Smartap, Water quality monitor, Inter-component connections – Hydrotech 12301_12302_12303 Series ADVANCED REVERSE OSMOSIS WATER TREATMENT SYSTEMS User Manual

Page 6

2

SMARTAP

®

WATER QUALITY MONITOR

WaterGroup’s 12303 Series Reverse Osmosis Systems incorporate a proven performance indicator. Our patented Smartap

®

Water

Quality Monitor uses dual probe LOGIC PULSE MEMORY technology to accurately indicate membrane performance. A split-

second power pulse compares feed water Total Dissolved Solids (TDS) level with that of the product water. Then, by reversing the

polarity of the electronic pulse, the probes are cleaned and kept free of chemical plating. A nine-volt alkaline battery provides power

to the Monitor. For optimum monitor performance, the battery should be replaced each time

system is sanitized.

NOTE: Monitor Troubleshooting Indicators and Common Solutions are shown in Table 4 on Page 15.

Push Button Actuated Smartap

®

- 12303 Series

Pressing a test button located on the manifold cover activates monitor. When button is pressed, and momentarily held down,

monitor reports membrane status by illuminating a light located next to test button. A green light means system is operating

normally. A yellow light indicates system needs servicing (membrane may be depleted or fouled). While the button may be

pressed at any time, the most accurate readings are obtained when the system is making water.

INTER-COMPONENT CONNECTIONS

Connections between cold water supply line, RO Module, storage tank, product water faucet, and drain line are accomplished

using plastic tubing and push-together quick-connect type fittings.

PLASTIC TUBING

1. Cut tube ends square and straight. Do not deform

tube (i.e., cause tube to compress its diameter so it is

no longer round).

2. Make sure outer surface of tube is clear of marks or

scratches for a length equal to twice tube diameter.

This allows "O" ring to seat properly against tube.

3. Avoid sharp changes in direction when routing

tubing. Sharp turns cause tubing to flex and deform,

which reduces its flow capacity and may increase

lateral stress on the fittings, causing leakage.

QUICK-CONNECT FITTINGS

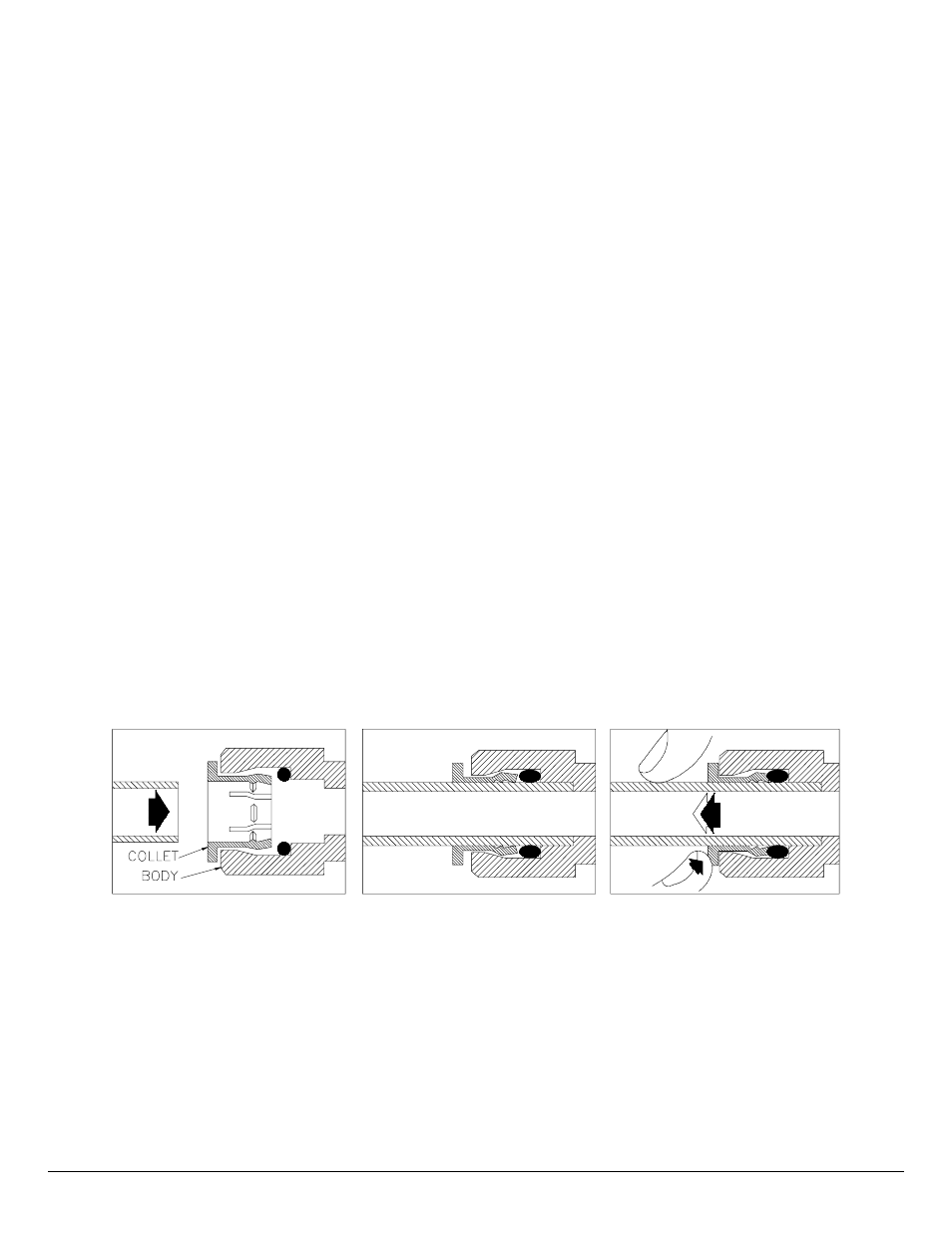

Fittings consist of two parts: a Body and a colored Collet.

Collet color corresponds to tubing color to be used at that

connection (Figure 2.A.).

1. To install a tube, push it through Collet until it seats

firmly at bottom of fitting (Figure 2.A and 2.B.).

2. To remove a tube, push and hold Collet against Body

while pulling tube out (Figure 2.C.).

A. Push tube through Collet into Body.

B. Tube must seat firmly at bottom of

fitting.

C. Push Collet against Body to release

tube.

Figure 2:

How to Use Quick-Connect Fittings