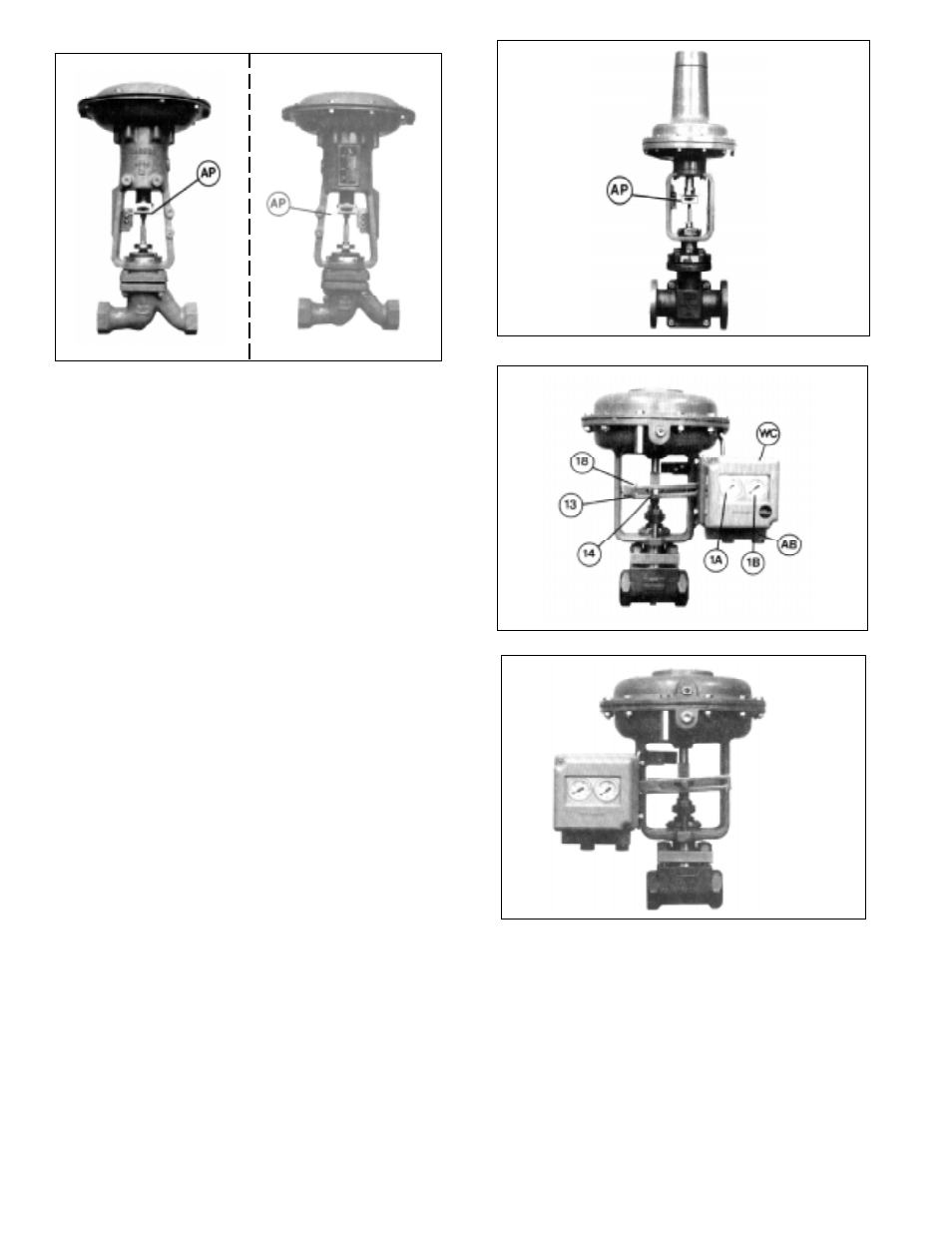

Fig. 5b model 964, Fig. 5c model 521, Fig. 6a – Cashco 9540L P/P User Manual

Page 4: Fig. 6b

IOM-9540L

4

4.

If the control valve does not have an accessory

plate (AP) installed, the actuator stem must be de-

coupled from the valve stem. (Refer to the valve/

actuator instructions for de-coupling procedure.)

Place accessory plate (AP) as indicated in Fig-

ures 5A, 5B or 5C.

5.

If it is necessary to re-orient an existing accessory

plate (AP) that is secured to the valve’s stem by a

jam nut, loosen the jam nut so that the accessory

plate (AP) is loosened enough that it can be tipped

and rotated to the proper frontal position. Re-

tighten the accessory plate (AP) jam nut. Attach

the stem feedback carrier bolt (14) to the acces-

sory plate (AP) using the Tinnerman nut.

(Note: Above is true for the 987 and 2296 actuators.

For Models 30, 55D, 55R, 115D and 115R actuators,

separate accessory plates are required for “left” or

“right” mounting positions.)

6.

Remove the positioner cover (WC). Orient the unit

so that the DAMPING & GAIN labels are top/

center, and the gauges (1A & 1B) are right side up.

7.

Fasten the positioner baseplate (BP) to the mount-

ing bracket (12) using the two mounting screws

(11) (See Figure 4).

8.

With the actuator at zero stroke (“LOAD” = 0 psig;

i.e. no air to actuator diaphragm), attach the

feedback lever (13) on the main shaft (17) (Figure

4) of the positioner with the feedback carrier bolt

(14) located in the feedback lever’s (13) slot. The

compensating spring (18) must be located above

the feedback carrier bolt (14) when the unit mount-

ing is on the right (See Figure 6A), and below the

feedback carrier bolt (14) when the mounting is on

the left. (See Figure 6B). Hand tighten socket cap

screw (21) (Figure 4); DO NOT WRENCH

TIGHTEN!

9.

Press the stroke factor lever (19) (See Figure 7) of

the positioner’s internals against the travel stop

pin (20) and hold firmly in place. Place the #5 Allen

wrench into the head of the socket cap screw (21),

and tighten while still holding stroke factor lever

(19). Tighten firmly. (A 5 mm, #5 metric Allen

wrench should be provided with the unit.)

10. Install tubing fittings with acceptable thread seal-

ant and tubing from the unit’s 1/4” NPT (female)

“OUTPUT 1” port of the adapter block(AB) up to

Figure 5B: (Model 964 w/left and right mounting positions)

Figure

6A

Figure 6B

Figure 5C: (Model 521 w/Model 30 actuator)