Warning, Iom-148 – Cashco Premier User Manual

Page 10

IOM-148

10

10. Reorient body assembly (BA) with respect to

the actuator assembly (AA). Rejoin the body

assembly (BA) to the actuator assembly (AA)

as described in this section, V.I. Ensure prop er

plug (Ranger (6)) or disc (Premier (3.1)) po si tion

prior to reinstalling lever arms (5). Ensure that

the lever arms (5) are “centered” within the arm

housing (4), and with respect to the actuator

stem linkage (8) (9) (10) (43) (44).

11. Recalibrate the unit (AA) (BA) and its positioner

((PA)).

D. Changing Failsafe Action:

1. Model 148 actuator (AA) is fi eld-reversible for

failsafe action with no additional parts required.

2. It is possible that both of the following can occur

together for the degree of disassembly under-

taken:

a. Failsafe action reversed.

b. Change in actuator mounting position.

NOTE: This section will be limited to the pro ce dures

for 2.a. above. If 2.b. is also desired, then it will be

necessary to reference Sub sec tion C. here in for the

added procedural steps as required.

This subsection will thus be limited as in di cat ed as

follows (reference Figures 10– 11 herein for be gin-

ning and end graphic orientations).

NOTE: Valve stem always goes CW to

“close”, viewed from stem-end.

4. Separate the actuator assembly (AA) from

the body assembly (BA) as described in this

Sec tion, V.B.1. through V.B.10.

5. Rotate plug (Ranger (6)) or disc (Premier (3.1))

position 90° to new failsafe position.

6. Slide actuator assembly (AA) that has been

rotated 180° back over the stem-end (Ranger

(7)) (Premier (3.2)). Align bolt holes between

arm housing (4) and valve yoke (12).

7. Reengage bolting (24) securing arm housing

(4) to yoke (12). Torque bolting (24) to 30-35

ft-lbs (40-47 N-m).

8. Ensure that the reinstalled lever arms (5) are

also rotated 180° in the same reference as the

actuator as sem bly (AA) was rotated. (NOTE:

The repositioned arms (5) will appear to have

only changed relative position by 90° in an oth er

plane.) Ensure the lever arms assembly (5)

is “centered” within the arm housing (4), and

with respect to the actuator stem (8) (9) (10)

(43) (44).

9. Rejoin the body assembly (BA) to the actuator

as sem bly (AA) as described in this Section,

V.I.

E. Diaphragm

Replacement:

1. Place unit assembly (AA) (BA) onto a fl at work

bench with actuator upper casing (1) on top

side; i.e. handwheel (58), if supplied, on top

side. Place a matchmark between actuator

casings (1) (2).

2. Ensure that all air pressure is released from

actuator assembly (AA) casing (1).

3. Ensure that manual handwheel (58) operator

is fully rotated upwards by loosening locking

lever (59) and ro tat ing CCW (viewed from top

side) as far as possible.

SPRING UNDER COMPRESSION. Prior to re mov ing

fl ange bolting (27, 28, 41, 42) re lieve range spring

(11) compression by rotating the handwheel or

adjusting screw assembly (58) CCW (viewed from

above handwheel (58) until all spring com pres sion

is re lieved. Fail ure to do so may result in fl ying

parts that could cause personal injury.

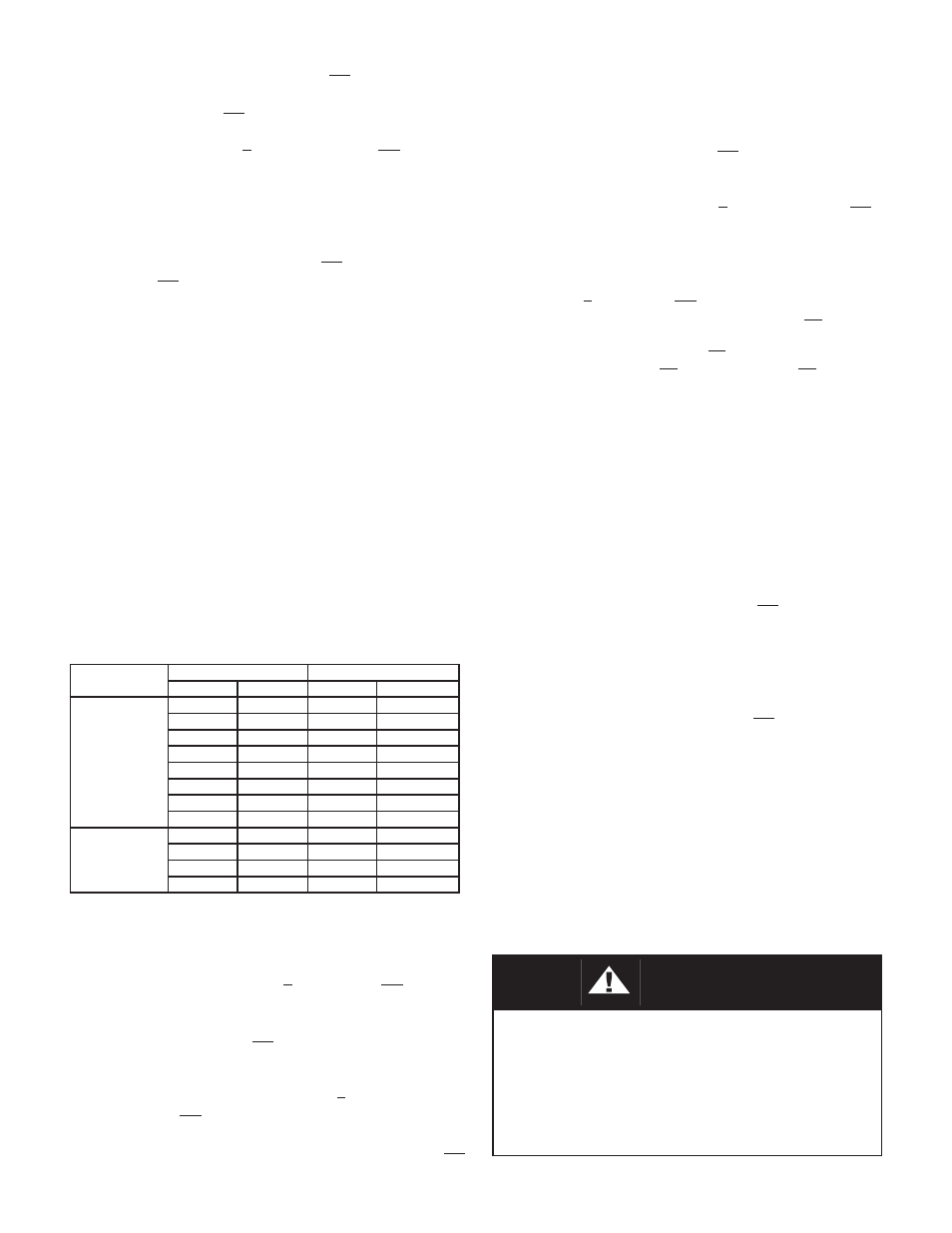

Product

Begin

End

Position

Action

Position

Action

Ranger QCT

“A”

ATO-FC

“B”

ATC-FO

“C”

ATO-FC

“D”

ATC-FO

“E”

ATO-FC

“F”

ATC-FO

“G”

ATO-FC

“H”

ATC-FO

“B”

ATC-FO

“A”

ATO-FC

“D”

ATC-FO

“C”

ATO-FC

“F”

ATC-FO

“E”

ATO-FC

“H”

ATC-FO

“G”

ATO-FC

Premier EZO

or

Premier

Unlined

“A”

ATO-FC

“B”

ATC-FO

“C”

ATO-FC

“D”

ATC-FO

“B”

ATC-FO

“A”

ATO-FC

“D”

ATC-FO

“C”

ATO-FC

WARNING

3. To reverse actuator (AA) failsafe action ba si cal ly

requires:

a. Moving lever arms (5) from left side of valve’s

stem (Ranger (7)) (Premier (3.2)) to right

side, or vice versa. This is ac com plished by

removing actuator assembly (AA) from body

assembly (BA) and ro tat ing actuator (AA)

180° about the ac tu a tor’s stem linkage (8)

(9) (10) (43) (44).

b. Rotating plug (Ranger (6)) or disc (Pre mier

(3.1)) by 90°; ie. from “closed” po si tion to

“open” position, or vice versa.

c. Reconnecting actuator (AA) to body (BA)

with lever arms (5) also rotated 180°.