Rewind with load cell + clutch/motor, Process, Closed loop initial set of parameters – Cleveland Motion Controls Quantum Tension Controller REV A User Manual

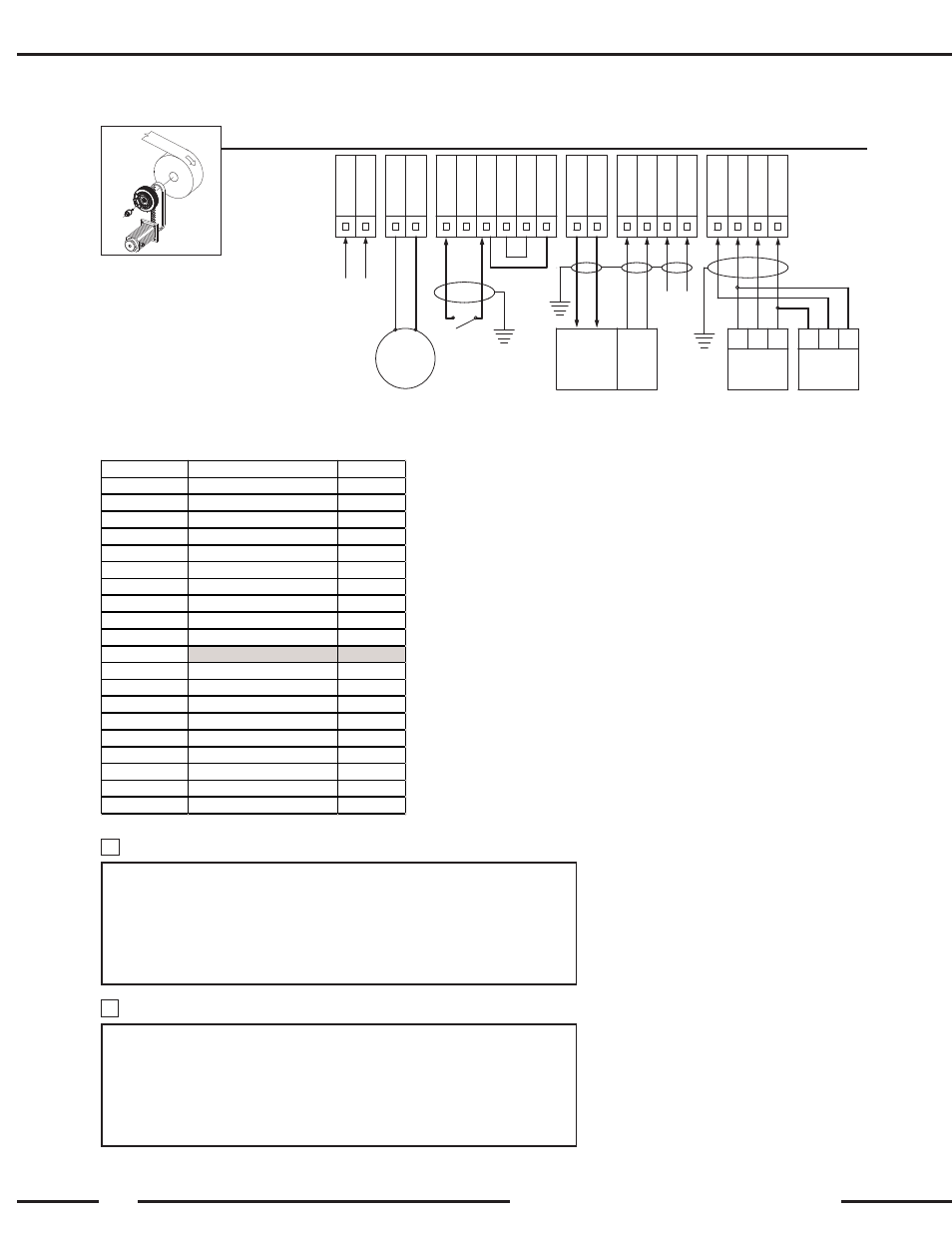

Page 8: Wiring

www.cmccontrols.com

8

Machine / product stopped : B = 0V (OPEN)

Web Tension = HOLD value (Open Loop)

Machine / product running : B = 24V (CLOSED)

Web Tension = SET POINT value (Closed Loop)

Process

Com

+24

C1

C2

V+

A

B

V+

Init

Reg

S1-

Com

S1+

+5V

Com

TC

Com

DM

Com

AO2

+24 V

AC / DC

EMAG

Brake

Jumpers

Drive

Output

-10 - +10V

Web

rotation

Tachometer

0 - 10V

Diam.

Input

0 - 10V

Logic

input B

N.O.

BK

R

WH

BK

R

WH

Load cell

Classic

Load cell

Classic

Wiring

REWIND WITH LOAD CELL + CLUTCH/MOTOR

CLOSED

LOOP

Initial set of parameters

File : Force_clutch_motor.prm

DISPLAY

Line 1

Set Point

Line 2

Measure

FUNCTIONS

Time Delay Start

1

Time Delay Stop

300

Hold

10

INPUTS

Set Point

100

Diameter Filtering

1000

Tachymeter Filtering

100

OUTPUTS

Upper Limit

0

Bottom Limit

10

Power Gain

100

REGULATION Max Effort

P

100 (*)

I

20 (*)

D

0

Measurement Filtering 100 (*)

Open Loop Gain

0

Closed Loop Gain

100

Speed Gain

Calcul 1

Coeff Speed

0

Overspeed

Calcul 2

R

egulation

S

peed

G

ain =

(D

min x

V

l

) / V

r

D

min

[m]

Min web diameter

V

l

[m/min]

Linear speed for 10V output from tachometer

V

r

[RPM]

Max speed of the drive motor

(when set point output =10 V on AO2)

1

O

verspeed =

(S

s x

AO2

max

) / V

r

S

s

[RPM]

Slipping speed (

60

RPM recommended)

AO2

max

[V]

Max output from AO2 :

10

V

V

r

[RPM]

Max speed of the drive motor

(when set point output =10 V on AO2)

2