Ken Tool T601 (38601) CENTER POST TIRE CHANGING SYSTEM User Manual

Page 13

5. To mount the second bead, follow the same procedures. Place your left hand flat

agasinst the sidewall of the tire, pushing down to keep bead below the drop-center

(smallest diameter of the rim). See photo C, p. 12.

B. 5/8” and 3/4” bearing wheel types:

1. Place the rim over the center post with the valve stem facing up.

2. Install the bearing guide with recess side down to prevent bearing damage (see

diagram ). This centers the wheel on the threaded center post. Place one or both

spacer sleeves over post and secure with round nut. Hand tighten only. Caution: Do

not use machine without spacer sleeves. This will damage the threaded mounting

shaft and make it unusable.

3. Once the rim is securely held in place, apply adequate amount of Bead-Eze® (or

similar tire lubricant) to the tire bead. Do not use flammable materials when

servicing tires and wheels. Place tire on rim.

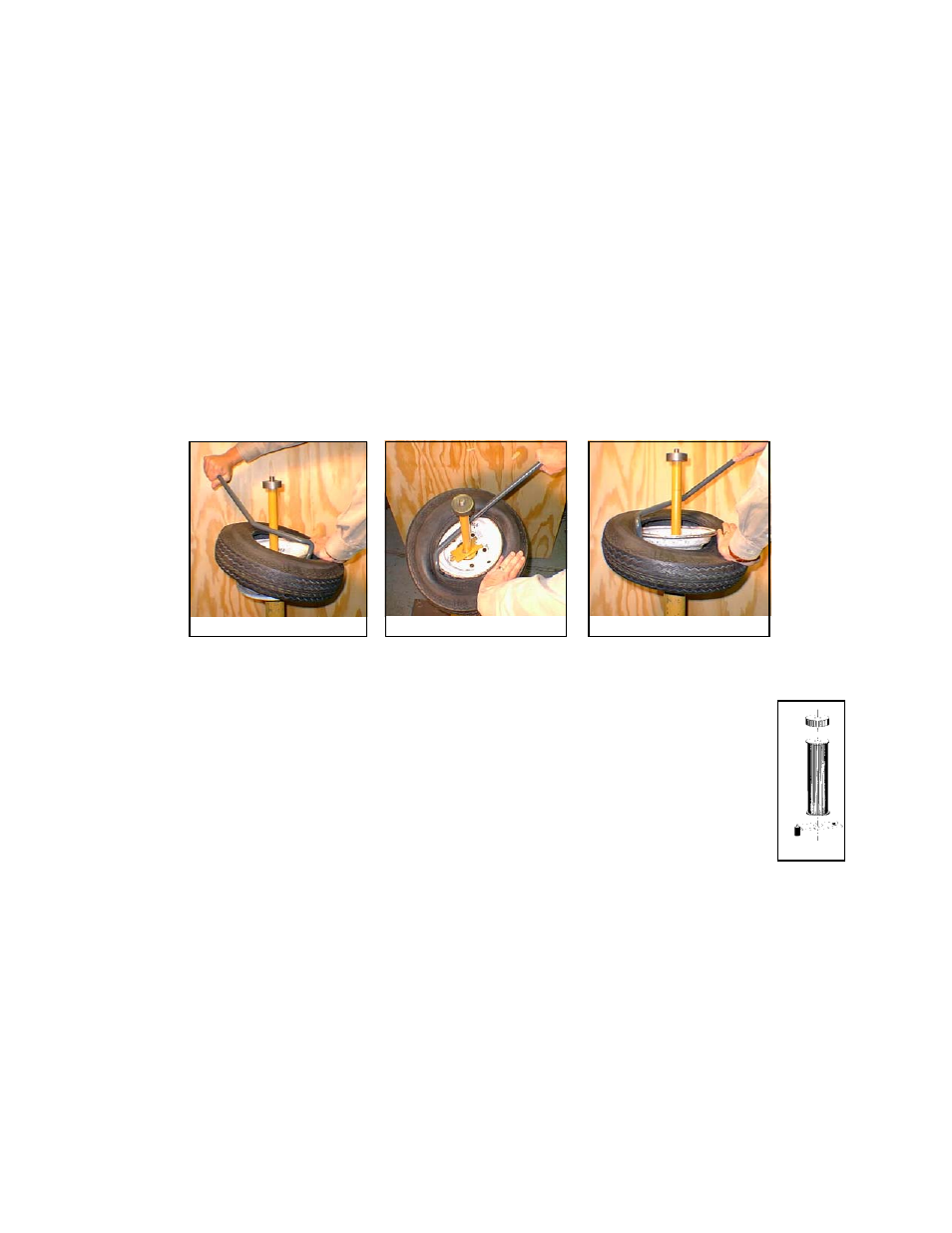

4. Cock the tire on the rim and hook the mount (curved) end of the Tire

Snake™ over the exposed edge of the rim on side nearest you. Place your

left hand flat against the sidewall of the tire to hold in place. Use caution

when mounting to keep fingers from being pinched between rim and bead

as tire is mounted to rim. Grasp the Tire Snake™ at its farthest end, keeping

it parallel with the rim. Pull the bar in a clockwise direction around the

center post until first bead is mounted. See photos below.

5. To mount the second bead, follow the same procedures. Place your left

hand flat against the sidewall of the tire, pushing down to keep bead below the drop-

center (smallest diameter of the rim). See photo C.

Photo C: Mount

Photo A: Mount

Photo B: Mount