marked with the letter X

3. ELECTRICAL LAYOUT

4. INSTALLATION

4.2.1. RECOMMENDED DIMENSIONS FOR INWARD

OPENING

4.2.2. RECOMMENDED DIMENSIONS FOR OUTWARD

OPENING

A

B

C (max)

α

2⅜ - 4⅜

4⅜ - 5⅛

28¾

90°

4⅜ - 6¼

4⅜ - 5⅛

28¾

90°

6¼ - 8¼

4⅜ - 5⅛

28

90°

8¼ - 10¼

4⅜ - 5⅛

27½

90°

10¼ - 12¼

4⅜ - 5⅛

27⅛

90°

12¼ - 14⅛

4⅜ - 5⅛

26⅜

90°

2⅜ - 4⅜

7½ - 8¼

25½

120°

4⅜ - 6¼

9 - 9⅞

23⅝

120°

6¼ - 8¼

11⅜ - 12¼

21¼

120°

8¼ - 10¼

12¼ - 13

20

120°

A

B

C (max)

α

2⅜ - 4⅜

4⅜ - 5⅛

17

90°

4⅜ - 6¼

4⅜ - 5⅛

15

90°

6¼ - 8¼

4⅜ - 5⅛

13

90°

8¼ - 10¼

4⅜ - 5⅛

11

90°

10¼ - 12¼

4⅜ - 5⅛

9½

90°

• Measurements in Inches

Operators Cable Size

AWG 14 (max 30’)

AWG 12 (max 50’)

AWG 10 (max 100’)