Iom-148 – Cashco Premier User Manual

Page 11

IOM-148

11

LOAD

VENT

CLOSE

OPEN

Rotation

4. Loosen all casing (1,2) fl ange bolting (27, 28,

41, 42) two revolutions. Pry apart the casings

(1,2) if “stuck” together.

5. In one revolution increments loosen all op-

pos ing nuts (41, 42) until the short bolting

(27, 41) disengages and can be removed.

Con tin ue loosening extension nuts (42) in

the alternating, one revolution pattern ensur-

ing that the cas ings (1, 2) are being “pushed

apart”, until the extension bolting (28, 42) is

disengaged and removed.

6. Lift the upper casing (1) upwards and away

from the lower casing (2) and set upper case

(1) aside.

VENT

LOAD

OPEN

Rotation

CLOSE

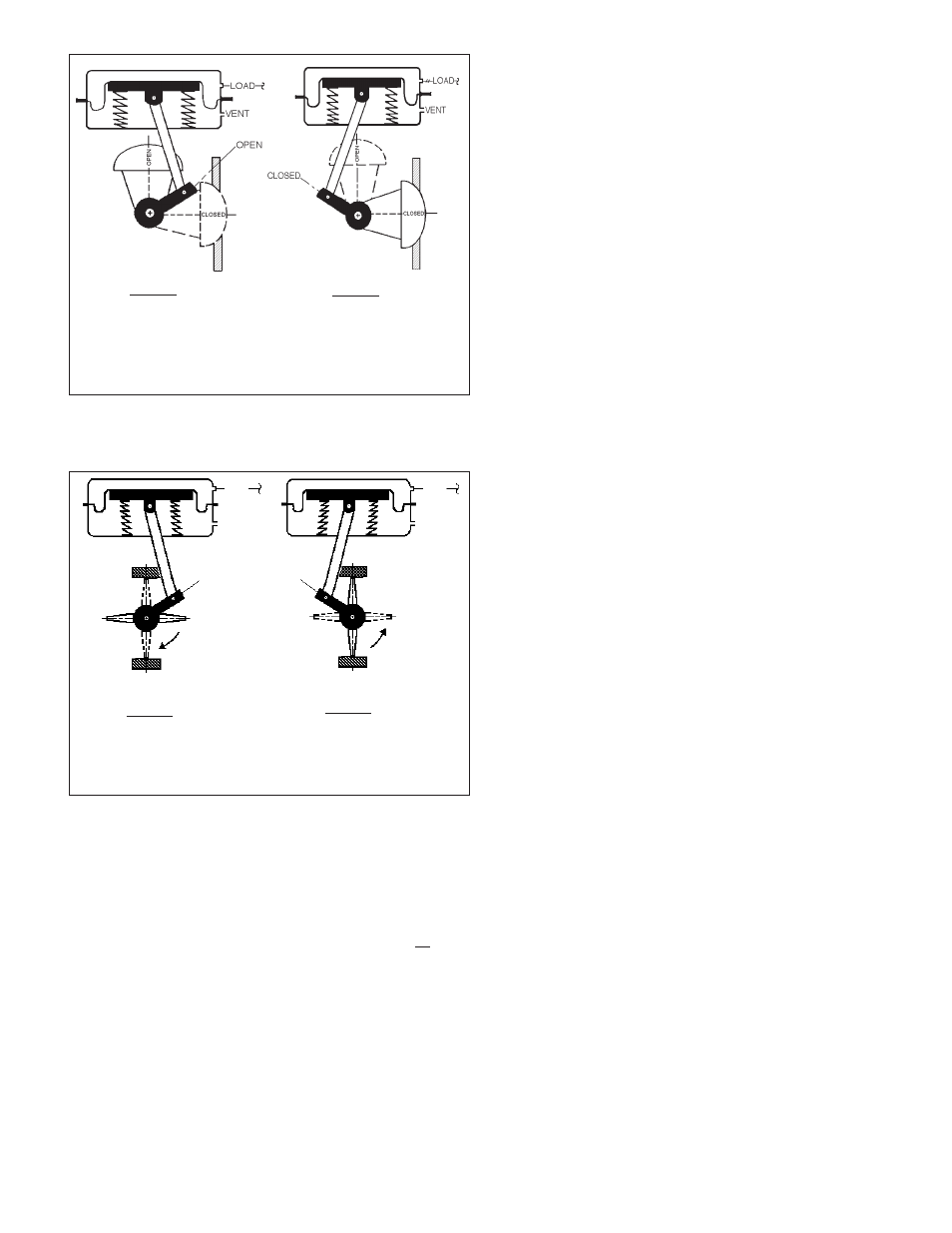

CCW-TO-OPEN

ATC-FO

(DIRECT)

Push Down-to-Close

CCW-TO-OPEN

ATO-FC

(REVERSE)

Push Down-to-Open

CCW-TO-OPEN

ATC-FO

(DIRECT)

Push Down-to-Close

CCW-TO-OPEN

ATO-FC

(REVERSE)

Push Down-to-Open

Figure 10

Ranger Plug vs. Lever Arm vs. Actuator Ori en ta tion

Figure 11

Premier Plug vs. Lever Arm vs. Actuator Ori en ta tion

NOTE: To switch “action” requires locating actuator stem

to opposite side of valve stem.

NOTE: To switch “action” requires locating actuator stem

to opposite side of valve stem.

7. Remove pivot screw (25) by rotating CCW

(viewed from above), and seal (56).

8. Pry diaphragm washer (52) loose. Clean

wash er (52) of any rubberized sealant.

9.

Prior to diaphragm (6) removal, inspect to see

where a diaphragm (6) leak may have been

caused by wearing against the upper case (1)

at any point. Inspect the upper case (1). NOTE:

The diaphragm (6) is a rolling di a phragm and

should NOT touch the upper case (1) at any

point of the piston’s (3) up wards/downwards

travel. If there is side move ment of the piston

(3), further dis as sem bly for inspection of range

springs (11) is man da to ry. If there is topside

wear, uptravel stop washer (54) is not prop er ly

adjusted.

10. Remove diaphragm (6) and discard.

11. Clean surface of piston (3) of any foreign ma-

terial that could cause a premature failure of

diaphragm (6) if cov ered. Turn diaphragm (6)

“inside-out”. Place diaphragm (6) onto piston

(3) centered over the center bolt hole in piston

(3); ensure that the smooth black sur face of

di a phragm (6) is on the “pressurized air-side”.

12. Place silicone sealant, Dow-Corning “Silastic”

#732 RTV or equal, around the diaphragm’s

(6) center bolt hole opening. Lay diaphragm

washer (52) onto sealant and centered over

bolt hole. Replace seal (56) on top of washer

(52).

13. Place a tool around the skirt circumference

of the piston (3) to secure during tightening;

use tape or similar material to prevent this tool

from leaving sharp edges that could damage

the new diaphragm (6). Place Locktite #242,

or equal, thread sealant onto the threads of

pivot screw (25); engage and tighten screw

(25) to 15-20 ft-lbs (21-27 N-m) torque. NOTE:

Piston (3) must be held from rotating to pre vent

the multiple nested range springs (11) from

tilting away from a common vertical centerline

be tween hubs of lower case (2), piston (3) and

range spring (11).

14. Fold the diaphragm (6) skirt from its inside-

out ori en ta tion, down and around the piston’s

(3) skirt. Using a rounded-end tool, push the

diaphragm (6) down between the lower cas ing

(2) sidewall and the piston’s (3) skirt, forming

a “valley”. Work diaphragm (6) to ensure that

all folds or “puckers” are taken away. Press

the di a phragm’s (6) lower/outer beaded edge

into the groove. Again, smooth out all folds or

puckers in diaphragm (6).