Cashco 764PD Pressure Controller User Manual

Page 6

IOM-764P / PD

6

7. Remove the three sensor O-rings (5) from the

sensor (2.1).

NOTE: Typically, additional dis-assembly of

the sensor sub-assembly (2) is not required.

If it is necessary to replace any of the sensor

sub-assembly parts (2.1, 2.2, 2.3, 2.4, 2.5) a

complete new sensor sub-assembly must be

installed. Contact the factory for assistance.

8. Take all the metal parts except the gauge (11)

and nameplate (10) and clean in suitable solvent.

Clean and air blow all drilled air passages.

9. Install pressure gauge (11) into the pneumatic

hous ing (1) using suitable thread sealant.

10. Install new O-rings (5) on sensor sub-assembly

(2). Check the two dimensions given in Figure 10

of the sensor sub-assembly as “fi nal set tings”.

2. Remove cap screws (19) and nuts (18). Re move

diaphragm upper case (13) and upper diaphragm

O-ring (16). Remove diaphragm (12), and SST

diaphragm cover (17) if sup plied. Remove lower

case diaphragm O-ring (16) and pusher post O-ring

(23) for 764PD. In spect for any corrosion damage

and/or per ma nent deformation of the diaphragm

(12) and diaphragm cover (17); if bent, replace.

3. For 764PD, separate at the screwed joint between

the diaphragm lower case (14) and the adapter (21)

turning the diaphragm case (14) CCW (viewed from

di a phragm case end). When separated, remove

the adapter O-ring (22) and replace. Reinstall the

adapter (21) and diaphragm lower case (14).

4. For the 764PD, replace diaphragm O-ring (16) for

the lower case (14) and the pusher post O-ring

(23).

5. Replace diaphragm (12) and diaphragm cover(s)

(17), if supplied. Assure that the di a phragm cover

(thin SST material) (17) is placed on side(s) ex-

posed to the process fl uid(s). (764PD requires both

sides to be cov ered, if supplied with diaphragm

covers (17).

6. Replace with new upper case diaphragm O-ring

(16), upper case (13), and cap screws with nuts

(19 and 18).

7. Recalibrate per Section VI.

C. Pneumatic Circuit Overhaul:

1. Remove output pressure gauge (11) and test

cal i bra tion. If gauge is off ± 2 psi (±0.14 Bar)

recommend replacement.

2. Remove lower diaphragm case (14) from the

pneu mat ic housing (1) at the point where screwed

to geth er. Rotate the diaphragm case (14) CCW

(viewed from di a phragm case end) to loosen. For

764PD: Remove adapter (21) together with lower

diaphragm casing (14) at the screwed joint be-

tween the pneumatic hous ing (1) and the adapter

(21). Rotate the adapt er (21) CCW (viewed from

diaphragm case end) to loosen. Once loos ened,

ori ent the unit along a hor i zon tal axis to pre vent

internal parts from fall ing from within when sepa-

rated. DO NOT RE MOVE PUSHER-POST (24)

FROM 764PD.

3. Remove sensor plate (15.1) (15).

4. Remove nameplate screw (9), nameplate (10),

and four housing screws (8). Grasp the sensor

sub-assembly (2) end plate (2.2), and pull it

outwards from the housing (1). Watch for the

sensor pin (2.4) as the sensor sub-assembly

(2) is withdrawn, as pin (2.4) easily falls out and

could be lost.

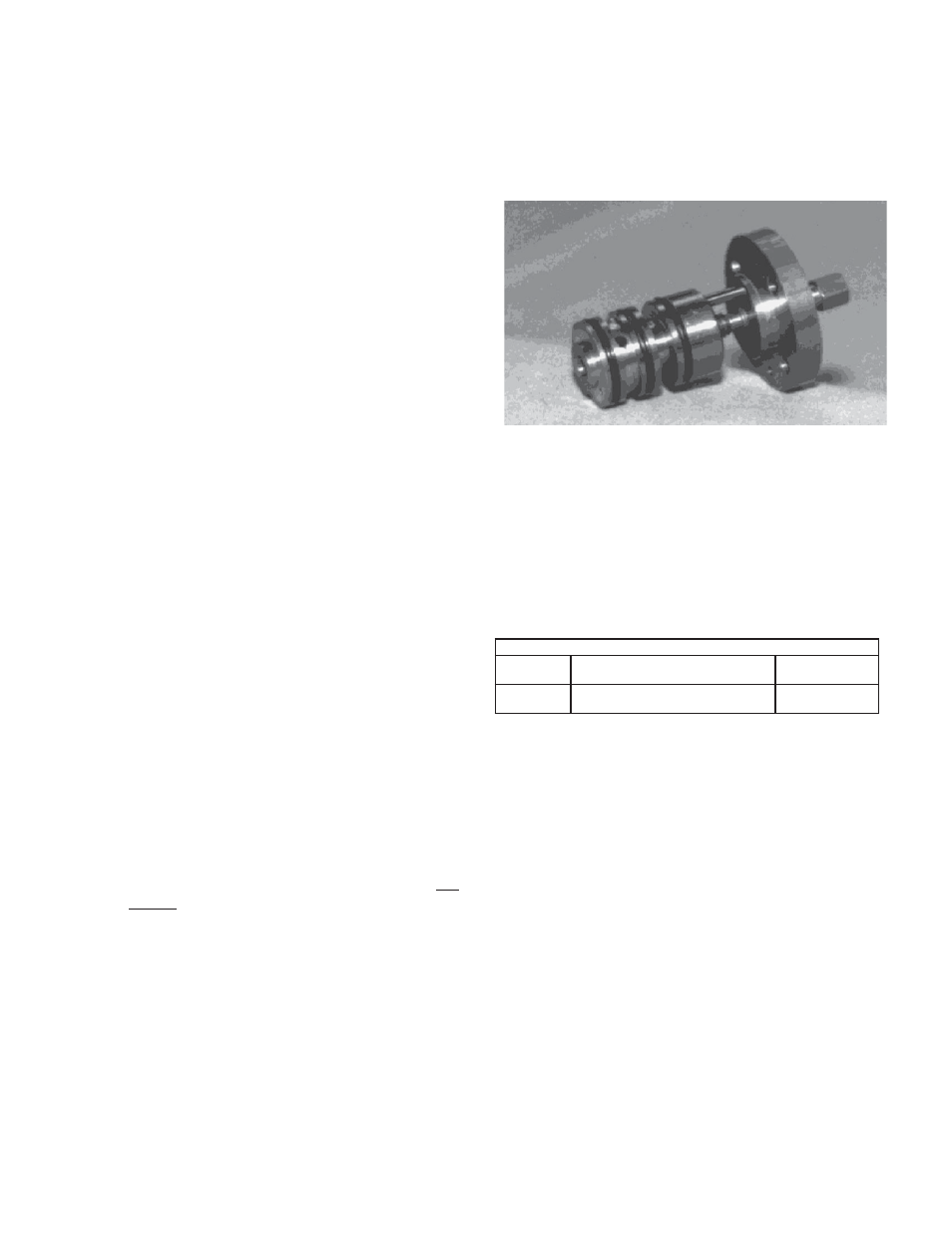

Figure 9: Sensor Sub-Assembly (2)

5. Remove sensor plate O-ring (6).

6. Take note of the position of the PB needle

valve (3) by rotating it CW until it seats: count

the exact amount of rotation in 1/8 rev. in cre-

ments; record the count in Table 3. Re move

the PB needle valve (3) with O-ring (7) by

rotating CCW. Remove O-ring (7).

TABLE 3

Part

DESCRIPTION

OF ROTATION

NO. OF

REVOLUTIONS

PB Needle

Valve (3)

No. of Revolutions rotated CW to

fully seat