Cashco 764PD Pressure Controller User Manual

Page 9

IOM-764P / PD

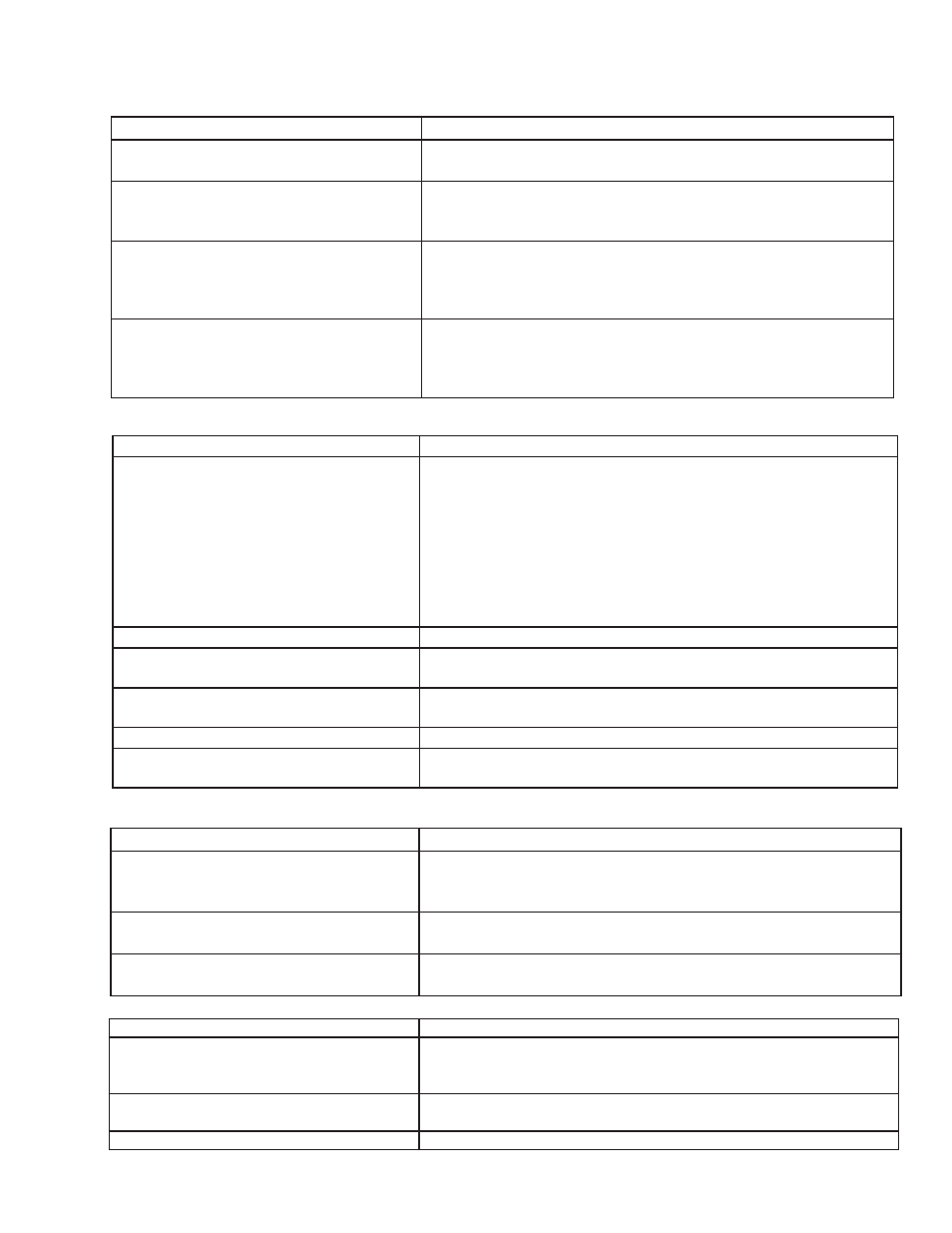

9

Possible Cause

Remedy

A. Insuffi cient PB

A. Increase PB in 1/8 rev. increments by turning the needle valve

CCW. Reset setpoint as required (Max PB at 1-1/2 revs.).

B. Improper air supply.

B1. Supply pressure too high. Reduce airset output supply pres

sure to 15-18 psig.

B2. Air supply unsteady. Replace airset.

C. Pulsing process sensing.

C1. Snub process needle valve as far as practical without shutting

off. Observe process gauges carefully.

C2. Poor location of process pressure tap. Evaluate and consider

relocation.

D. Non-Correctible process dynamics.

D1. Bypass control valve positioner and directly load actuator.

D2. Review sizing of control valve, may be oversized. Use re

stricted trim if necessary.

D3. Consult factory

Possible Cause

Remedy

A. Restricted fl ow(s).

A1. Open process needle valve adequately. Disconnect tubing and

blow sensing line.

A2. Check equivalent output tubing line length against those

indicated herein in Section 11.7. Relocate controller, or

consider adding an air booster or positioner at the control

valve.

A3. Check for mashed or pinched tubing.

A4. Installation debris. Air blow line.

A5. Ice in lines. Use dry air supply.

B. Insuffi cient air supply.

B. Increase supply up to 18-20 psig.

C. Too much PB.

C. Decrease PB in 1/8 rev. increments. Reset setpoint as

required.

D. Improper range selection.

D. Use the lowest range possible, if available to obtain the best

response.

E. Too large actuator.

E. Add an air booster or positioner at the actuator.

F. Use of alcohols, glycols in freezing

weather; dissolved lubricant on O-rings.

F. Remove sensor sub-assembly and lubricate O-rings.

Possible Cause

Remedy

A. Sensing diaphragm loose at screwed

connection to housing or adapter.

A. Piping weight is cantilevered off of process connections or

instrument air connections causing unscrewing, and effecting

internal clearances. Change piping or add supports as required.

B. Bent sensing diaphragm.

B. Inspect diaphragm; replace if bent. Bent diaphragm indicates an

overpressure condition; correct if necessary.

C. Air supply debris.

C1. Provide a cleaner air supply or piping source.

C2. Ice in lines. Correct as necessary.

3. Erratic Operation; Rapid Cycling.

4. Sluggish operation; slow action.

5. Calibration Erratic; frequent setpoint adjustments.

6. Leakage of process fl uid.

Possible Cause

Remedy

A. Sensing diaphragm O-ring failure.

A1. Improper installation causing overheating by not provifi ng a

loop seal for hot condensing fl uids; i.e. steam.

A2. Chemical attack. Consult factory.

B. For 764PD, pusher post O-ring failure.

B1. Same as A1. above.

B2. Same as A2. above.

C. Diaphragm failure.

C. Corrosive attack. Consult factory.