Basic adjustments/settings, Manual bypass setting, Fig. 7 – Cashco 9540L P/P User Manual

Page 5: Required tools, Tbl. 2

IOM-9540L

5

the connection port of the actuator casing.

NOTE-

Thread Sealants: If TFE tape is used, make sure

that small pieces of tape will not be “pinched off”

and enter the pneumatic internals. (Liquid thread

sealants are not recommended.)

11. Place temporary fittings and tubing so that the

positioner is able to be supplied with a 20-35 psig

air supply to the “SUPPLY AIR” port of the adapter

block (AB). Supply pressure depends upon actua-

tor bench range; see Table 2. Using a manual

loader, connect a 3-15 psig air source to the

“INPUT (3-15 psig) W” port of the adapter block

(AB).

12. Stroke the valve thru its full travel by varying the

input signal “SIG” span of 3-15 psig. Observe the

feedback linkage to assure that the linkage does

not bind and does experience overtravel. At a 9

psig signal input, the feedback lever should be

approximately horizontal.

IMPORTANT NOTE: If the feedback lever (13) is

turned forcibly against the travel stop pin (20), the

stroke factor lever (19) will be released from rigid

connection (unscrews) to the positioner main shaft

(17). If this occurs, the feedback lever (13) must

be loosened, the main shaft (17) must be retight-

ened to the stroke factor lever (19) by holding the

stroke factor lever (19) firmly against the travel

stop pin (20), while turning the main shaft (17) CW

(viewed from shaft end) using a screwdriver on the

main shaft’s (17) end. Steps 8 thru 11 must be

repeated.

13. Leave temporary air sources as installed for final

calibration, Section V, but turn off the air supply so

that no pressures are induced to the internals.

IV. BASIC ADJUSTMENTS/SETTINGS

A. Required Tools:

The following tools are required for the basic

adjustment:

1.

Screwdriver

2.

Open-end wrench - 6 mm

3.

Feeler gauge 0.6 mm (.024 in)

4.

(2) test gauges - 30 psig (for 20 psig max

bench range); (1) test gauge - 30 psig and

(1) test gauge - 60 psig (for 30 psig max bench

range)

5.

Manual loader/airset

6.

Open-end wrench - 10 mm

7.

Needle-nose pliers; small

8.

#5 Allen wrench (5 mm) (provided)

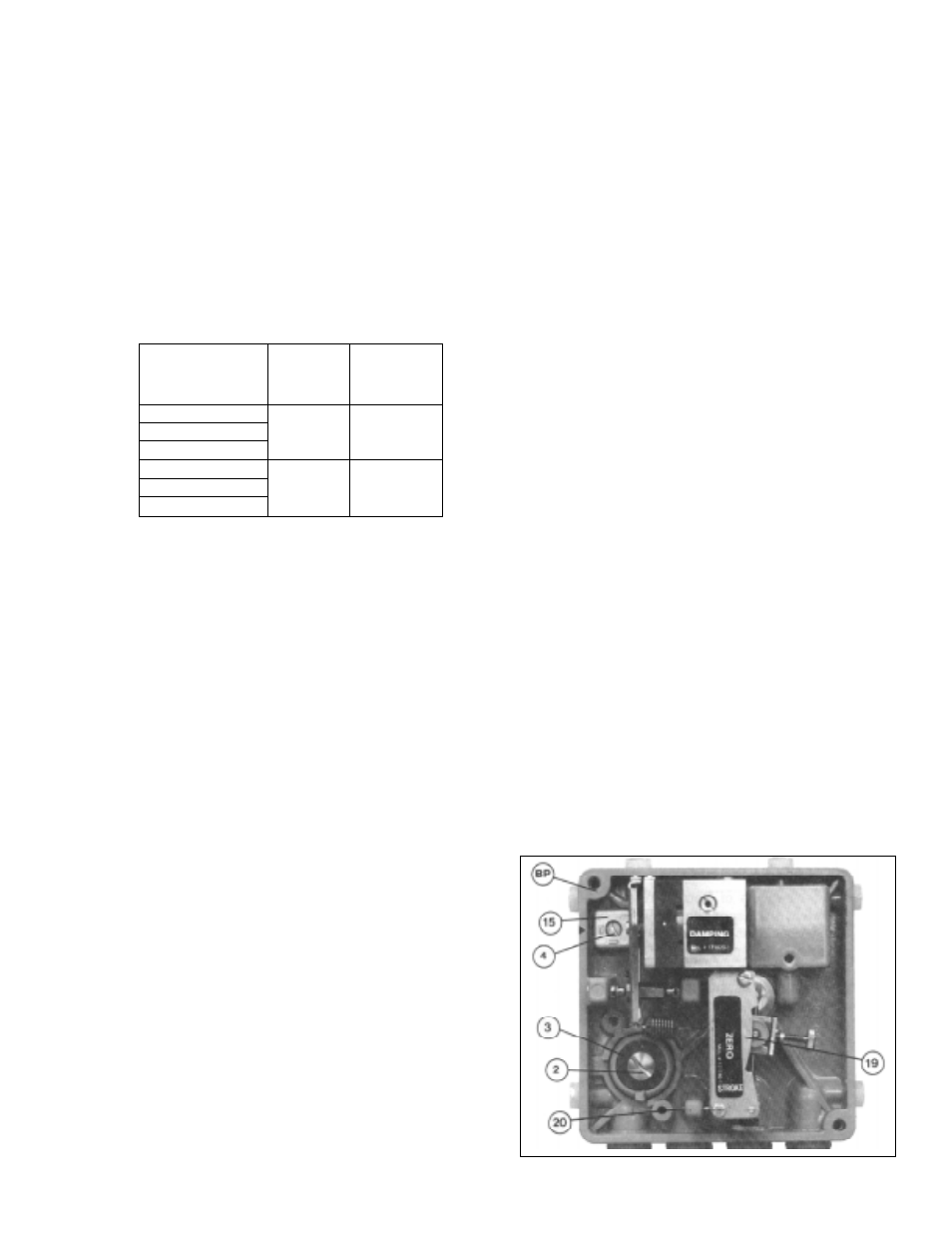

B. Manual Bypass Setting: (See Figure 7)

1.

There are two positions for the pneumatic

bypass switch (3) to be in:

“EIN”-Positioner is active (ON); this is the

factor set position.

“AUS” - Positioner is inactive (OFF), and the

input “SIG" is passed directly to the actuator,

bypassing the positioner internals.

2.

“EIN” or “AUS” are labels cast into the baseplate

(BP). To bypass, loosen the bypass screw (2)CCW

to release the bypass switch (3) rotor; two full

revolutions of the bypass screw (20) will be re-

quired. Rotate the bypass switch (3) CW 90

°

to

move to bypass (AUS); rotate CCW to activate the

positioner (EIN). The bypass switch (3) has a rib

on its outer edge that indicates the position of the

bypass switch (3). When adjustments are com-

pleted, retighten bypass screw (2). DO NOT

LEAVE AT AN INTERMEDIATE POSITION;

PLACE AT “EIN” OR “AUS” ONLY.

NOTE: For picture clarity, all photographs hereafter have

the two internal gages removed.

SECTION IV

Actuator

Supply

Max Supply

Bench Setting

Pressure

Pressure

(psig)

(psig)

(psig)

3-15, 4-15

5-15, 3-10

20

25

8-15, 3-13

6-26, 6-27, 6-30

6-20, 7-28, 9-30

35

40

10-30, 16-30

TABLE 2

Figure 7