Replacing the amplifier, Fig. 13, Trouble shooting guide – Cashco 9540L P/P User Manual

Page 10

IOM-9540L

10

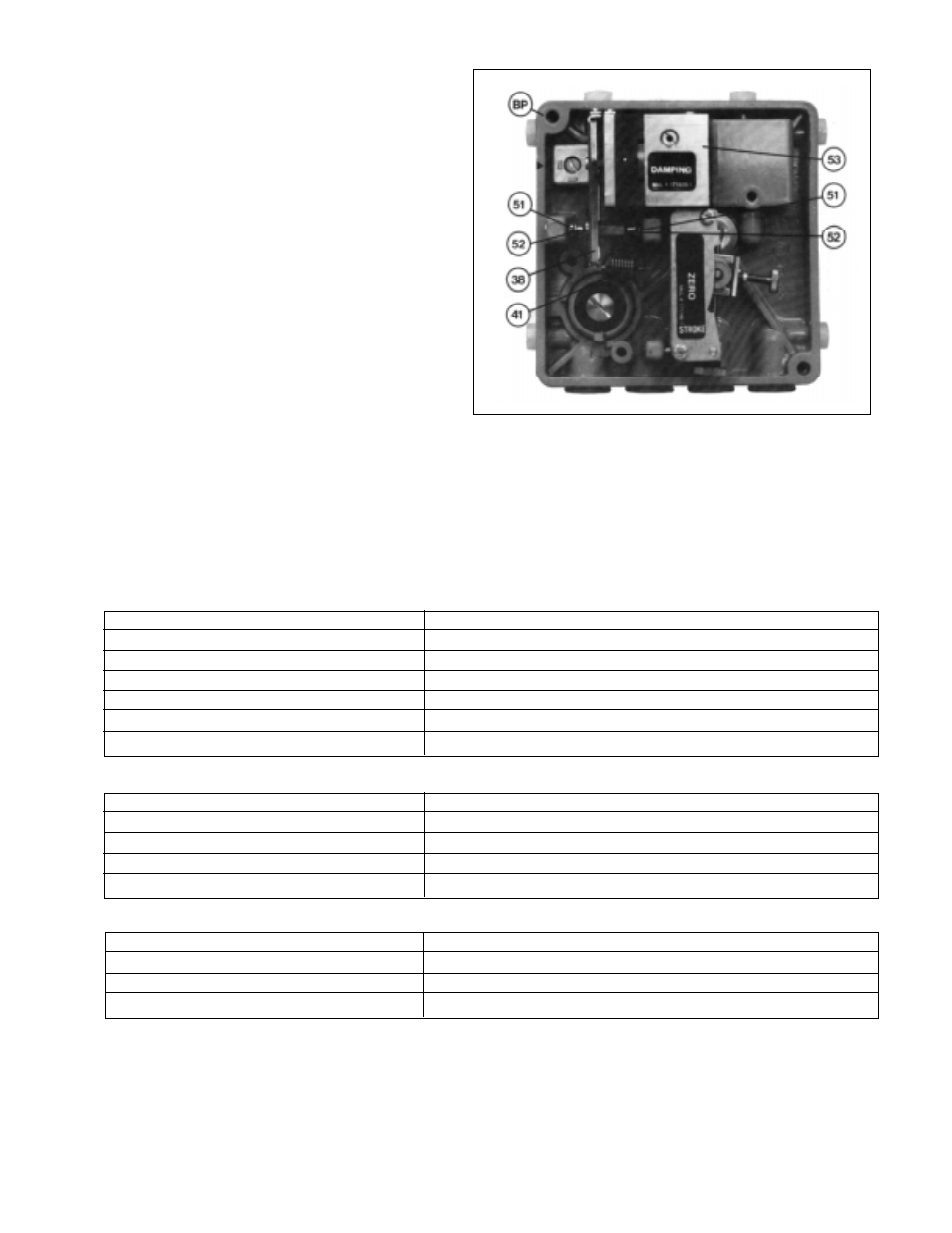

C. Replacing The Amplifier: (See Figure 13)

1.

Unhook the range spring (41) from the flapper

lever (38). (See Figure 11.)

2.

Unscrew and remove the amplifier (53) sub-

assembly; the two amplifier mounting screws are

accessible from the rear of the positioner.

3.

Install a new amplifier (53). Do not forget the

O-rings between the amplifier and the baseplate

(BP) (air baffle). Before tightening, carefully align

the mounting screws, position the amplifier (53) in

such a way that the flappers (52) are concentri-

cally aligned with the nozzles (51).

4.

Hook the range spring (41) onto the flapper lever

(38).

5.

Perform a maintenance basic adjustment and

recalibrate per Sections IV, V and VI.

VII.

TROUBLE SHOOTING GUIDE

1.

Actuator does not respond to applied input signal.

Possible Causes

Remedies

A. Amplifier defective

A1. Replace amplifier (See VI.C.).

B. Pneumatic connections reversed

B1. Check connections.

C. Feedback lever not tightened

C1. Screw feedback lever tight (See III.B.9.).

D. Stroke factor lever is loose on the shaft

D1. Tight shaft.

E. Positioner mounted on the wrong side

E1. Check mounting side in accordance with table in Section III.

F. Changeover plate in the wrong orientation

F1. Check setting accordance with table in Section III.

2.

Output pressure does not reach its maximum.

Possible Causes

Remedies

A. Amplifier throttle dirty

A1. Remove and clean throttle (See VI.B.).

B. Supply air too low

B1. Check supply air pressure.

C. Flappers not parallel with nozzles

C1. Align flappers (See VI.A.d.-f.).

D. Supply air filter dirty

D1. Replace filter.

3.

Actuator moves to end position.

Possible Causes

Remedies

A. Positioner mounted on wrong side

A1. Check mounting side in accordance with table in Section III.

B. Feedback lever not tightened

B1. Tighten feedback lever.

C. Stroke factor lever loose on shaft

C1. Tighten shaft (See Section III.B.).

Figure 13

SECTION VII